Scroll to:

Simulating multi-material specimen manufacturing from VZh159 and CuCr1Zr alloys via SLM method: Computational modeling and experimental findings

https://doi.org/10.17073/1997-308X-2024-1-73-80

Abstract

Manufacturing of multi-material products through layer-by-layer synthesis poses various challenges encompassing process parameter optimization, equipment calibration, and the mitigation of warping and internal stresses within the manufactured parts. The article investigates the feasibility of simulating the selective laser melting (SLM) process for manufacturing multi-material components, exemplified through specimens composed of the VZh159 nickel alloy and CuCr1Zr copper alloy. The study entails numerical simulations of the printing process, which were then validated against real specimens produced through SLM. Each test specimen was vertically divided into three parts: the top and bottom sections consisted of the VZh159 alloy, while the central part was composed of the CuCr1Zr alloy. Simulations involved using identical process parameters as employed in the printing process. Thermal and mechanical analyses for each part of the multi-material specimen were sequentially addressed, transferring the outcomes of the preceding analysis as initial conditions for subsequent calculations. The study concludes that while the obtained simulation results are indicative, they do not precisely capture the deformation observed in the specimens manufactured via the SLM method. The numerical values of deformations derived from simulation results slightly underestimate the actual deformations, attributed to limitations in the chosen calculation algorithms. For future utilization of numerical computer simulation in the SLM manufacturing of multi-material specimens, the study suggests the necessity of implementing a seamless, continuous simulation process without transitions between different parts of the specimen. This entails considering the entire manufacturing process without segregating sections, ensuring a comprehensive account of continuous deformation and stress accumulation throughout fabrication.

Keywords

For citations:

Orlov A.V., Repnin A.V., Farber E.M., Borisov E.V., Popovich A.A. Simulating multi-material specimen manufacturing from VZh159 and CuCr1Zr alloys via SLM method: Computational modeling and experimental findings. Powder Metallurgy аnd Functional Coatings (Izvestiya Vuzov. Poroshkovaya Metallurgiya i Funktsional'nye Pokrytiya). 2024;18(1):73-80. https://doi.org/10.17073/1997-308X-2024-1-73-80

Introduction

Today, numerous high-tech engineering challenges necessitate the use of products crafted from metals and alloys possessing enhanced and distinct properties that cannot be attained through a singular material composition [1]. Multi-material approaches prove invaluable in addressing such issues – encompassing the incorporation of multiple materials or alloys into a product’s composition. This method enables the amalgamation of their properties or facilitates precise distribution of these attributes, thereby achieving desired qualities like localized wear resistance, elevated thermal conductivity, thermal insulation, resistance to chemical corrosion, among others, at specific points within a product or component [2].

The classification of multi-materials includes compositions like polymer–metal, metal–metal (bimetal), metal–ceramic, among others [3]. Bimetallic products are combinations of two metals or alloys achieved by welding or soldering, effectively mitigating their respective drawbacks while preserving the desired properties of each [4]. For example, copper-based alloys such as GRCop-84 exhibit remarkably high thermal conductivity, facilitating rapid cooling, elevated temperature strength with minimal thermal expansion, and substantial resistance to oxidation. This makes them suitable for applications in combustion chambers, jet sleeves of regenerative-cooled rocket engines (jet linings), and areas exposed to high-temperature gas flows [5; 6]. Conversely, nickel-based alloys like Inconel 718 are renowned for their resistance to high-temperature corrosion, making them prevalent in aerospace applications, especially in gas-turbine and rocket engines due to their impressive tensile and tear strength, coupled with oxidation resistance at elevated temperatures. Nonetheless, these alloys have low thermal conductivity [7; 8]. Consequently, employing copper alloys atop nickel alloys (like Inconel 718 or similar) can enhance the thermal conductivity of products while upholding their strength characteristics [5].

