Scroll to:

Structure and properties of an aluminum-matrix composite reinforced with zirconium carbide particles

https://doi.org/10.17073/1997-308X-2025-5-51-59

Abstract

This study examines the structure and mechanical properties of aluminum-matrix composites (AMCs) with varying contents of the ZrC reinforcing phase, produced by powder metallurgy. Elemental mapping together with hardness measurements indicate a uniform distribution of ZrC particles in the matrix. The effects of mixing time (1–6 h), compaction pressure (636–1910 MPa), and sintering time (1–2 h) on density, porosity, and properties were investigated. With increasing ZrC content, the composite’s mechanical properties improve, and correlations among density, porosity, hardness, and strength are observed. An increase in sintering time has little effect on density and porosity; after sintering, hardness decreases due to annealing. Local agglomeration of ZrC at grain boundaries may weaken interfacial bonding between aluminum and the reinforcement. Strengthening arises from load transfer, Orowan strengthening, and thermally induced dislocations due to the coefficient-of-thermal-expansion mismatch between the particles and the matrix. Efficient load transfer during compression testing requires good particle–matrix interfacial contact; dislocation–particle interactions generate Orowan loops, contributing to the observed strengthening.

Keywords

For citations:

Khazin M.L., Apakashev R.A., Adas V.E. Structure and properties of an aluminum-matrix composite reinforced with zirconium carbide particles. Powder Metallurgy аnd Functional Coatings (Izvestiya Vuzov. Poroshkovaya Metallurgiya i Funktsional'nye Pokrytiya). 2025;19(5):51-59. https://doi.org/10.17073/1997-308X-2025-5-51-59

Introduction

Modern mechanical engineering, including the mining industry, is increasingly characterized by the use of new materials. The growing demand for lightweight materials with high specific strength, excellent high-temperature strength, and corrosion resistance stimulates active research and development of advanced high-performance materials [1–4].

Among light-weight materials with low density, aluminum-matrix composites (AMCs) occupy a leading position. The use of aluminum and its alloys as a matrix material continues to expand, finding broad applications in numerous industrial sectors due to their high strength and ductility, excellent thermal conductivity and corrosion resistance [5–7], as well as their relatively low cost compared to other light metals such as Mg and Ti [4; 8].

The global market for metal-matrix composites was estimated at USD 224.82 billion in 2023. It is projected to grow from USD 239.21 billion in 2024 to USD 369.29 billion by 2032, demonstrating a compound annual growth rate (CAGR) of 5.58 %. The increasing demand for lightweight materials in the mechanical engineering, automotive, and aerospace industries is expected to further stimulate key market drivers and contribute to market expansion1.

The main limiting factor for the use of aluminum alloys is their relatively low hardness. Therefore, various reinforcements are incorporated into the matrix to enhance the physical and mechanical properties of aluminum-based materials. Metal-matrix composites (MMCs) are produced by different methods, including stir casting, die casting, spray forming, hot pressing, dynamic compaction, ultrasonic cavitation, physical vapor deposition, mechanical alloying, liquid-metal infiltration, and powder metallurgy (PM) [1; 2; 9; 10]. Most commercial MMCs are produced by liquid-phase methods with mechanical stirring, which makes it possible to obtain components of various sizes and geometries. However, these techniques have several drawbacks: low wettability of reinforcement particles by the molten matrix and the difficulty of achieving a uniform composite structure. Upon cooling and cessation of stirring, the reinforcement particles tend to distribute non-uniformly in the aluminum matrix, often forming agglomerates [1; 11; 12]. As a result, the composite may exhibit nonuniform mechanical behavior.

Unlike liquid-phase techniques, PM methods provide a uniform distribution of the dispersed phase within the aluminum matrix, usually prevent the formation of undesirable phases, and ensure strong interfacial bonding between the matrix metal and the reinforcing particles.

The PM method is energy-efficient, cost-effective, and technologically versatile for producing both simple and complex components of required dimensions. In recent years, PM processing has proven to be efficient and competitive compared with conventional casting methods in the fabrication of metal-matrix composites reinforced with ceramic particles. Composites fabricated by powder metallurgy generally exhibit lower density and higher porosity than those produced by stir casting; however, the reinforcement particles are uniformly distributed in the metallic matrix, unlike in stir-cast materials.

Aluminum-matrix composites produced by various methods are widely used in mechanical engineering [13], shipbuilding [14], electrical engineering [15], medicine [16] the aerospace [17] and defense [18; 19] industries, and even in consumer products [20].

