Scroll to:

Additive manufacturing of continuous fibre reinforced polymer composites using industrial robots: A review

https://doi.org/10.17073/1997-308X-2024-1-20-30

Abstract

In recent years, the mechanical engineering sector has undergone significant changes due to the creation and expanding application of new technologies and materials capable of radically improving the quality of manufactured products, the entire structure and production conditions. Such technologies include additive manufacturing capable of creating products from advanced materials such as continuous reinforced polymer composites. Furthermore, the integration of additive manufacturing with industrial robots offers new opportunities to create spatially reinforced composites with a directed internal structure, obtained by the orderly arrangement of continuous fibres. This review analyzes the currently available technologies for 3D printing spatially reinforced polymer composites with the addition of continuous fibers using industrial robots. The review presents the main advanced companies supplying off-the-shelf commercial systems and presents the successful experience of using these systems in the production of reinforced parts

Keywords

For citations:

Sotov A.V., Zaytsev A.I., Abdrahmanova A.E., Popovich A.A. Additive manufacturing of continuous fibre reinforced polymer composites using industrial robots: A review. Powder Metallurgy аnd Functional Coatings (Izvestiya Vuzov. Poroshkovaya Metallurgiya i Funktsional'nye Pokrytiya). 2024;18(1):20-30. https://doi.org/10.17073/1997-308X-2024-1-20-30

Introduction

Additive manufacturing (AM) constitutes a swiftly expanding market, attaining significance in the shift towards advanced industrial production. Previously, emphasis predominantly centered on the 3D printing of metal [1–5] and polymer materials [6–9]. However, there exists a burgeoning interest in more intricate applications and innovative material types, commonly referred to as modern or advanced materials. These materials hold potential for implementation across five distinct categories [10]: technical ceramics (oxides, carbides) [11; 12], polymers (such as the PAEK family encompassing PEEK and PEKK) [13; 14], metals (refractory metals like tungsten and molybdenum) [15; 16], 4D materials (materials exhibiting shape memory) [17–20], and composites, specifically polymer composite materials (PCMs) featuring continuous fibers [21; 22].

Presently, traditional PCM production, primarily conducted using woven fiber sheets and thermosetting resins, stands as one of the labor-intensive and costly manufacturing processes [23]. Nonetheless, composites persist as one of the swiftest growing and rapidly evolving industrial segments in the global market. The anticipation is that AM technologies will assume a pivotal role in this evolution, given the array of emerging commercially available technologies and processes.

Recently, VoxelMatters (UK), a company specializing in market research and analytics within the AM industry, unveiled a comprehensive map showcasing technologies and existing companies offering commercial systems for implementing 3D printing processes [24]. This map provides users with insights into the spectrum of extant 3D printing technologies and the evolving landscape of AM across various materials, notably polymer composites. Employees at VoxelMatters [25] highlight that among all material families, polymer composites reinforced with fibers-specifically continuous fibers-possess distinctive properties and advantages. They underscore that leveraging 3D printing technology will augment the utilization of these materials, enabling more efficient, cost-effective, and expedited manufacturing of parts with a unique combination of final functional properties.

There are currently companies offering desktop systems designed for 3D printing of continuous fiber PCM. However, utilizing these 3D printers for PCM manufacturing presents several disadvantages, the primary one being the limitation of fiber placement solely within the plane of the construction platform [26]. This limitation significantly impacts product design and creation since the highest mechanical properties are attained when load application aligns with the direction of reinforcement. This drawback restricts the production of a broad range of parts that experience loads not confined to the same plane. To address these limitations and other issues inherent in desktop 3D printers, specialized equipment is being developed based on industrial robotic manipulators. This approach introduces fresh possibilities and sets new benchmarks for PCM manufacturing. Key advantages include a larger working area facilitated by robotic arms compared to desktop 3D printers, along with the capability to fabricate spatially reinforced polymer composite products. This is made feasible due to the increased degrees of freedom afforded by robot manipulators. Detailed insights into the intricacies of producing such products and materials, encompassing aspects like tool path planning, kinematics, robot collision avoidance, and technological constraints encountered during the printing process, are extensively described in papers.

This review focuses on examining the present-day technologies for 3D printing of spatially reinforced PCM with added continuous fibers through industrial robotic manipulators. It highlights leading advanced companies providing readily available commercial systems and assesses the successful utilization of these systems in producing reinforced parts.