To fabricate these products, both conventional technologies and additive manufacturing techniques are viable, enabling the production of items with intricate, sophisticated geometries [1; 3]. Presently, scientific literature exists detailing the characteristics of bimetallic and functional-gradient products falling under the “nickel alloy – copper alloy” classification (In718–Cu; In718–GRCop-84). These studies employ various methods, including direct energy and material supply processes [5; 6; 9], as well as synthesis processes on substrates, such as selective laser melting (SLM) [10; 11]. The SLM process involves numerous parameters that significantly impact the resultant properties, internal stresses, and potential defects in the manufactured materials and products [12–14]. Fine-tuning these process parameters is a crucial and indispensable aspect of the product development process [15]. Using numerical computer simulations proves pivotal in reducing the duration of parameter refinement and minimizing the cost of potential errors, particularly when fabricating products with intricate geometries [16–18].

Up to this point, simulations of the SLM process have been extensively documented [14; 16; 17; 19]. However, these studies have not addressed the simulation challenges associated with manufacturing products from multi-material compositions, particularly bimetallic products. Therefore, advancing the effective application of additive technologies in producing bimetallic products/parts for diverse purposes necessitates exploring the feasibility of simulating the SLM process for such products.

The objective of this study is to conduct numerical computer simulations of the SLM manufacturing process for multi-material specimens composed of the VZh159 nickel alloy and CuCr1Zr copper alloy. Subsequently, the obtained simulation results will be validated based on the specimens manufactured in the real-world setting.

Materials and methods

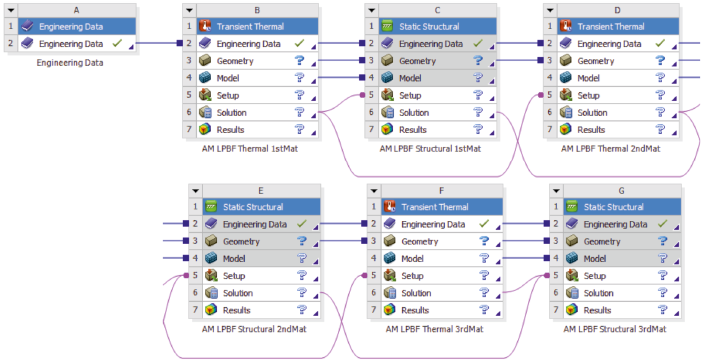

The numerical computer simulation of the multi-material specimen growth via the SLM method was conducted using the finite-element analysis package “ANSYS Workbench 2019 R2” with the utilization of the “Transient Thermal” and “Static Structural” modules [20]. Fig. 1 illustrates the model of the specimen, delineating the material composition of its three distinct parts: top, middle, and bottom. The simulation process involved a sequential resolution of the thermomechanical problem for each segment of the specimen. Initially, the thermal aspect was addressed using the “Transient Thermal” module, followed by the mechanical problem tackled through the “Static Structural” module. Fig. 2 provides a block diagram outlining the steps involved in the numerical computer simulation.

Fig. 1. Initial design of the multi-material specimen

Fig. 2. Block diagram of computer simulation for manufacturing multi-material specimens |

The simulation process for the product growth via the SLM method utilized specific parameters: for the VZh159 alloy – laser power of 275 W, scanning rate at 760 mm/s, distance between laser passes set at 0.1 mm, and a layer thickness of 0.05 mm; for the CuCr1Zr alloy – laser power of 400 W, scanning rate at 300 mm/s, distance between laser passes at 0.15 mm, and a layer thickness of 0.05 mm. Detailed physical and mechanical properties of the alloys employed in the simulation process are provided within a referenced Table.