Reinforcements typically include oxides, carbides, nitrides, fly ash, and carbon powders [1–3; 21; 22]. The choice of reinforcing particles depends on the intended application of the composite. The most commonly used dispersoids are SiC, TiC, ZrC, TiB2 , B4C, Al2O3 , and Si3N4 . Among them, zirconium carbide (ZrC) is one of the most suitable reinforcing materials for wear-resistant applications, seals, bearings, crucibles in the nuclear industry, and electronic devices. ZrC is characterized by a high melting point, specific strength, hardness, and corrosion resistance [23]. However, there are very few studies examining the effect of ZrC addition on the physical and mechanical properties of aluminum-matrix materials [24].

The aim of the present study is to investigate the structure and physical and mechanical properties of dispersion-strengthened aluminum-matrix composites reinforced with zirconium carbide (ZrC) particles.

Research methodology

The objects of study were aluminum-matrix composites containing different amounts of the ZrC reinforcing phase. Aluminum powder grade GOST 6058-73; 99 % purity; 250–450 µm) was used as the matrix. Zirconium carbide (ZrC) powder (GOST 28377-89; 40–100 µm) was served as the reinforcement.

The aluminum and zirconium carbide powders were mixed in a polystyrene cylinder rotating at 100 rpm for 1–6 h, with the rotation direction reversed every 15 min to enhance homogeneity.

The homogeneous powder blend was cold-pressed in a PGR-400 uniaxial hydraulic press using a hardened 40Kh steel die (ID 10.2 mm); industrial oil was applied to lubricate the die walls. The green compacts were sintered at 640 °C for 1–2 h under a protective carbon-powder layer and then furnace-cooled to room temperature.

SEM micrographs and EDS elemental maps of the aluminum-matrix composite were acquired on a Vega LMS (Tescan, Czech Republic) scanning electron microscope equipped with an Xplore30 EDS system (Oxford Instruments, UK). The microstructure was also examined using an Olympus BX61 research optical microscope (Olympus Corp., Japan).

The actual density was determined by measuring mass on an AND GR-300 electronic analytical balance (A&D Company Ltd., Japan), with volume obtained geometrically from micrometer measurements. Vickers hardness was measured on the sample surfaces using an ITV-30-AM tester (Metotest LLC, Neftekamsk, Russia) tester under a 25 N load and 15 s dwell; in accordance with GOST R ISO 6507-1-2007, five indents were made per sample. Compressive strength was measured on a MIM 2-20-2 universal testing machine (GOST LLC, Moscow, Russia) at a crosshead speed of 0.2 mm/s (GOST 25.503-97), with simultaneous stress–strain curve acquisition.

Results and discussion

Density and porosity are primary parameters for many applications. After cold compaction of the initial powder blend, the density of the material was measured in both the compacted and sintered states and compared with the theoretical density calculated by the rule of mixtures. The actual density was determined from the mass-to-volume ratio. Porosity was determined as the ratio of the difference between the theoretical and actual densities to the theoretical density. In estimating porosity, the theoretical density was assumed to remain unchanged during sintering because the composite constituents are mutually insoluble.

To select the optimal compaction pressure, trial runs were performed (Table 1). At P = 636 MPa, the compacts were friable, weak, and failed under slight load. Beginning at Р = 950 MPa, dense compacts were obtained. Further increases in compaction pressure produced only minor changes in density (γ); therefore, all subsequent experiments used 980 MPa.

Table 1. Effect of compaction pressure on the density and porosity of the samples

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Analysis of the effect of compaction pressure shows that density increases with increasing reinforcement (carbide-phase) fraction (Table 1), owing to the higher density of the ZrC particles. After sintering, the density decreases. Theoretical densities exceed the measured values due to residual porosity, which likewise increases with increasing reinforcement content in the matrix.

With increasing reinforcement content, the porosity of the compacts initially rises linearly and then slows down, stabilizing at 7–10 wt. % reinforcement. After sintering, the porosity increases due to the expansion of air trapped during mixing of the initial powder blend. This expansion enlarges the pore volume and causes a corresponding change in the linear dimensions of the samples. Excessive addition of reinforcement particles also leads to matrix swelling of the sintered samples. Such porosity variations are consistent with the findings reported by other authors [1; 11].