Existing technology of 3D printing

for continuously reinforced PCM

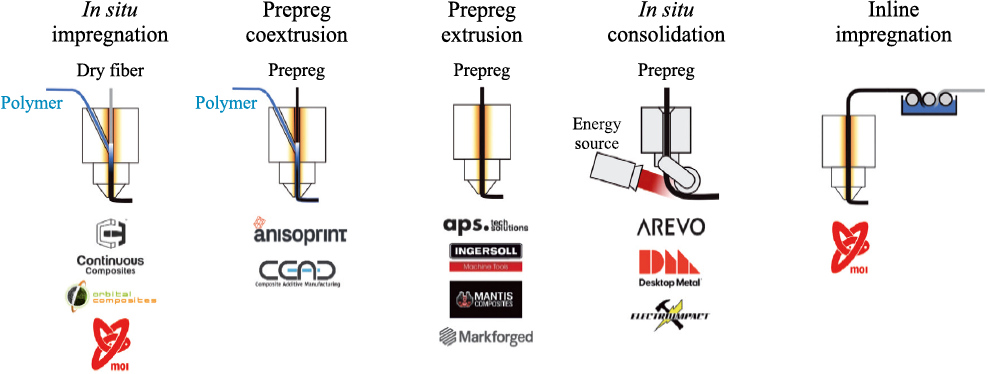

The evolution of 3D printing technologies for continuously reinforced PCM has been steady yet notably swift, resulting in the emergence of various terms and methodologies. Researchers at the Technical University of Munich have endeavored to establish a conceptual framework for standardizing 3D printing processes involving continuously reinforced PCM. The intricacy of this endeavor largely stems from the idiosyncrasies inherent in the execution of printing processes adopted by different companies [29]. Nevertheless, contemporary trends indicate a movement toward categorizing these processes based on the methodologies used for supplying reinforcing and matrix materials to the printing head and their deposition during the part-building process. Fig. 1 provides an overview of the current implementation schemes and identifies companies offering commercial systems for PCM 3D printing incorporating continuous fibers.

Fig. 1. Processes сlassification and basic 3D printing companies |

It is evident that there are presently five distinct approaches employed in the realization of the robotic 3D printing process for continuously reinforced PCMs using commercially available equipment. Below, a summary of the primary accomplishments attained thus far for each of these schemes is outlined.

1. In situ impregnation

The core principle of this technology involves the in situ impregnation of continuous dry fiber within the extrusion head of the printer using specialized thermosetting or thermoplastic polymer materials. This is followed by material extrusion through a nozzle and subsequent curing. Among the key companies employing the in situ impregnation process via industrial robotic manipulators are Continuous Composites (USA) [33], Orbital Composites (USA) [34], and Moi Composites (Italy) [35]. Predominantly, carbon and basalt fibers serve as the primary reinforcing materials, while less commonly used options include glass fiber and natural fibers.