Physical and mechanical properties of modeled alloys

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

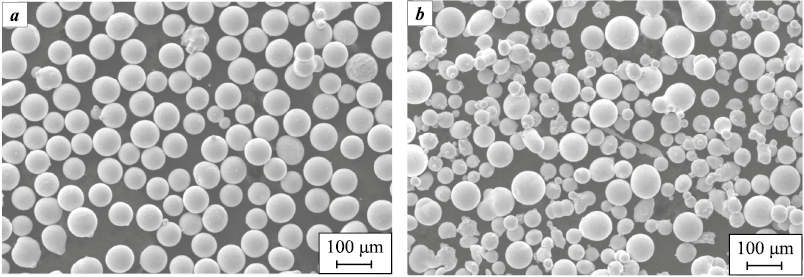

Spherical powders of the VZh159 alloy (with distribution quantiles d10 = 17 μm, d50 = 32 μm, d90 = 55 μm) and CuCr1Zr alloy (with d10 = 14 μm, d50 = 29 μm, d90 = 52 μm) were used to create bimetallic material specimens. Fig. 3 displays SEM images depicting the particles of these powders.

Fig. 3. SEM image of CuCr1Zr (a) and VZh159 (b) alloy powders used in the study |

The manufacturing process occurred within an inert gas atmosphere employing the SLM280HL machine (SLM Solutions GmbH, Germany). This machine is equipped with an ytterbium fiber laser possessing a wavelength of 1070 nm, a maximum power output of 400 W, a minimum laser beam diameter of 80 μm, and a maximum scanning rate of 15 m/s. The produced specimens were constructed with the upper and lower parts comprised of VZh159 alloy, while the middle sections were fashioned from CuCr1Zr alloy.

The examination of the acquired specimens was conducted using a light optical microscope called “Leica DMI 5000” (Leica Microsystems, Germany). To facilitate the examination process, the specimens were sectioned using the electroerosion method.

Results and discussion

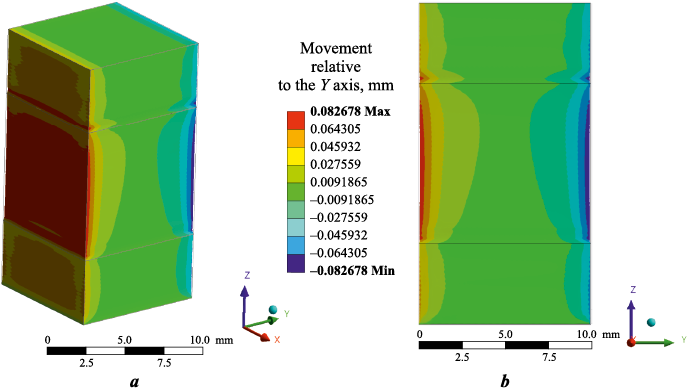

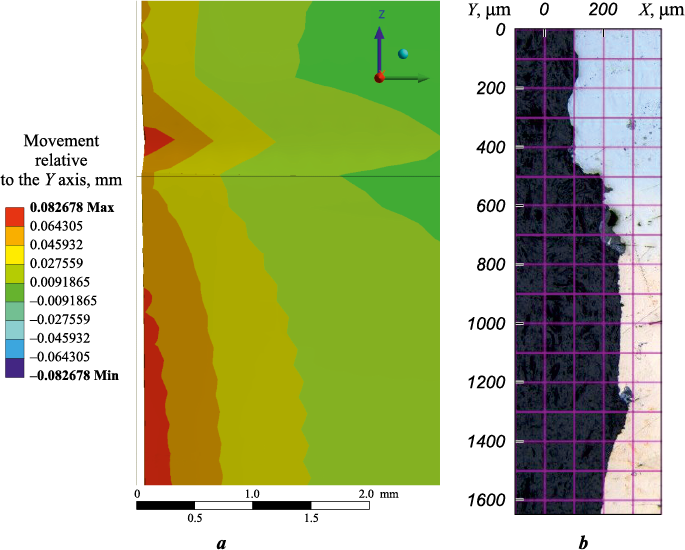

Fig. 4 illustrates the outcomes of simulating the SLM manufacturing process for multi-material specimens, showcasing the deformation fields along the Y-axis. Notably, inward deformation of the specimen’s sides is evident, reaching a maximum deformation of 83 µm.