According to the experimental data, both the “green” and sintered densities are governed by the combined and interacting effects of several factors, including compaction pressure, sintering conditions, and the compressibility of the reinforcing particles. As a result, the green and sintered densities deviate from the theoretical density of the composites.

Increasing the sintering time from 60 to 120 min had almost no effect on density and porosity, whereas for aluminum-matrix composites reinforced with SiC or Al2O3 , an increase in sintering time from 60 to 90 min was reported to enhance density [11].

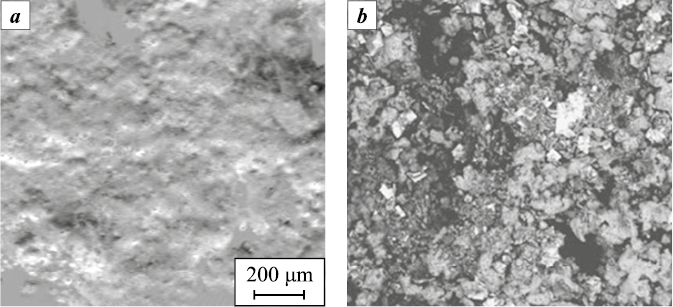

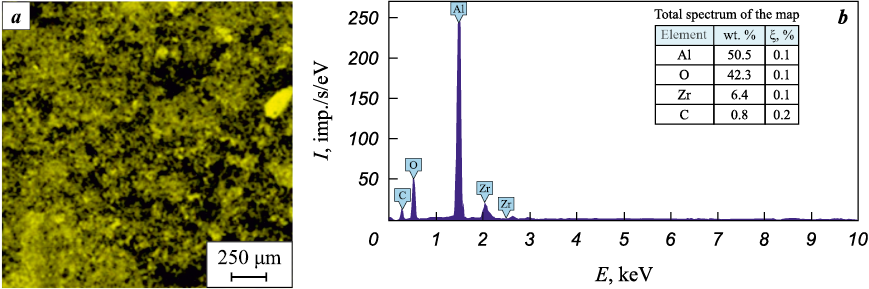

The surface morphology and elemental distribution of the synthesized samples are shown in Figs. 1 and 2. In all cases, a smooth and relatively even surface was observed. The measured surface roughness of the sample cross section was Ra = 1.0–1.2, corresponding to fine turning. Elemental mapping confirmed a sufficiently uniform distribution of the constituent elements.

Fig. 1. SEM images of the surface of an Al–5%ZrC sample

Fig. 2. Elemental distribution map and corresponding EDS spectrum |

The high detected oxygen content, and correspondingly lower total aluminum content, are explained by the formation of an Al2O3 film on the aluminum surface exposed to air (2 mol Al → 3 mol O). According to the analysis, the ratio was 1.87 mol Al and 2.64 mol O. This oxygen amount oxidizes most of the surface aluminum (1.76 mol Al), leaving 0.11 mol Al unoxidized.

Hardness is one of the key parameters directly influencing the strength, impact toughness, fatigue strength, and wear resistance of metal-matrix composites. It is well known that hardness testing is one of the most informative and rapid methods for assessing mechanical properties.

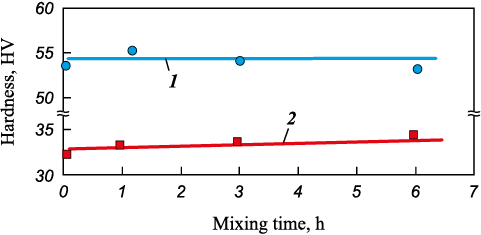

For the composites investigated in this study, variation of the mixing time from 1 to 6 h had virtually no effect on hardness (Fig. 3).

Fig. 3. Effect of mixing time on the hardness of Al–4%ZrC samples |

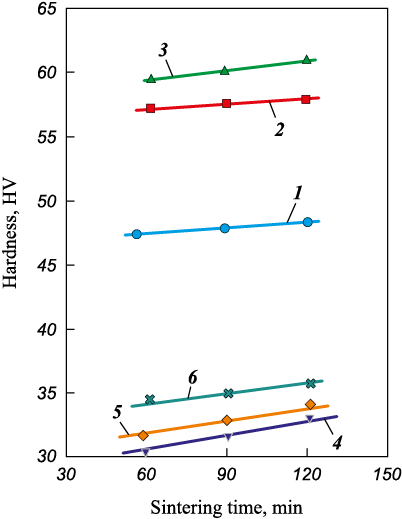

Increasing the sintering time from 60 to 120 min caused a 3.7–8.6 % increase in hardness (Fig. 4). However, as the reinforcement content increased, the relative hardness change decreased, approaching a steady value of 3.7–3.8 %.