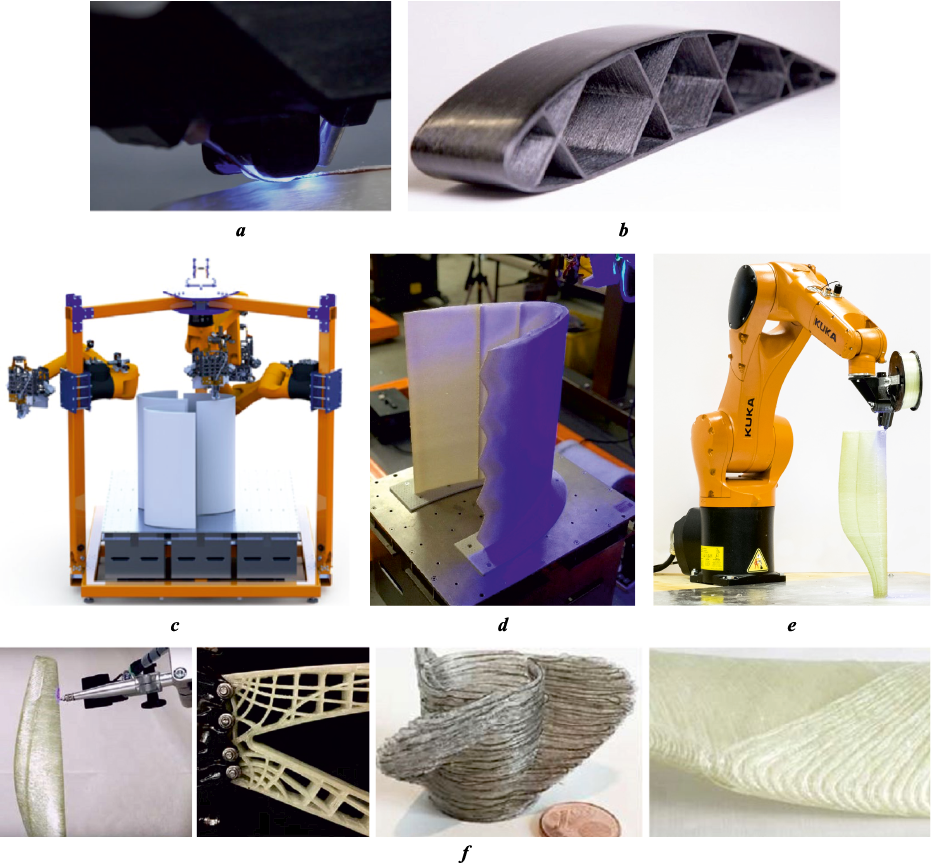

Continuous Composites, established in 2015, has pioneered a patented 3D printing technology termed Continuous Fiber 3D Printing (CF3D). This technique involves the in situ impregnation of continuous dry fiber with a specialized fast-curing thermoset resin. As the material is extruded through the nozzle, it undergoes instant curing facilitated by a UV light source. According to the company’s reports [36], the utilization of an industrial robot enables material deposition in any direction, optimizing the orientation of reinforcing fibers based on the specific design requirements of the manufactured part. Continuous Composites’ patented CF3D technology can be employed with gantry robots or industrial robots, providing flexibility in manufacturing. Utilizing a 6-axis robot from Comau, the company has successfully fabricated intricate parts and components, including a carbon fiber aircraft wing spar element (Fig. 2, b).

Fig. 2. Examples of the use of 3D printing of PCM by various companies |

Continuous Composites employs both structural fibers (such as carbon, glass-filled, and Kevlar) and functional fibers (including optical and metallic fibers) as reinforcing materials. The choice of the matrix polymer material is predicated on mechanical properties, heat transfer characteristics, and environmental resilience, aligning with the operational requisites of the intended product.

The successful application of CF3D technology has extended to several university research laboratories [37–40]. In one study [40], the researchers showcased their investigations into the mechanical properties of PCMs manufactured using CF3D technology via the Comau industrial robotic arm. They examined samples fabricated from high-temperature thermosetting acrylic polymer GF-2, combined with high-strength carbon fiber T-1100 at a volume fraction of 41.5 %. The resulting samples exhibited a Young’s modulus of 122 GPa and a tensile strength of 1599 MPa, constituting 89 % (137 GPa) and 55 % (2926 MPa) of the theoretical values, respectively. The authors [40] underscored that these results are notably high within the realm of additive manufacturing, highlighting the promising potential of CF3D technology for manufacturing PCM parts.

Established in 2014, Orbital Composites initially carved its niche in 3D printing components tailored for space applications. Presently, the company is pioneering its proprietary 3D printing technology, entailing the in situ impregnation of continuous dry fiber with thermoplastic polymer material, subsequently compacted using a roller. The manufacturer currently offers three distinct types of 3D printers based on industrial robots: “Orbital e-” – a 6-axis robot geared towards educational and research endeavors, featuring a 1.2×1.2 m building platform capable of printing with high-temperature thermoplastics; “Orbital S” is an industrial-class robot with a unique manipulator movement system, enabling flexible attachment points. This facilitates the printing of large parts from multiple angles (Fig. 2, c); “Orbital F” is a container-type 3D printer for producing substantial composite structures of large dimensions.

The 3D printers developed by Orbital Composites possess the capability to heat the nozzle to temperatures surpassing 500 °C. This functionality enables printing with a wide spectrum of matrix materials, encompassing all prevailing low-temperature thermoplastics, in addition to high-temperature materials like PEEK, PEKK, and others.

Founded in 2018 at the Polytechnic University of Milan, Moi Composites has pioneered a 3D printing technology named Continuous Fiber Manufacturing (CFM) for continuously reinforced PCM. This technology involves impregnation utilizing epoxy resin, vinyl ester, and acrylic in conjunction with continuous glass, carbon, basalt, and other fibers (Fig. 2, e). Besides manufacturing 3D printers, the company produces 3D printing tool heads capable of integration with any 4-axis CNC machines, offering a flexible and scalable printing solution.

Moi Composites uses various thermosetting matrix materials, including epoxy resin, complex vinyl esters, and acrylic compositions. Continuous glass, carbon, and basalt fibers are employed as reinforcing components. The company is currently developing aramid and natural fibers. The company emphasises the use of acrylic materials for architectural details due to their transparency and the absence of a need for temperature during curing/post-curing. Materials based on complex vinyl esters are employed for marine components, whereas epoxy resin-based materials are favoured for the oil and gas as well as aerospace sectors.

2. Prepreg coextrusion

The underlying principle of this technology involves the coextrusion of a composite comprising preformed prepreg containing continuous fibers along with the addition of a thermoplastic element to facilitate adhesion to the matrix material. Key companies employing the prepreg coextrusion process utilizing robotic manipulators include Anisoprint (Luxembourg) [41] and CEAD (the Netherlands) [42].