Fig. 4. Results of simulating of multi-material specimen manufacturing – |

Particularly, the middle section of the specimen made of CuCr1Zr experiences the most significant deformation. Additionally, the top part composed of VZh159 displays considerable deformation, especially at the interfaces between materials.

In Fig. 5, the simulation results portray the stress fields following the production of multi-material specimens via the SLM method. The highest stress values, approximately 900 MPa, are observed at the corners of the specimen at the material interfaces. Elevated stress, ranging from 400 to 500 MPa, is noticeable in the upper part of the specimen fabricated from VZh159. Comparatively, the lowest stress values do not exceed 100 MPa.

Fig. 5. Results of simulating of multi-material specimen manufacturing – specimen stress |

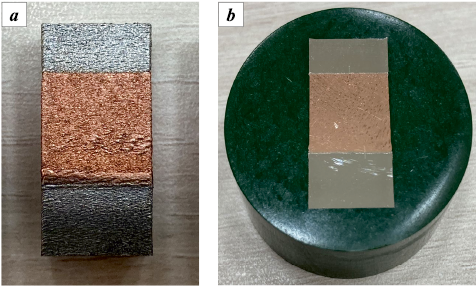

Fig. 6 displays the multi-material specimens made using the SLM method. Visual examination indicates the absence of significant deformations or visible defects such as fractures or failures.

Fig. 6. Manufactured multi-material specimen (a) |

In Fig. 7, the verification of the deformation simulation for the specimen produced via the SLM method is presented, specifically at the interface between its top part (constructed from VZh159) and the middle part (constructed from CuCr1Zr).

Fig. 7. Validation of deformation simulation at the interface between the top and middle parts |

The simulations depicted in Fig. 7, a, revealed deformations ranging from 64 to 83 μm at the interface between the top and middle sections of the specimen, illustrating distinct inward bending occurring separately in both the top and middle parts. Upon experimental examination of the SLM-manufactured specimen (Fig. 7, b), the deformation at the interface measured approximately 100 μm, slightly exceeding the simulated values (with the largest deviation being 36 μm). Inward bending with maximum deformation near the interface is predominantly observed in the middle part of the specimen constructed from CuCr1Zr.

The disparity between the simulation results and experimental data might be attributed to the inherent characteristics of the simulation process. As the simulation initiates the fabrication of the top part of the VZh159 specimen, its middle part ceases to influence stress and deformation calculations, being treated as part of the substrate. This leads to limitations in the acquired values of stresses and deformations. Consequently, the distinct nature of specimen deformation, observed when the simulated specimen deforms in two separate sections, is a direct consequence of this phenomenon. This limitation underscores the challenges in employing simulations for multi-material manufacturing processes using SLM method.

Nonetheless, the deformation values obtained through simulation generally present a representative approximation, closely aligning with the experimental values. However, for more intricate structures, optimizing the system becomes essential to achieve better alignment with real-world results.

Conclusion

Based on the completed research results, several conclusions have been drawn regarding the numerical computer simulation of the manufacturing process for multi-material specimens made from the VZh159 nickel alloy and CuCr1Zr copper alloy.

1. The simulation results, while indicative, do not precisely mirror the deformation observed in the specimen produced via the SLM method. The numerical values of deformations obtained from simulations (from 64 to 83 μm) slightly underestimate the actual deformations (approximately 100 μm). This discrepancy is attributed to the imperfections in the chosen calculation algorithms, particularly when the system stops considering the middle part of the specimen in the calculation and treats it solely as a substrate after initiating the calculation of the top part of the specimen manufacturing.

2. To enable the continued utilization of numerical computer simulation for the growth of multi-material specimens via the SLM method, it is imperative to implement a seamless simulation process without the discontinuity between different parts of the specimen. This involves accounting for the continuous manufacturing process of the specimen, thereby considering uninterrupted deformation and accumulation of stresses throughout the fabrication procedure.

