Scroll to:

Fabrication of (Ti-Al-Si)/(Ti-C)/Ti – layered alloy by SHS pressing

https://doi.org/10.17073/1997-308X-2023-1-21-27

Abstract

A metal-carbide-intermetallic material based on combustion products of the layer system (Ti-Al-Si)/(Ti-C)/Ti was for the first time obtained with the help of self-propagating high-temperature synthesis (SHS) combined with pressing. Exothermic synthesis from elementary powders was carried out at a pressure of 10 MPa, and pressing of the hot synthesis product was carried out at a pressure of 100 MPa. It has been shown that SHS pressing contributes to the formation of permanent joints of «metal/carbide/intermetallic» layers. The main features of microstructure formation, phase composition, and strength properties of transition zones at the boundary between reacting SHS compositions, Ti-C and Ti-Al-Si and Ti-metal substrate are investigated. It is shown that during SHS reaction, a homogeneous microstructure of Ti-C and Ti-Al-Si layers with an insignificant content of cracks and pores is formed. The thickness of the transition zone between the layers was at least 15 µm. The main phase formed in the combustion product of Ti-Al-Si layer is, according to the results of X-ray phase analysis, triple phase Ti20Al3Si9, the content of which, calculated by the Rietveld method, was at least 87 wt. %. In addition, the combustion product contains a secondary phase of Ti3Al in the amount of 13 wt. %. The energy dispersion analysis revealed that diffusion of aluminium through the titanium carbide layer into the titanium substrate to a depth of approx. 30 µm is observed. Microhardness value of the combustion product of Ti-Al-Si layer was about 10 GPa. The rectilinear nature of crack propagation in the synthesized combustion product of Ti-Al-Si layer, as well as the Palmquist crack resistance coefficient varying within 5.1-5.7 MPa·m1/2, indicate the fragility of the material.

For citations:

Lazarev P.A., Busurina M.L., Gryadunov A.N., Sytschev A.E., Belikova A.F. Fabrication of (Ti-Al-Si)/(Ti-C)/Ti – layered alloy by SHS pressing. Powder Metallurgy аnd Functional Coatings (Izvestiya Vuzov. Poroshkovaya Metallurgiya i Funktsional'nye Pokrytiya). 2023;17(1):21-27. https://doi.org/10.17073/1997-308X-2023-1-21-27

Introduction

Obtaining layered systems and permanent joints of various metal-intermetallic materials constitutes a significant task for modern industry, particularly for aerospace applications, taking into account the unique combination of physical and mechanical characteristics of metal-intermetallic layered composites [1]. Material microstructure development, oriented towards a specific set of structural and functional characteristics, represents an urgent task in materials science. Ti–Al titanium aluminides can be distinguished among a variety of intermetallic compounds, which need to increase their temperature resistance to oxidation and deformation [2–4]. Titanium-based alloys with other light elements (Mg, Si etc.) appear to be highly promising for high-temperature applications in a variety of industries, particularly for use as protective coatings. Silicon appears to be a compelling choice for a reinforcing component (Ti5Si3 ) in a TiAl-based composite and also positively affects the resistance of titanium and its alloys to high-temperature oxidation [5; 6].

Since the well-known methods for producing the required materials (hot isostatic pressing [7] and spark plasma sintering [8]) are costly and technically demanding, it is essential to find new, technologically simplified methods for their production. Self-propagating high-temperature synthesis (SHS) may be a promising way of solving the problem of obtaining metal-intermetallic layered materials [9]. During the SHS process, a large amount of heat released can be used not only for further processing of the material or formation of its structure, but also as a source of additional heat for joining (welding, repairing) heterogeneous materials and applying coatings [10; 11]. For instance, Ti–Al–Si alloys were produced by SHS in work [12] upon the interaction of titanium, silicon, and AlSi30 alloy followed by the addition of alloying elements. A method for the production of Ti–Al–Si alloys with an aluminum content ranging from 8 to 20 %1 and a silicon content of 10–20 % has been elaborated in works [13–15]. Combining the SHS method and pressing may be used to produce layered and graded carbide-hardened materials, as well as permanent joints of heterogeneous materials and protective coatings. The SHS-pressing method was used to obtain NiAl–Ni layer compositions [16] and multilayer systems “hard alloy–intermetallic–metal” [17].