Fig. 4. Effect of sintering time on the hardness of the samples |

To assess the uniformity of particle distribution, hardness measurements were taken along the polished surface of the sintered samples at 2.5 mm intervals. The small variation in hardness (±2.6 %) confirmed uniform particle dispersion in the aluminum matrix, consistent with the elemental maps.

With increasing ZrC content in the aluminum matrix, the composite hardness increased (Table 2). After sintering, hardness decreased due to annealing. In addition, clustering of ZrC particles at grain boundaries may weaken interfacial bonding between aluminum and the reinforcement.

Table 2. Effect of composition on the hardness of composites

| ||||||||||||||||||||

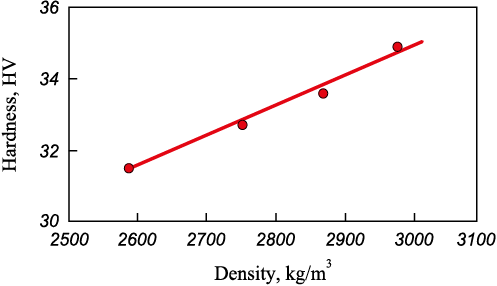

Previous studies have reported a correlation between hardness and density (or porosity) of the samples [1; 3; 6; 7]. A similar proportional relationship between hardness and density (porosity) was also observed in this study (Fig. 5).

Fig. 5. Effect of density on the hardness of Al–ZrC samples after sintering |

The compressive strength of the composites was determined by compression testing. Unlike tension tests, not all materials can be brought to failure under compression, as ductile metals such as aluminum tend to deform into thin plates.

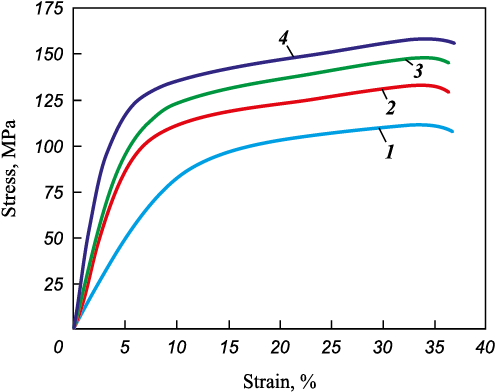

With increasing reinforcement content, the compressive strength increased similarly to hardness. Composites containing carbide particles exhibited a substantial strength improvement compared with the unreinforced aluminum matrix, indicating that ZrC particles provide a strong strengthening effect. As the ZrC content increased, both the ultimate strength and yield strength of the composites rose (Fig. 6). The strengthening can be attributed to the higher dislocation density and the role of carbide particles as barriers to dislocation motion.

Fig. 6. Compression stress–strain curves of the samples |

The relative strength increase of the composites compared with the aluminum matrix ranged from 20 to 50 %. The addition of carbide particles to an aluminum alloy has a positive effect on mechanical properties. The obtained results are consistent with the reported compressive strength of Al–ZrC composites produced by powder metallurgy [24] and by friction stir processing method [25].

Several strengthening mechanisms contribute to the improved performance of metal-matrix composites, the most important being thermal-expansion mismatch and elastic-modulus mismatch between the matrix and the reinforcement (Hall–Petch relationship and Orowan mechanism).

In the studied composites, strengthening arises from load transfer from the matrix to the reinforcement, Orowan strengthening, and the generation of internal thermal stresses due to the difference in the coefficients of thermal expansion (CTE) between the reinforcement particles and the aluminum matrix. Effective load transfer between the ductile matrix and hard ceramic reinforcement particles during tension or compression occurs when good interfacial contact exists between the two phases.

Interactions between dislocations and reinforcement particles enhance the composite strength according to the Orowan mechanism. The presence of dispersed reinforcement particles in the matrix leads to the formation of dislocation loops as dislocations bypass the particles.

Conclusion

Based on the results of the conducted study, the following conclusions can be drawn:

1. Fabrication of Al–ZrC composites by the powder metallurgy method ensures a uniform distribution of zirconium carbide particles within the aluminum matrix, as confirmed by microstructural observations and hardness measurements.