References

1. Bandyopadhyay A., Zhang Y., Onuike B. Additive manufacturing of bimetallic structures. Virtual and Physical Prototyping. 2022;17(2):256–294. https://doi.org/10.1080/17452759.2022.2040738

2. Wang D., Liu L., Deng G., Deng C., Bai Y., Yang Y., Wu W., Chen J., Liu Y., Wang Y., Lin X., Han C. Recent progress on additive manufacturing of multi-material structures with laser powder bed fusion. Virtual and Physical Prototyping. 2022;17(2):329–365. https://doi.org/10.1080/17452759.2022.2028343

3. Nazir A., Gokcekaya O., Md Masum Billah K., Ertugrul O., Jiang J., Sun J., Hussain S. Multi-material additive manufacturing: A systematic review of design, properties, applications, challenges, and 3D printing of materials and cellular metamaterials. Materials & Design. 2023;226: 111661. https://doi.org/10.1016/j.matdes.2023.111661

4. Hasanov S., Alkunte S., Rajeshirke M., Gupta A., Huseynov O., Fidan I., Alifui-Segbaya F., Rennie A. Review on additive manufacturing of multi-material parts: progress and challenges. Journal of Manufacturing and Materials Processing. 2022;6(1):4. https://doi.org/10.3390/jmmp6010004

5. Onuike B., Heer B., Bandyopadhyay A. Additive manufacturing of Inconel 718–Copper alloy bimetallic structure using laser engineered net shaping (LENS™). Additive Manufacturing. 2018;21:133–140. https://doi.org/10.1016/j.addma.2018.02.007

6. Balkan M.E., Aydoğan E., Işık M., Derin B., Koç B. Directed energy deposition process development for functionally gradient Copper–Inconel 718 materials. Journal of Additive Manufacturing Technologies. 2021;1(3):581–581. https://doi.org/10.18416/JAMTECH.2111581

7. Ghorbanpour S., Alam M.E., Ferreri N.C., Kumar A., McWilliams B.A., Vogel S.C., Bicknell J., Beyerlein I.J., Knezevic M. Experimental characterization and crystal plasticity modeling of anisotropy, tension-compression asymmetry, and texture evolution of additively manufactured Inconel 718 at room and elevated temperatures. International Journal of Plasticity. 2020;125:63–79. https://doi.org/10.1016/j.ijplas.2019.09.002

8. Popovich A.A., Sufiiarov V.S., Polozov I.A., Borisov E.V. Microstructure and mechanical properties of Inconel 718 produced by SLM and subsequent heat treatment. Key Engineering Materials. 2015;651–653:665–670. https://doi.org/10.4028/www.scientific.net/KEM.651-653.665

9. Onuike B., Bandyopadhyay A. Bond strength measurement for additively manufactured Inconel 718–GRCop84 copper alloy bimetallic joints. Additive Manufacturing. 2019; 27:576–585. https://doi.org/10.1016/j.addma.2019.04.003

10. Marques A., Cunha Â., Gasik M., Carvalho O., Silva F.S., Bartolomeu F. Inconel 718–copper parts fabricated by 3D multi-material laser powder bed fusion: a novel technological and designing approach for rocket engine. International Journal of Advanced Manufacturing Technology. 2022;122(3-4):2113–2123. https://doi.org/10.1007/s00170-022-10011-x

11. Walker J., Middendorf J.R., Lesko C.C.C., Gockel J. Multi-material laser powder bed fusion additive manufacturing in 3-dimensions. Manufacturing Letters. 2022;31:74–77. https://doi.org/10.1016/j.mfglet.2021.07.011

12. Papazoglou E.L., Karkalos N.E., Karmiris-Obratański P., Markopoulos A.P. On the modeling and simulation of SLM and SLS for metal and polymer powders: A review. Archives of Computational Methods in Engineering. 2022; 29:941–973. https://doi.org/10.1007/s11831-021-09601-x