In this paper, the features of the formation of microstructure and strength properties of transition zones at the boundary between reacting SHS compounds and Ti-substrate in a layer system (Ti–Al–Si)/(Ti–C)/Ti have been investigated.

Experimental procedures

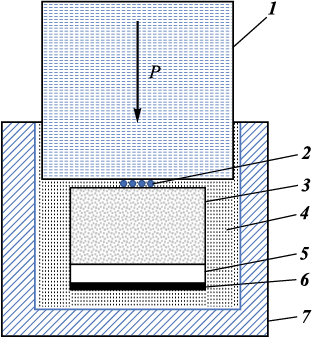

The following metal powders were used in the experiment: Si (semiconductor silicon, solar-grade, ~100 µm, at least 99 %), Ti (PTM, <100 µm, 99.2 %), and Al (ASD-4, ~10 µm, 99.20 %) to obtain a powder reaction mixture of 74.1Ti–6.3Al–19.6Si (%); incendiary mixture Ti/C (black) (50/50 %); titanium foil (Ti) of 200 µm thick. The mass ratio of layers 1-layer/2-layer/Ti-substrate was approximately ~90/8/2 %. Composition of the reaction mixture based on Ti–Al–Si was chosen to obtain the phase Ti20Al3Si9 . The initial powder blank of the 1st layer was obtained by dry mixing in a mortar, followed by pressing of cylindrical samples 30 mm in diameter and 16 mm in height with a relative density of 0.6. The compressed samples were placed in a reaction compression mold (Fig. 1), pre-mounted on a Ti substrate.

Fig. 1. Scheme of experiments on SHS pressing |

To obtain a nonporous material, SHS pressing technique described in [18; 19] has been used, while exothermic synthesis was carried out at a pressure of 10 MPa, and pressing of the synthesis product was carried out at a pressure of 100 MPa. The exposure time under load was 3 s.

The microstructure of the synthesized alloy was studied using an “Zeiss Ultra plus 55” field emission scanning electron microscope. X-ray phase analysis (XRD) was performed on a DRON-3 diffractometer using CuKα radiation. Microhardness (Hµ ) was measured on a PMT-3 hardness tester using the Vickers method (indentation of a tetrahedral diamond pyramid with a load of 100 g). Crack formation was studied by the method of indentation by the Vickers diamond pyramid HV at a higher load of up to 30 kg.

Results and discussion

Preliminary thermodynamic calculations performed in the software “Thermo” 2 clearly revealed that the largest thermal effect is observed in the layer based on the Ti–C system for which the adiabatic combustion temperature was 2617 °C and the enthalpy of formation was 176 kJ/ mol. During the combustion of Ti–C reaction composition, the melting of the surface layer of the titanium substrate ( \(t_{{\rm{Ti}}}^{{\rm{melt}}}\) = 1670 °C) and the formation of the Ti/TiC transition zone is most likely to occur. Adiabatic combustion temperature of Ti–C is much higher than combustion temperature of Ti–Al–Si layer, equal to 1259 °C [15] which also affects the diffusion interaction and formation of a transition zone between Ti–C and Ti–Al–Si layers and provides a strong interpase connection between the Ti-substrate and the Ti–C carbide layer.

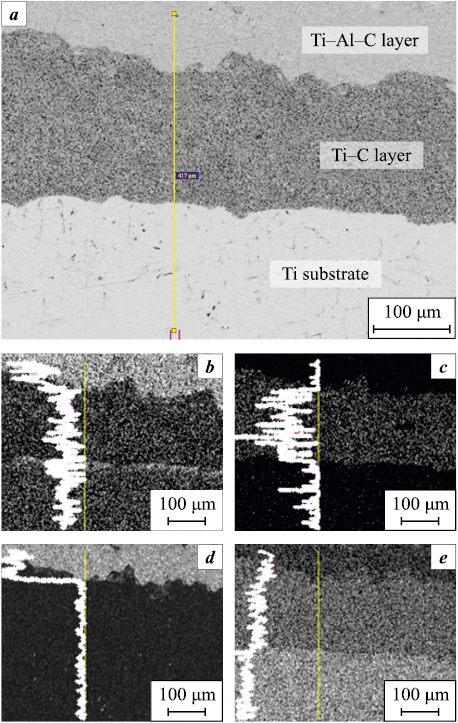

Figure 2 represents the microstructure and element distribution map of Ti, Al, Si and C in the synthesised alloy. A firm contact between the layers with the absence of any defects (pores, cracks) has been formed. This indicates a high quality of diffusion interaction of the elements between the layers.