2. Increasing the zirconium carbide content from 0 to 10 wt. % leads to higher density and porosity of the aluminum-matrix composite. The porosity of the samples initially increases linearly with reinforcement content, followed by a slowdown and stabilization at 7–10 wt. % reinforcement.

3. The hardness and strength of the composites increase proportionally with reinforcement content. With a zirconium carbide content of up to 10 wt. %, the hardness and strength of the composites rise by 11 and 52 %, respectively.

4. Increasing the mixing time from 1 to 6 h has little effect on the hardness of the composite material: the relative change was 0.5–0.8 % for green compacts and 2.6–3.2 % for sintered samples.

5. With an increase in sintering time from 1 to 2 h, hardness of the samples rises from 3.7 to 8.6 %, but as the reinforcement content in the matrix increases, it decreases and approaches a steady value of 3.7–3.8 %.

References

1. Aynalem G.F. Processing methods and mechanical properties of aluminium matrix composites. Advances in Materials Science and Engineering. 2020;2020(2):1–19. https://doi.org/10.1155/2020/3765791

2. Konopatsky A.S., Yusupov Kh.U., Corthay S., Matveev A.T., Kovalskii A.M., Shtansky D.V. High-strength composite materials based on aluminum reinforced by micro and nanostructures (mini review). Powder Metallurgy аnd Functional Coatings. 2018;(4):62–72. (In Russ.). https://doi.org/10.17073/1997-308X-2018-4-62-72

3. Kumar S.R., Armstrong M., Sivaneswaran M., Prakash V.S., Prasad S.S., Vishnu Sankar B.P. Characteristics enhancement of mechanical properties of aluminum metal matrix composites reinforced with silicon carbide using stir casting technique. SAE Technical Paper. 2024;2023-01-5164. https://doi.org/10.4271/2023-01-5164

4. Ujah C.O., Von Kallon D.V. Trends in aluminium matrix composite development. Crystals. 2022;12(10):1357. https://doi.org/10.3390/cryst12101357

5. Mussatto A., Ahad I.U.I., Mousavian R.T., Delaure Y., Brabazon D. Advanced production routes for metal matrix composites. Engineering Reports. 2021;3(5):e12330. https://doi.org/10.1002/eng2.12330

6. Garg P., Jamwal A., Kumar D., Sadasivuni K.K., Hussain C.M., Gupta P. Advance research progresses in aluminium matrix composites: Manufacturing & applications. Journal of Materials Research and Technology. 2019;8(5): 4924–4939. https://doi.org/10.1016/j.jmrt.2019.06.028

7. Kar A., Sharma A., Kumar S. A critical review on recent advancements in aluminium-based metal matrix composites. Crystals. 2024;14:412. https://doi.org/10.3390/cryst14050412

8. Kurganova Yu.A., Kolmakov A.G. Structural metal matrix composite materials. Moscow: Publ. MSTU, 2015. 144 p. (In Russ.).

9. Parikh V.K., Patel V., Pandya D.P., Andersson J. Current status on manufacturing routes to produce metal matrix composites: State-of-the-art. Heliyon. 2023;9(2):e13558. https://doi.org/10.1016/j.heliyon.2023.e13558

10. Ruzic J., Simić M., Stoimenov N., Božić D., Stašić J. Innovative processing routes in manufacturing of metal matrix composite materials. Metallurgical and Materials Engineering. 2021;27(1):1–13. https://doi.org/10.30544/629

11. Nayak K.C., Rane K.K., Date P.P., Srivatsan T.S. Synthesis of an aluminum alloy metal matrix composite using powder metallurgy: Role of sintering parameters. Applied Sciences. 2022;12:8843. https://doi.org/10.3390/app12178843

12. Khazin M.L., Apakashev R.A., Davydov S.Ya. Obtaining aluminum-matrix composite materials particulate-reinforced with ceramic particles. Refractories and Industrial Ceramics. 2022;63(3):291–296. https://doi.org/10.1007/s11148-022-00719-4

13. Purohit R., Qureshi M., Jain A. Forming behaviour of aluminium matrix nano Al2O3 composites for automotive applications. Advances in Materials and Processing Technologies. 2020;6(6):272–283. https://doi.org/10.1080/2374068X.2020.1731665

14. Vinod B., Ramanathan S., Ananthi V., Selvakumar N. Fabrication and characterization of organic and in-organic reinforced A356 aluminium matrix hybrid composite by improved double-stir casting. Silicon. 2019;11:817–829. https://doi.org/10.1007/s12633-018-9881-5