Anisoprint, established in 2015, has innovated its own Continuous Fiber Coextrusion (CFC) 3D printing technology, employing two nozzles for matrix and reinforcing materials. The reinforcement nozzle comprises two distinct spools: one holding a tow of continuous fibers impregnated with thermoset, while the other contains a thermoplastic filament to enhance adhesion between the reinforcement and the matrix. Both are fed into a single extruder. This configuration of the process enables precise control over the volumetric ratio of fibers, while the utilization of a robot permits the establishment of intricate curvilinear trajectories during the 3D printing process (Fig. 3, a). The resulting manufactured parts constitute PCM structures comprising thermoset and thermoplastic polymers, interwoven with continuous fibers.

Fig. 3. Continuous fibre co-extrusion 3D printer based on the Kuka industrial robot |

Several low-temperature thermoplastics like PC, PLA, TPU, PETG, and PA can function effectively as matrix materials. Reinforcement can be achieved using prepregs containing continuous fibers of carbon, glass, aramid, basalt, and boron.

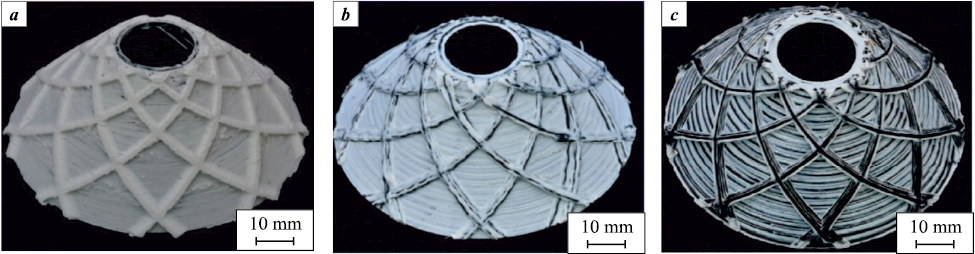

It is noteworthy that, the robotic prepreg coextrusion technology developed by Anisoprint has found extensive application across various industries [43–48]. In a study by the authors of [48], the focus was on investigating the 3D printing of conformal paths using industrial robots to create shell structures composed of PCM through coextrusion technology. The primary stages of the study involved the development of the production system, trajectory planning for conformal paths, and performance testing. The equipment utilized in the study comprised a Universal Robots UR10e robot equipped with a coextrusion head, along with an Anisoprint Composer A4 desktop 3D printer. During the research, three samples were fabricated (Fig. 4): the first sample was produced using 3-axis Composer A4 equipment; in the second sample, the conical part was also crafted on a 3D printer, while the stiffeners were generated by a robotic system; the third sample was manufactured using a conformal method with the robotic system. The part produced conformally using the robotic system exhibited a compressive strength and stiffness that were 258.6 % and 134.9 % higher, respectively, compared to parts created using a 3D printer with three degrees of freedom.

Fig. 4. Sample obtained on 3-axis equipment sample (a); |

The CEAD company, established in 2014, specializes in manufacturing large-scale robotic 3D printers and is known for developing its proprietary technology known as “Continuous Fiber Additive Manufacturing” (CFAM). This patented technology involves a print head that integrates continuous fibers with molten thermoplastic granules (Fig. 3, b, c).

3. Prepreg extrusion

The technology involves the extrusion of a composite prepreg impregnated with a thermoplastic polymer and embedded with continuous fibers. One notable commercial entity utilizing prepreg extrusion technology alongside industrial robotic manipulators is Ingersoll Machine Tools (USA) [49].

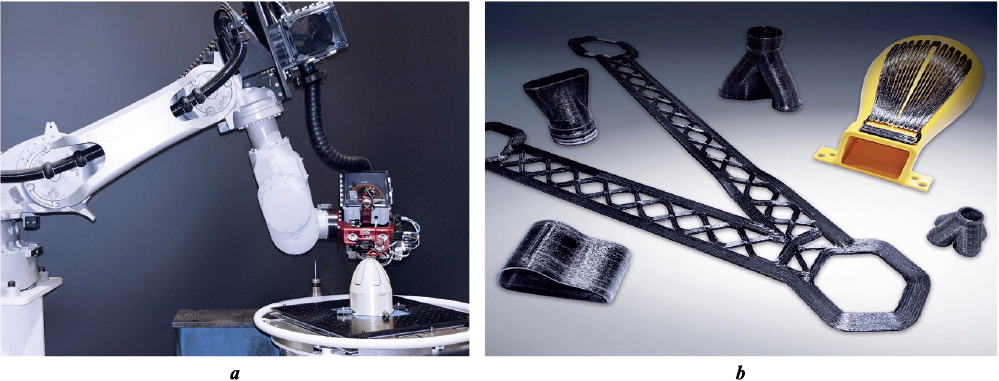

Founded in 1891, Ingersoll Machine Tools became a part of the Camozzi Group Corporation (Italy) in 2003. The company primarily specializes in the manufacturing of precision machines for metalworking, 3D printing, and automated fiber placement. Since 2015, the company has expanded its presence in the AM domain, currently offering five commercially available solutions, including MasterPrint Linear, MasterPrint 3X, and MasterPrint 5X. These machines are designed as large-scale 3D printers tailored for printing large-format PCM. Furthermore, the company presents two additional solutions grounded on industrial robotic arms specifically dedicated to 3D printing continuously reinforced PCM: “MasterPrint Robotic” and “MasterPrint Continuous Filament” (Fig. 5).