Fig. 2. Photo of the microstructure (а) and element |

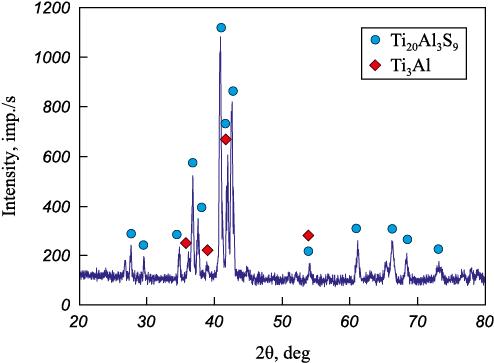

As shown by XRD (Fig. 3), the 1st layer conforms to an alloy based on the main phase Ti20Al3Si9 (PDF 01-079-2701) with a hexagonal close-packed (HCP) lattice; furthermore, there is a secondary ordered phase Ti3Al with a superstructure D019 (PDF 52-859), which exhibits a HCP latitude (spatial group P63/mmc). The content of the main phase Ti20Al3Si9 (calculated by the Rietveld method) was 87 %, the phase Ti3Al – 13 %. According to the data obtained by energy-dispersive analysis (EDA), the 2nd layer conforms to the phase TiC0.66 (cubic structure Fm3m), and the 3rd layer conforms to titanium in a substrate made of titanium foil. The transition zones between the layers do not exceed 10–15 µm.

Fig. 3. X-ray data of a synthesized alloy based |

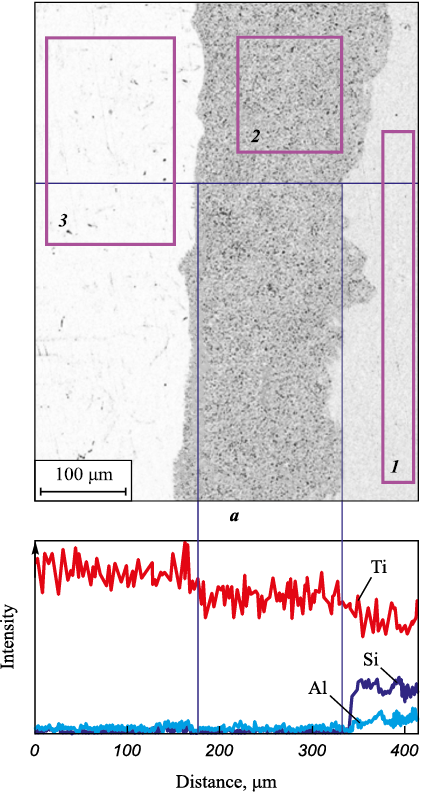

According to the concentration profile of the element distribution between the layers (Fig. 4) a slight increase of aluminium concentration in the boundary area between Ti/TiC layers can be observed due to the melting of the titanium foil caused by heat release during reaction in the Ti–C layer and diffusion of aluminium into the titanium substrate through the Ti–C layer. Upon that, the depth of Al diffusion into the Ti substrate is rather shallow ~30 µm. Silicon concentration during transition from the Ti–Al–Si layer to Ti–C drops sharply and remains at zero values in the 2nd and 3rd layers.

Fig. 4. Concentration profile of element distribution |

Microhardness (Hµ ) of each of the layers of the synthesized gradient material is presented in Table. The highest Hµ value (~12.3 GPa) corresponds to a Ti–C-based layer, the lowest is for a titanium substrate (4.1 GPa). Microhardness of Ti–Al–Si layer is ~10.1 GPa.