15. Ujah C., Popoola A., Popoola O., Aigbodion V.S. Influence of CNTs addition on the mechanical, microstructural, and corrosion properties of Al alloy using spark plasma sintering technique. International Journal of Advanced Manufacturing Technology. 2020; 106:2961–2969. https://doi.org/10.1007/s00170-019-04699-7

16. Singh N., Belokar R.M. Tribological behavior of aluminum and magnesium-based hybrid metal matrix composites: A state-of-art review. Materials Today: Proceedings. 2021;44(1):460–466. https://doi.org/10.1016/j.matpr.2020.09.757

17. Kumar N., Das A. Ecofriendly energy efficient welding of aluminium matrix composites for aerospace applications: A state of art review. Materials Today: Proceedings. 2020;26(2):1666–1675. https://doi.org/10.1016/j.matpr.2020.02.352

18. Mohanavel V., Ravichandra, M., Kumar S.S. Tribological and mechanical properties of zirconium di-boride (ZrB2) particles reinforced aluminium matrix composites. Materials Today: Proceedings. 2020;21(1):862–864. https://doi.org/10.1016/j.matpr.2019.07.603

19. Talalaeva G.V., Paznikova S.N. Modern composite materials: prospects and risks of their use in the field of integrated security and civil defense. Tekhnologii grazhdanskoi bezopasnosti. 2023;1(75):107–114. (In Russ.).

20. Khan M., Zulfaqar M., Ali F., Subhani T. Hybrid aluminium matrix composites containing boron carbide and quasicrystals: Manufacturing and characterisation. Materials Science and Technology. 2017;33(16):1955–1963. https://doi.org/10.1080/02670836.2017.1342017

21. Ibrahim T.K., Yawas D.S., Thaddaeus J., Danasabe B, lliyasu I., Adebisi A.A., Ahmadu T.O. Development, modelling and optimization of process parameters on the tensile strength of aluminum, reinforced with pumice and carbonated coal hybrid composites for brake disc application. Scietific Reports. 2024;14:16999. https://doi.org/10.1038/s41598-024-67476-x

22. Seputra Y.E.A., Soegijono B. Engineering of aluminium matrix composite (AMC) reinforcement organoclay based on hotpress method using adaptive neuro-fuzzy inference system (ANFIS). IOP Conference Series: Materials Science and Engineering. 2019;509(1):012156. https://doi.org/10.1088/1757-899X/509/1/012156

23. Ağaoğullari D., Gökçe H., Genç A., Duman İ., Öveçoğlu M.L. Characterization of mechanically alloyed and sintered ZrC particulate reinforced Al matrix composites. In: Proc. of 19th International Conference on Metallurgy and Materials (METAL 2010). TANGER Ltd. Metal, 2010. P. 702–708.

24. Cug H., Zengin O. Investigation of microstructural and mechanical properties of zirconium carbide reinforced aluminum matrix nanocomposites. Acta Physica Polonica Series A. 2019;135(5):870–872. https://doi.org/10.12693/APhysPolA.135.870

25. Sundarrajan S., Satish Kumar T., Suganya Priyadharshini G. Production and characterization of Al6061/zirconium carbide surface composites. International Journal of Materials Research. 2020;111(8):639–644. https://doi.org/10.3139/146.111926

About the Authors

M. L. KhazinRussian Federation

Mark L. Khazin – Dr. Sci. (Eng.), Professor, Department of Mining Equipment Operation

30 Kuibysheva Str., Ekaterinburg 620144, Russia

R. A. Apakashev

Russian Federation

Rafail A. Apakashev – Dr. Sci. (Chem.), Professor, Department of Chemistry

30 Kuibysheva Str., Ekaterinburg 620144, Russia

V. E. Adas

Russian Federation

Vitalii E. Adas – Senior Lecturer, Department of Mining Equipment Operation

30 Kuibysheva Str., Ekaterinburg 620144, Russia

Review

For citations:

Khazin M.L., Apakashev R.A., Adas V.E. Structure and properties of an aluminum-matrix composite reinforced with zirconium carbide particles. Powder Metallurgy аnd Functional Coatings (Izvestiya Vuzov. Poroshkovaya Metallurgiya i Funktsional'nye Pokrytiya). 2025;19(5):51-59. https://doi.org/10.17073/1997-308X-2025-5-51-59