Fig. 5. 3D printing of PCM based on an industrial robot from “Ingersoll Machine Tools” (a) |

4. In situ consolidation

In situ consolidation technology, also referred to as automated fiber placement, entails the passage of fiber in prepreg form through a nozzle and subsequent heating with an added heat source directly at the outlet. In the realm of equipment manufacturers, there are companies providing desktop solutions, whereas the primary manufacturer utilizing industrial robots in this domain is the prominent company Electroimpact (USA) [50].

Established in 1986, Electroimpact employs robotic systems for 3D printing through Automated Fiber Placement (AFP) technology. The company’s developed technology merges the AFP method with FDM 3D printing [51]. This innovative approach involves printing a mold using the FDM method from a soluble polymer material. Continuous fibers are then laid in the form of a narrow ribbon on the mold’s surface by heating and sealing using a roller pre-impregnated with synthetic resin non-metallic fibers via the AFP method. After fiber placement, the polymer mold is dissolved. Electroimpact’s developments encompass SCRAM (Scalable Composite Robotic Additive Manufacturing), a 6-axis machine that combines AFP technology with FDM 3D printing [52].

Continuous fiber tape serves as the reinforcing material, pressed using a specialized roller during installation. The matrix materials primarily comprise thermoplastic polymers from the PAEK family (such as PEEK, PEKK, etc.), alongside nylon and other low-temperature thermoplastics like PA12, ABS, and others. Besides thermoplastics as matrix components, the printing technology also involves the utilization of water-soluble thermoplastics for producing temporary equipment. Fig. 6 showcases a 3D printer from the SCRAM series and a product exemplifying continuously reinforced PCM.

Fig. 6. SCRAM 3D printer in the process of applying fibres to a water-soluble tooling (a) |

5. Inline impregnation

Inline impregnation technology represents a hybrid process amalgamating the benefits of both conventional and additive manufacturing. In this method, composite fibers are prepared using conventional impregnation processes and subsequently applied to the build platform through a nozzle. As of now, “Moi Composites” (Italy) the company previously mentioned, stands as one of the representatives pioneering this technology.

Conclusions

This review presents an in-depth analysis of existing additive technologies and equipment utilized in the manufacturing of continuously reinforced PCM employing industrial robotic manipulators. It underscores the exceptional relevance and promise of this research domain, particularly in introducing spatially reinforced PCM imbued with distinctive properties for producing components in aviation, marine, nuclear, and other industrial sectors. The technologies discussed in the review are actively employed in the production of large-scale structural components, lightweight and durable aircraft parts, and composite equipment. Beyond structural applications, the utilization of robotic systems opens doors to creating shape-memory polymer 4D materials for intelligent structures. These structures offer controllable attributes, such as deployable hinge structures for solar panels and mirror antennas in space applications, reconfigurable antenna devices capable of altering directional patterns during operation, and intelligent metamaterial designs with adaptive dynamic characteristics for energy absorption and noise suppression across various frequency bands.

Significantly, the use of industrial robots offers increased degrees of freedom, enabling the fabrication of materials with an ordered arrangement of continuous fibers. This ability facilitates the formation of a directed internal structure in products, accounting for material property anisotropy. The creation of an ordered, directional structure via robotic 3D printing using continuous fibers achieves optimal reinforcing effects, aligning with the operational requirements of the final product. Despite the notable advancements, it’s evident from the literature analysis that the development of spatially reinforced PCMs using industrial robots remains an underexplored yet promising research area. The rapid evolution of the additive technology market and its distinctive capabilities in product shaping highlight the immense potential of this field. A key objective in advancing AM within this research domain is the standardization of manufacturing processes for continuously reinforced PCMs using industrial robotic manipulators, with the ultimate aim of deploying these technologies across diverse industries.