13. Wei C., Zhang Z., Cheng D., Sun Z., Zhu M., Li L. An overview of laser-based multiple metallic material additive manufacturing: from macro- to micro-scales. International Journal of Extreme Manufacturing. 2021;3(1):012003. https://doi.org/10.1088/2631-7990/abce04

14. Song X., Feih S., Zhai W., Sun C.N., Li F., Maiti R., Wei J., Yang Y., Oancea V., Romano Brandt L., Korsunsky A.M. Advances in additive manufacturing process simulation: Residual stresses and distortion predictions in complex metallic components. Materials & Design. 2020;193: 108779. https://doi.org/10.1016/j.matdes.2020.108779

15. Nandhakumar R., Venkatesan K. A process parameters review on selective laser melting-based additive manufacturing of single and multi-material: Microstructure, physical properties, tribological, and surface roughness. Materials Today Communications. 2023;35:105538. https://doi.org/10.1016/j.mtcomm.2023.105538

16. Gh Ghanbari P., Mazza E., Hosseini E. Adaptive local-global multiscale approach for thermal simulation of the selective laser melting process. Additive Manufacturing. 2020; 36:101518. https://doi.org/10.1016/j.addma.2020.101518

17. Zhou R., Liu H., Wang H. Modeling and simulation of metal selective laser melting process: a critical review. International Journal of Advanced Manufacturing Technology. 2022;121(9-10):5693–5706. https://doi.org/10.1007/s00170-022-09721-z

18. Bouabbou A., Vaudreuil S. Understanding laser-metal interaction in selective laser melting additive manufacturing through numerical modelling and simulation: A review. Virtual and Physical Prototyping. 2022;17(3):543–562. https://doi.org/10.1080/17452759.2022.2052488

19. Laakso P., Riipinen T., Laukkanen A., Andersson T., Jokinen A., Revuelta A., Ruusuvuori K. Optimization and simulation of SLM process for high density H13 tool steel parts. Physics Procedia. 2016;83:26–35. https://doi.org/10.1016/j.phpro.2016.08.004

20. Nagesha B.K., Anand Kumar S., Vinodh K., Pathania A., Barad S. A thermo-mechanical modelling approach on the residual stress prediction of SLM processed HPNGV aeroengine part. Materials Today: Proceedings. 2021;44: 4990–4996. https://doi.org/10.1016/j.matpr.2020.12.940

About the Authors

A. V. OrlovRussian Federation

Aleksei V. Orlov – Researcher, Laboratory “Design of materials and additive manufacturing”

29 Polytekhnicheskaya Str., St. Petersburg 195251, Russian Federation

A. V. Repnin

Russian Federation

Arseniy V. Repnin – Engineer, Laboratory “Synthesis of new materials and structures”

29 Polytekhnicheskaya Str., St. Petersburg 195251, Russian Federation

E. M. Farber

Russian Federation

Eduard M. Farber – Engineer, Laboratory “Synthesis of new materials and structures”

29 Polytekhnicheskaya Str., St. Petersburg 195251, Russian Federation

E. V. Borisov

Russian Federation

Evgeny V. Borisov – Cand. Sci. (Eng.), Leading Researcher, Laboratory “Synthesis of new materials and structures”

29 Polytekhnicheskaya Str., St. Petersburg 195251, Russian Federation

A. A. Popovich

Russian Federation

Anatoly A. Popovich – Dr. Sci. (Eng.), Professor, Director of the Institute of Machinery, Materials, and Transport

29 Polytekhnicheskaya Str., St. Petersburg 195251, Russian Federation

Review

For citations:

Orlov A.V., Repnin A.V., Farber E.M., Borisov E.V., Popovich A.A. Simulating multi-material specimen manufacturing from VZh159 and CuCr1Zr alloys via SLM method: Computational modeling and experimental findings. Powder Metallurgy аnd Functional Coatings (Izvestiya Vuzov. Poroshkovaya Metallurgiya i Funktsional'nye Pokrytiya). 2024;18(1):73-80. https://doi.org/10.17073/1997-308X-2024-1-73-80