Scroll to:

Structural characteristics and mechanical properties of heat-resistant TNM-B1 alloy obtained by selective laser melting from SHS powder spheroidized in thermal plasma

https://doi.org/10.17073/1997-308X-2024-4-69-82

Abstract

The TNM-B1 + Y2O3 alloy powders obtained by the method of self-propagating high-temperature synthesis were studied. The influence of particle processing parameters in thermal plasma, generated by a DC (direct current) arc plasma torch, on the morphology and structure of spherical particles was considered. It was established that plasma treatment significantly changes the shape of the particles and allows obtaining a product with a high degree of spheroidization (from 88 to 97 %), which depends on the plasma stream temperature, the composition of the plasma-forming gas, and the amount of processed material. Using hydrogen-containing thermal plasma, the degree of spheroidization can reach 99 %. At the same time, the concentrations of impurity oxygen decrease from 0.8 to 0.13 wt. %, nitrogen decreases by 2 times, and the concentration of hydrogen significantly drops. Studies were conducted to develop selective laser melting regimes, resulting in samples with minimal defects. The optimal volumetric energy density of the laser was 40–50 J/mm3. The gasostatic treatment process allowed achieving almost complete uniformity of the samples’ structure and the absence of pores. Additionally, thermal treatment at t = 1380 °C and τ = 120 min contributed to the transformation of the initial equiaxed structure of the alloy into a lamellar one. According to the results of thermomechanical tests under the scheme of uniaxial compression in the temperature range from 800 to 1100 °C, it was established that the alloy with a lamellar structure after selective laser melting, hot isostatic pressing, and thermal treatment has increased strength values by 80–100 MPa compared to the globular structure. The mechanical properties of the alloy with a lamellar structure at t = 800 °C are: modulus of elasticity E = 115.2 GPa, yield strength σ0.2 = 528 MPa, compressive strength σu = 1148 MPa, and at t = 1100 °C: E = 48.2 GPa, σ0.2 = 98 MPa, σu = 149 MPa.

Keywords

For citations:

Markov G.M., Fadeev A.A., Skirpichnikova A.A., Loginov P.A., Khomutov M.G., Samokhin A.V., Levashov E.A. Structural characteristics and mechanical properties of heat-resistant TNM-B1 alloy obtained by selective laser melting from SHS powder spheroidized in thermal plasma. Powder Metallurgy аnd Functional Coatings (Izvestiya Vuzov. Poroshkovaya Metallurgiya i Funktsional'nye Pokrytiya). 2024;18(4):69-82. https://doi.org/10.17073/1997-308X-2024-4-69-82

Introduction

Heat-resistant alloys based on titanium aluminides TiAl/Ti3Al are of significant interest for technical applications in mechanical engineering [1; 2]. They are characterized by high heat resistance, corrosion resistance, and creep resistance. Under the influence of high temperatures and aggressive environments, these alloys maintain thermodynamic stability and, in addition, have low density (~5 g/cm3), which makes their specific strength superior to that of modern nickel-based superalloys of similar purpose (~9 g/cm3) [3–5].

The primary challenges hindering the use of TiAl/Ti3Al-based alloys in the manufacture of complex-shaped parts include high sensitivity of the phase composition to process parameters, impurities, and variations in the concentrations of alloying elements, as well as the difficulty of processing at room temperature. Producing such parts through traditional metallurgical methods followed by mechanical processing involves high capital costs and significant material losses [6]. Modern additive manufacturing technologies, such as selective laser melting (SLM), can address these issues by minimizing the need for mechanical processing [4; 5]. Active research is underway to optimize the compositions and production methods of heat-resistant alloy powders [6–9].

One method for producing TiAl/Ti3Al-based alloy powders utilizes the technology of self-propagating high-temperature synthesis (SHS) [10; 11]. The potential of this method lies in the heterogeneity scale of powder particles with increased reactive surface area due to the high speed of combustion wave propagation, allowing the production of powder materials of the required composition [12–14]. Using this technology, products from basic TiAl/Ti3Al alloys have been manufactured [15].

The development of the SLM process opens up prospects for the creation of complex-shaped products from TiAl/Ti3Al-based materials [5; 12]. In the SLM technology, narrow particle size distribution spherical powders, are used as raw materials, which must meet specific requirements for chemical composition, impurity content, and properties such as bulk density, flowability, granulometric composition, and sphericity.

Based on these requirements, spheroidized powders from TiAl/Ti3Al-based alloys can be obtained using gas atomization, plasma rotating electrode process (PREP method) and plasma spheroidization technologies [16–20], which ensure rapid melt crystallization, contributing to the reduction of grain size and the formation of a homogeneous structure in the solid state. Producing such powders by gas atomization and PREP methods involves using pre-manufactured cast billets and rods, increasing the process cost [18; 21–23]. Plasma spheroidization allows the use of precursor powders as raw materials, significantly simplifying the technology. Under high temperatures and the influence of surface tension forces, particles of arbitrary shape melt, acquire a spherical shape, and crystallize. This processing method improves many powder characteristics for further use in additive technologies: it increases flowability and bulk density; reduces impurity oxygen content; and helps remove internal pores formed in the original particles [24–27].