Microhardness values in layers of the synthesized material

| |||||||||||||||||||||

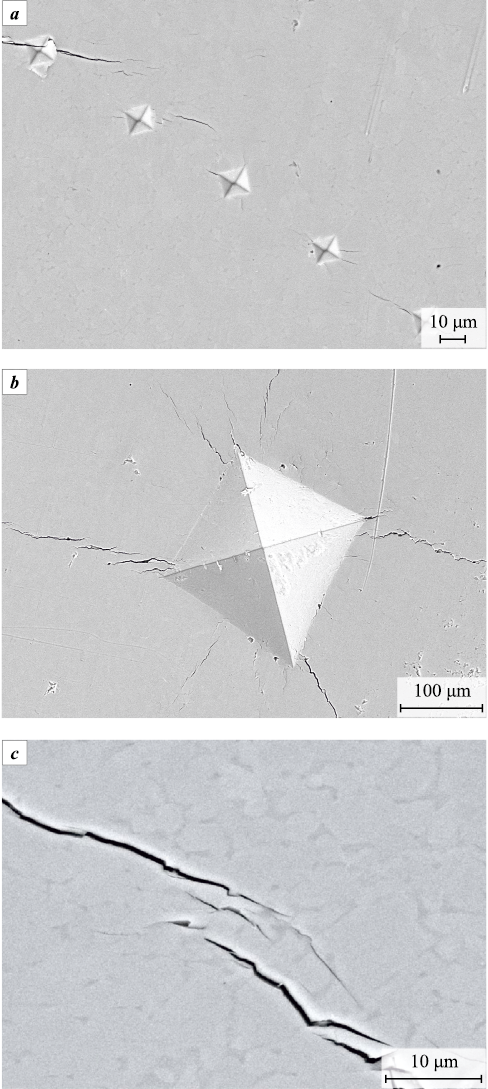

When an indenter is inserted at a load of more than 30 kg into a Ti–Al–Si-based layer, radial cracks are formed in the corners of the Vickers pyramid imprints in the area of maximum tension stresses (Fig. 5, a, b). The formation of main concomitant cracks and their branching, as well as the fusion of cracks with micro-heterogeneities and structural defects are observed (Fig. 5, c). One of the reasons for this is that the micropores affect the crack propagation process. The rectilinear nature of crack propagation indicates a high fragility of the material. It is noteworthy that the cracks propagate both through and around the grains (Fig. 5, c). Calculated by the Palmquist method [20] for a Ti–Al–Si-based layer, the crack resistance coefficient is K1c = 5.1÷5.7 MPa·m1/2. The measurements were taken at an indenter load of 100 g using the formula

\[{K_{1c}} = 0.0028\sqrt {HV} \sqrt P {c^{ - 1}},\]

where P – indentation load, c – total length of the crack from the indenter, mm.

Fig. 5. Micrographics of indentation after measuring |

The following results can be given to compare the resulting value of K1с . According to work [21], the crack resistance coefficient of Ti–Al–Si-based alloys can reach values from 0.7 to 1.7 MPa·m1/2, while Ti5Si3 silicide has K1с = 7 MPa·m1/2 [22]. It is noted in work [23] that materials based on Ti–Al3Ti with a volume fraction of Al3Ti phase equal to 86, 80, and 65 % are characterized by high crack resistance values at the level of 15, 23, and 29 MPa·m1/2, respectively. The measurement results of K1с depend on the size and direction of movement of cracks, pores, interphase transformations, and the magnitude of loads on the material.

Conclusion

A metal-carbide-intermetallic layer material based on (Ti–Al–Si)/(Ti–C)/Ti was synthesized by SHS pressing. The heat released as a result of SHS reactions in the layers and the subsequent pressing of the hot product ensured the required diffusion through the boundaries (Ti–Al–Si)/(Ti–C) and (Ti–C)/Ti and resulted in the formation of a solid permanent joint between the layers with a transition zone thickness between them about 10÷15 μm. Combustion product of Ti–Al–Si layer exhibits two phases: triple phase Ti20Al3Si9 and Ti3Al with a content of 87 and 13 wt. %, respectively. The microhardness of the synthesized combustion product of Ti–Al–Si layer was ~10.1 GPa, crack resistance coefficient K1с = 5.1÷5.7 MPa·m1/2. The obtained results can be used in the development of methods for applying protective coatings/layers to the surface of titanium products.