References

1. Sefene E.M. State-of-the-art of selective laser melting process: A comprehensive review. Journal of Manufacturing Systems. 2022;63:250–274. https://doi.org/10.1016/j.jmsy.2022.04.002

2. Yerubayeva A., Shehab E., Ali M.H. Recent advances and application of Selective Laser Melting (SLM) technology in the aerospace industry. In: AIP Conference Proceedings (25 April 2022). AIP Publishing LLC, 2022. Vol. 2470. No. 1. P. 030002. https://doi.org/10.1063/5.0080173

3. Sotov A.V., Agapovichev A.V., Smelov V.G., Kokareva V.V., Zenina M.V. Investigation of the Ni–Co–Cr alloy microstructure for the manufacturing of combustion chamber GTE by selective laser melting. International Journal of Advanced Manufacturing Technology. 2019;101: 3047–3053. https://doi.org/10.1007/s00170-018-3166-4

4. Ahmed N. Direct metal fabrication in rapid prototyping: A review. Journal of Manufacturing Processes. 2019;42:167–191. https://doi.org/10.1016/j.jmapro.2019.05.001

5. Svetlizky D., Das M., Zheng B., Vyatskikh A.L., Bose S., Bandyopadhyay A., Schoenung J.M., Lavernia E.J., Eliaz N. Directed energy deposition (DED) additive manufacturing: Physical characteristics, defects, challenges and applications. Materials Today. 2021;49:271–295. https://doi.org/10.1016/j.mattod.2021.03.020

6. Tan L.J., Zhu W., Zhou K. Recent progress on polymer materials for additive manufacturing. Advanced Functional Materials. 2020;30(43):2003062. https://doi.org/10.1002/adfm.202003062

7. Saleh Alghamdi S., John S., Roy Choudhury N., Dutta N.K. Additive manufacturing of polymer materials: Progress, promise and challenges. Polymers. 2021;13(5):753. https://doi.org/10.3390/polym13050753

8. Gao X., Qi S., Kuang X., Su Y., Li J., Wang D. Fused filament fabrication of polymer materials: A review of interlayer bond. Additive Manufacturing. 2021;37:101658. https://doi.org/10.1016/j.addma.2020.101658

9. Szymczyk-Ziółkowska P., Łabowska M.B., Detyna J., Michalak I., Gruber P. A review of fabrication polymer scaffolds for biomedical applications using additive manufacturing techniques. Biocybernetics and Biomedical Engineering. 2020;40(2):624–638. https://doi.org/10.1016/j.bbe.2020.01.015

10. At the fringe of the fringe of manufacturing. URL: https://www.voxelmatters.com/wp-content/uploads/2020/04/3dpbm-publishes-Advanced-Materials-am-focus-2020-ebook.pdf.pdf (accessed: 20.06.2023)

11. Shuai X., Zeng Y., Li P., Chen J. Fabrication of fine and complex lattice structure Al2O3 ceramic by digital light processing 3D printing technology. Journal of Materials Science. 2020;55:6771–6782. https://doi.org/10.1007/s10853-020-04503-y

12. Polozov I., Razumov N., Masaylo D., Silin A., Lebedeva Y., Popovich A. Fabrication of silicon carbide fiber-reinforced silicon carbide matrix composites using binder jetting additive manufacturing from irregularly-shaped and spherical powders. Materials. 2020;13(7):1766. https://doi.org/10.3390/ma13071766

13. Cicala G., Latteri A., Del Curto B., Lo Russo A., Recca G., Farè S. Engineering thermoplastics for additive manufacturing: A critical perspective with experimental evidence to support functional applications. Journal of Applied Biomaterials & Functional Materials. 2017;15(1):10–18. https://doi.org/10.5301/jabfm.5000343

14. Francis J.N., Banerjee I., Chugh A., Singh J. Additive manufacturing of polyetheretherketone and its composites: A review. Polymer Composites. 2022;43(9):5802–5919. https://doi.org/10.1002/pc.26961

15. Padmakumar M. Additive manufacturing of tungsten carbide hardmetal parts by selective laser melting (SLM), selective laser sintering (SLS) and binder jet 3D printing (BJ3DP) techniques. Lasers Manufacturing and Materials Processing. 2020;7(3):338–371. https://doi.org/10.1007/s40516-020-00124-0

16. Talignani A., Seede R., Whitt A., Zheng S., Ye J., Karaman I., Kirka M.M., Kato Y., Wang Y.M. A review on additive manufacturing of refractory tungsten and tungsten alloys. Additive Manufacturing. 2022;103009. https://doi.org/10.1016/j.addma.2022.103009

17. Sotov A., Kantyukov A., Popovich A., Sufiiarov V. A review on additive manufacturing of functional gradient piezoceramic. Micromachines. 2022;13(7):1129. https://doi.org/10.3390/mi13071129

18. Sufiiarov V., Kantyukov A., Popovich A., Sotov A. Structure and properties of barium titanate lead-free piezoceramic manufactured by binder jetting process. Materials. 2021;14(16):4419. https://doi.org/10.3390/ma14164419

19. Garces I.T., Ayranci C. Advances in additive manufacturing of shape memory polymer composites. Rapid Prototyping Journal. 2021;27(2):379–398. https://doi.org/10.1108/RPJ-07-2020-0174