References

1. Vecchio K.S. Synthetic multifunctional metallic-intermetallic laminate composites. JOM. 2005;57(3):25-31. https://doi.org/10.1007/s11837-005-0229-4

2. Patselov A., Greenberg B., Gladkovskii S., Lavrikov R., Borodin E. Layered metal-intermetallic composites in Ti-Al system: strength under static and dynamic load. AASRI Procedia. 2012;3:107-112. https://doi.org/10.1016/j.aasri.2012.11.019

3. Price R.D., Jiang F., Kulin R.M., Vecchio K.S. Effects of ductile phase volume fraction on the mechanical properties of Ti-TiAl3 metal-intermetallic laminate (MIL) composites. Materials Science and Engineering: A. 2011; 528(7-8):3134-3146. https://doi.org/10.1016/j.msea.2010.12.087

4. Lasalmonie A. Intermetallics: Why is it so difficult to introduce them in gas turbine engines? Intermetallics. 2006;14(10-11);1123-1129. https://doi.org/10.1016/j.intermet.2006.01.064

5. Xiong H.-P., Mao W., Xie Y.-H., Cheng Y.-Y., Li X.-H. Formation of silicide coatings on the surface of a TiAl-based alloy and improvement in oxidation resistance. Materials Science and Engineering A. 2005;391(1-2):10-18. https://doi.org/10.1016/j.msea.2004.05.026

6. Teng S., Liang W., Li Z., Ma X.J. Improvement of high-temperature oxidation resistance of TiAl-based alloy by sol-gel method. Journal of Alloys and Compounds. 2008;464(1-2): 452-456. https://doi.org/10.1016/j.jallcom.2007.10.017

7. Gao N.F., Miyamoto Y., Zhang D. Dense Ti3SiC2 prepared by reactive HIP. Journal of Materials Science. 1999;34(18):4385-4392. https://doi.org/10.1023/A:1004664500254

8. Konoplyuk S., Abe T., Uchimoto T., Takagi T. Ti3SiC2/TiC composites prepared by PDS. Journal of Materials Science. 2005;40(13):3409-3413. https://doi.org/10.1007/s10853-005-0417-1

9. Feng J.C., Cao J., Li Z.R. Microstructure evolution and reaction mechanism during reactive joining of TiAl intermetallic to TiC cermet using Ti-Al-C-Ni interlayer. Journal of Alloys and Compounds. 2007;436(1-2):298-302. https://doi.org/10.1016/j.jallcom.2006.07.040

10. Sytschev A.E., Vadchenko S.G., Boyarchenko O.D., Vrel D., Sachkova N.V. SHS joining of intermetallics with metallic substrates. International Journal of Self-Propagating High-Temperature Synthesis. 2011;20(3):185-190. https://doi.org/10.3103/S1061386211030149

11. Pascal C., Marin-Ayral R.M., Tedenac J.C., Merlet C. Combustion synthesis: a new route for repair of gas turbine components - principles and metallurgical structure in the NiAl/RBD61/superalloy junction. Materials Science and Engineering: A. 2003;341(1-2):144-151. https://doi.org/10.1016/S0921-5093(02)00205-8

12. Novak P., Knz J., Prusa F., Kubasek J., Marek I., Michal-cova A., Voderova M., Vojtech D. Structure and properties of Ti-Al-Si-X alloys produced by SHS method. Interme-tallics. 2013;39:11-19. https://doi.org/10.1016/j.intermet.2013.03.009

13. Novak P, Michalcova A., Serak J., Vojtech D., Fabian T., Randakova S., Prusa F., Knotek V., Novak M. Preparation of Ti-Al-Si alloys by reactive sintering. Journal of Alloys and Compounds. 2009;470(1-2):123-126. https://doi.org/10.1016/j.jallcom.2008.02.046

14. Novak P., Popela T., Kubasek J., Serak J., Vojtech D., Michalcova A. Effect of reactive sintering conditions on microstructure of in situ titanium aluminide and silicide composites. Powder Metallurgy. 2011;54(1):50-55. https://doi.org/10.1179/174329009X409651

15. Lazarev P.A., Sytchev A.E., Boyarchenko O.D., Abor-kin A.V. Self-propagating high-temperature synthesis in the Ti-Al-Si system. Inorga nic Materials. 2021;57(11): 1201-1207. https://doi.org/10.1134/s002016852111008x

16. Sytschev A.E., Vrel D., Boyarchenko O.D., Vadchen-ko S.G., Sachkova N.V. Load-assisted SHS joining of NiAl to Ni. International Journal of Self-Propagating High-Temperature Synthesis. 2013;22(1):52-55. https://doi.org/10.3103/S1061386213010111

17. Sytschev A.E., Bondarchuk Yu.V., Pityulin A.N. SHS compunction of multilayer solid alloy/metal materials. International Journal of Self-Propagating High-Temperature Synthesis. 1993;2(1):75-83.

18. Питюлин А.Н. Силовое компактирование в СВС-процессах. В сб.: Самораспространяющийся высокотемпературный синтез: теория и практика. Под ред. А.Е. Сычева. Черноголовка: Территория, 2001. С. 333-353.

19. Shcherbakov V.A., Gryadunov A.N., Alymov M.I. Synthesis and characteristics of the B4C-ZrB2 composites. Letters on Mate rials. 2017;7(4):398-401. https://doi.org/10.22226/2410-3535-2017-4-398-401

20. Palmqvist S. A method to determine the toughness of brittle materials, especially hard materials. Jernkontorets Ann. 1957;141:303-307.

21. Knaislova A., Novak P., Cabibbo M., Prusa F., Paoletti C., Jaworska L., Vojtech D. Combination of reaction synthesis and Spark Plasma Sintering in production of Ti-Al-Si alloys. Journal of Alloys and Compounds. 2018; 752:317-326. https://doi.org/10.1016/j.jallcom.2018.04.187

22. Grigorenko S.G., Grigorenko G.M., Zadorozhnyuk O.M. Intermetallics of titanium. Peculiar features, properties, application (Review). Electrometallurgy Today (Sovre-mennaya Elektrometal lurgiya). 2017;(3):51-58. https://doi.org/10.15407/sem2017.03.08

23. Rohatgi A., Harach D.J., Vecchio K.S., Harvey K.P. Resistance-curve and fracture behavior of Ti-Al3Ti metallic-intermetallic laminate (MIL) composite. Acta Materialia. 2003;51(10):2933-2957. https://doi.org/10.1016/S1359-6454(03)00108-3

24. Trefilov V.I., Milman Yu.V., Gridneva I.V. Mechanical properties of covalent crystals. Neorganicheskie materialy. 1984;20(6):958-966. (In Russ.).

25. Haiyang N., Shiwei N., Oganov A.R. Simple and accurate model of fracture toughness of solids. Journal of Applied Physics. 2019;125(6):065105. https://doi.org/10.1063/1.5066311

About the Authors

P. A. LazarevRussian Federation

Pavel A. Lazarev - Junior Researcher of the Laboratory of physical materials science ISMAN.

8 Akademican Osip'yan Str., Chernogolovka, Moscow region 142432

M. L. Busurina

Russian Federation

Maria L. Busurina - Cand. Sci. (Eng.), Junior Researcher of the Laboratory of physical materials science of ISMAN.

8 Akademican Osip'yan Str., Chernogolovka, Moscow region 142432

A. N. Gryadunov

Russian Federation

Aleksander N. Gryadunov - Cand. Sci. (Phys.-Math.), Senior Researcher of the Laboratory of energy stimulation of physico-chemical processes of ISMAN.

8 Akademican Osip'yan Str., Chernogolovka, Moscow region 142432

A. E. Sytschev

Russian Federation

Aleksander E. Sytschev - Cand. Sci. (Eng.), Leading Researcher, Head of the Laboratory of physical materials science of ISMAN.

8 Akademican Osip'yan Str., Chernogolovka, Moscow region 142432

A. F. Belikova

Russian Federation

Alevtina F. Belikova - Senior Researcher of the Laboratory of energy stimulation of physico-chemical processes of ISMAN.

8 Akademican Osip'yan Str., Chernogolovka, Moscow region 142432

Review

For citations:

Lazarev P.A., Busurina M.L., Gryadunov A.N., Sytschev A.E., Belikova A.F. Fabrication of (Ti-Al-Si)/(Ti-C)/Ti – layered alloy by SHS pressing. Powder Metallurgy аnd Functional Coatings (Izvestiya Vuzov. Poroshkovaya Metallurgiya i Funktsional'nye Pokrytiya). 2023;17(1):21-27. https://doi.org/10.17073/1997-308X-2023-1-21-27