20. Sabahi N., Chen W., Wang C.H., Kruzic J.J., Li X. A review on additive manufacturing of shape-memory materials for biomedical applications. JOM. 2020;72(3):1229–1253. https://doi.org/10.1007/s11837-020-04013-x

21. Liu G., Xiong Y., Zhou L. Additive manufacturing of continuous fiber reinforced polymer composites: Design opportunities and novel applications. Composites Communications. 2021;27:100907. https://doi.org/10.1016/j.coco.2021.100907

22. Goh G.D., Yap Y.L., Agarwala S., Yeong W.Y. Recent progress in additive manufacturing of fiber reinforced polymer composite. Advanced Materials Technologies. 2019;4(1):1800271. https://doi.org/10.1002/admt.201800271

23. Frketic J., Dickens T., Ramakrishnan S. Automated manufacturing and processing of fiber-reinforced polymer (FRP) composites: An additive review of contemporary and modern techniques for advanced materials manufacturing. Additive Manufacturing. 2017;14:69–86. https://doi.org/10.1016/j.addma.2017.01.003

24. Map of additive manufacturing technologies. URL: https://www.voxelmatters.com/wp-content/uploads/ 2019/06/3dpbm-Map-of-Additive-Manufacturing-Technologies-and-Companies-1.svg (accessed: 20.06.2023).

25. Sher D. The new map of composites additive manufacturing technologies. URL: https://www.voxelmatters.com/why-a-map-of-composites-additive-manufacturing-technologies-and-companies-matters-now/ (accessed: 20.06.2023).

26. Li H., Li Z., Wang N., Peng Y., Jiang Z., Zhang Q. Improving the mechanical properties of CCFRPLA by enhancing the interface binding energy and strengthening the anti-separation ability of a PLA matrix. Polymers. 2023;15(11):2554. https://doi.org/10.3390/polym15112554

27. Shah A. Emerging trends in robotic aided additive manufacturing. Materials Today: Proceedings. 2022;62:7231–7237. https://doi.org/10.1016/j.matpr.2022.03.680

28. Fry N.R., Richardson R.C., Boyle J.H. Robotic additive manufacturing system for dynamic build orientations. Rapid prototyping journal. 2020;26(4):659–667. https://doi.org/10.1108/RPJ-09-2019-0243

29. Bhatt P.M., Kulkarni A., Malhan R.K., Shah B.C., Yoon Y.J., Gupta S.K. Automated planning for robotic multi-resolution additive manufacturing. Journal of Computing and Information Science in Engineering. 2022; 22(2):021006. https://doi.org/10.1115/1.4052083

30. Lettori J., Raffaeli R., Bilancia P., Peruzzini M., Pellicciari M. A review of geometry representation and processing methods for cartesian and multiaxial robot-based additive manufacturing. International Journal of Advanced Manufacturing Technology. 2022;123(11-12):3767–3794. https://doi.org/10.3390/app11114825

31. Yao Y., Zhang Y., Aburaia M., Lackner M. 3D printing of objects with continuous spatial paths by a multi-axis robotic FFF platform. Applied Sciences. 2021;11(11):4825. https://doi.org/10.3390/app11114825

32. Ginger G. The evolution of additive composites. URL: https://www.compositesworld.com/articles/the-evolution-of-additive-composites (accessed: 20.06.2023).

33. Continuous composites. URL: https://www.continuouscomposites.com/technology (accessed: 21.06.2023).

34. Orbital composites. URL: https://www.orbitalcomposites.com (accessed: 21.06.2023).

35. Moi composites. URL: https://www.moi.am (accessed: 21.06.2023).

36. Davide Sher. Continuous composites demonstrate CF3D continuous fiber composite AM. URL: https://www.voxelmatters.com/continuous-composites-demonstrate-future-continuous-fiber-composite/ (accessed: 21.06.2023).

37. Parmar H., Khan T., Tucci F., Umer R., Carlone P. Advanced robotics and additive manufacturing of composites: towards a new era in Industry 4.0. Materials and Manufacturing Processes. 2022;37(5):483–517. https://doi.org/10.1080/10426914.2020.1866195

38. Furmansti J., Abbott A., Tandon G.P., Flores M., Barnett P., Salviato M., Baur J., Butcher D. Challenges in additively manufactured thermoset continuously reinforced composites. In: Proceedings for the American Society for Composites – Thirty Seventh Technical Conference 2022 (19–21 September 2022). The University of Arizona, Tucson, Arizona, USA. http://dx.doi.org/10.12783/asc37/36427

39. Baur J.W., Abbott A.C., Tandon G.P., Stranberg N.A., Alvarado T.B. Mechanical properties of additively printed, continuous carbon fiber reinforced, thermosetting composites. In: SAMPE 2022 Conference and Exhibition (Charlotte, USA, 23–26 May 2022). Soc. for the Advancement of Material and Process Engineering, 2022.

40. Baur J.W., Abbott A.C., Barnett P.R., Tandon G.P., Furmanski J., Stranberg N.A., Alvarado T.B. Mechanical properties of additively printed, UV cured, continuous fiber unidirectional composites for multifunctional applications. Journal of Composite Materials. 2023;57(4):865–882. https://doi.org/10.1177/00219983221146264

41. Anisoprint. URL: https://anisoprint.com (accessed: 21.06.2023).

42. CEAD. URL: https://ceadgroup.com (accessed: 21.06.2023).

43. De Backer W., Bergs A.P., Van Tooren M.J. Multi-axis multi-material fused filament fabrication with continuous fiber reinforcement. In: AIAA/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference 2018. P. 0091. https://doi.org/10.2514/6.2018-0091

44. Azarov A.V., Kolesnikov V.A., Khaziev A.R. Development of equipment for composite 3D printing of structural elements for aerospace applications. In: IOP Conference Series: Materials Science and Engineering. ACST 2019 (Moscow, 20–21 November 2019). IOP Publishing, 2020. Vol. 934. No. 1. P. 012049. https://doi.org/10.1088/1757-899X/934/1/012049

45. Kallai Z., Dammann M., Schueppstuhl T. Operation and experimental evaluation of a 12-axis robot-based setup used for 3D-printing. In: ISR 2020: 52th International Symposium on Robotics (9 December 2020). Berlin: VDE Verlag, 2020. P. 1–9.

46. Fernandes R.R., Van de Werken N., Koirala P., Yap T., Tamijani A.Y., Tehrani M. Experimental investigation of additively manufactured continuous fiber reinforced composite parts with optimized topology and fiber paths. Additive Manufacturing. 2021;44:102056. https://doi.org/10.1016/j.addma.2021.102056

47. Zhang G., Wang Y., Qiu W., Dong K., Xiong Y. Geometric characteristics of single bead fabricated by continuous fiber reinforced polymer composite additive manufacturing. Materials Today: Proceedings. 2022;70:431–437. https://doi.org/10.1016/j.matpr.2022.09.361

48. Zhang G., Wang Y., Chen Z., Xu X., Dong K., Xiong Y. Robot-assisted conformal additive manufacturing for continuous fibre-reinforced grid-stiffened shell structures. Virtual and Physical Prototyping. 2023;18(1):e2203695. https://doi.org/10.1080/17452759.2023.2203695

49. Ingersoll machine tools. URL: https://en.machinetools.camozzi.com (accessed: 22.06.2023).

50. Electroimpact. URL: https://www.electroimpact.com (accessed: 21.06.2023).

51. Jeff Sloan. Electroimpact launches plug-and-play AFP system. URL: https://www.compositesworld.com/products/electroimpact-launches-plug-and-play-afp-system (accessed: 21.06.2023).

52. Ginger G. Electroimpact’s 6-axis continuous fiber 3D printer, one part of future multi-functional manufacturing cell. URL: https://www.compositesworld.com/news/electroimpacts-6-axis-continuous-fiber-3d-printer-one-part-of-future-multi-functional-manufacturing-cell (accessed: 21.06.2023).

About the Authors

A. V. SotovRussian Federation

Anton. V. Sotov – Cand. Sci. (Eng.), Leading Researcher of the Laboratory “Material design and additive manufacturing”

29 Polytekhnicheskaya Str., St. Petersburg 195251, Russian Federation

A. I. Zaytsev

Russian Federation

Alexander I. Zaytsev – Engineer of the Russian-Chinese Research Laboratory “Functional materials”

29 Polytekhnicheskaya Str., St. Petersburg 195251, Russian Federation

A. E. Abdrahmanova

Russian Federation

Anna E. Abdrahmanova – Engineer of the Laboratory “Material design and additive manufacturing”

29 Polytekhnicheskaya Str., St. Petersburg 195251, Russian Federation

A. A. Popovich

Russian Federation

Anatoly A. Popovich – Dr. Sci. (Eng.), Professor, Director of the Institute of Machinery, Materials, and Transport

29 Polytekhnicheskaya Str., St. Petersburg 195251, Russian Federation

Review

For citations:

Sotov A.V., Zaytsev A.I., Abdrahmanova A.E., Popovich A.A. Additive manufacturing of continuous fibre reinforced polymer composites using industrial robots: A review. Powder Metallurgy аnd Functional Coatings (Izvestiya Vuzov. Poroshkovaya Metallurgiya i Funktsional'nye Pokrytiya). 2024;18(1):20-30. https://doi.org/10.17073/1997-308X-2024-1-20-30