The aim of this work was to produce spherical powders in the 10–65 μm fraction from the TNM-B1 + Y2O3 alloy based on titanium aluminide, to study the influence of particle processing parameters in thermal plasma generated by a DC arc plasma torch on the morphology, structure, and properties of the powders, and to use these powders in selective laser melting technology.

Materials amd methods

As the starting material, powders of a reactive mixture of pure elements were used to produce the TNM-B1 alloy modified with yttrium oxide (Y2O3 ) by the SHS method in a thermal explosion mode [14]. Pressed billets of the reactive mixture were placed in a tube furnace heated to 900 °C to initiate bulk combustion. The synthesis products were sequentially ground to a powder with particle sizes <100 μm using a jaw crusher and a planetary ball mill Activator-4M (Russia). Narrow particle size distribution spherical powders with grain sizes of 10–65 μm were obtained using an air classifier Golf-3 (Russia).

The classified powders were processed in a thermal plasma stream using a powder spheroidization unit developed by the Baikov Institute of Metallurgy and Materials Science (Moscow, Russia) [28]. The parameters for the spheroidization process of micropowders in the thermal plasma stream are as follows:

Plasma torch power (Npl ), kW . . . . . . . . . . . . . . . . 11– 25

Plasma-forming gases . . . . . . . . . . . . . . . . . . . . . . . Ar, Ar + H2

Plasma gas flow rate (Gpl.g ), m3/h . . . . . . . . . . . . . 2.0–2.16

Plasma stream enthalpy (Ipl), kW·h/m3 . . . . . . . . . 2.0–3.9

Precursor feed rate (Gpr ), kg/h . . . . . . . . . . . . . . . . 0.6–2.4

Transport gas flow rate – Ar(Gtr.g ), m3/h . . . . . . . . 0.5

The plasma jet is generated by a DC arc plasma torch with a power of 30 kW and flows into a water-cooled plasma reactor with a diameter of 300 mm and a length of 1000 mm. The particles of the processed material are introduced into the plasma jet as a gas-dispersed flow using a carrier gas. During particle heating, melting occurs, and spherical shapes form due to surface tension forces. The particles then crystallize, deposit on the inner surface of the plasma reactor, and partially exit to the waste gas filtration system. A reactor wall cleaning system collects and accumulates the product in receiving hoppers.

During plasma processing of the precursor powder with a wide particle size distribution, a nanosized fraction may form due to the partial evaporation of small particles and the condensation of vapors. The presence of this fraction significantly degrades the physical and technological properties of the final product and increases oxygen and nitrogen impurities due to active oxidation of nanoparticles in contact with air. The nanosized fraction was removed from the spheroidized product by sedimentation in distilled water after ultrasonic treatment. The target product was dried under low vacuum conditions at t = 150 °C for 180 min.

The granulometric composition of the powders was measured by laser diffraction in a liquid medium using an ANALYSETTE 22 MicroTec plus device (FRITSCH, Germany) according to ASTM B822-17. Powder flowability was assessed using a Hall funnel (calibrated funnel diameter 2.5 mm) by the standard ASTM-B213 2017 test method. Bulk density was measured according to GOST 19440-94. Impurity oxygen content was determined by reductive melting using a TC-600 instrument (LECO, USA) according to the standard ASTM E1019-18 test method.

The construction and optimization of selective laser melting (SLM) modes were carried out on an SLM-260 setup (SLM Solutions, Germany) in an inert atmosphere. The scanning speed and power were varied in the ranges of 100–1000 mm/s and 50–300 W, respectively. To eliminate defects such as pores and microcracks, SLM samples were additionally subjected to hot isostatic pressing (HIP), and to modify the structure type after HIP, they were thermally treated (HIP + TT). The HIP process was performed on a HIRP10/26–200 setup (ABRA AG, Switzerland) at a temperature of t = 1240 °C, argon pressure PAr = 200 atm, and isothermal holding time τ = 120 min. Thermal treatment was conducted in a Termionik-T1 vacuum furnace (Russia) with a tungsten heater at t = 1380 °C and τ = 120 min.

Phase composition was studied by X-ray phase (XRD) analysis on a D2 PHASER diffractometer (Bruker AXS GmbH, Germany) using CuKα radiation in the 2θ angle range of 10–120° with a step size of 0.02° and exposure of 0.6 s.

Microstructural investigations were carried out on an S-3400 N scanning electron microscope (Hitachi, Japan) with an energy-dispersive attachment NORAN System 7 X-ray Microanalysis System (Thermo Scientific, USA).

Thermomechanical tests under uniaxial compression were conducted in a vacuum (~10\(^–\)3 Pa) on a Gleeble System 3800 instrument (Dynamic Systems Inc., USA). Hot deformation diagrams of samples under compressive stress were recorded in the temperature range of 800 to 1100 °C at a strain rate dε/dt ≤ 0.001 s\(^–\)1.

Results and discussion

Precursor powder structure

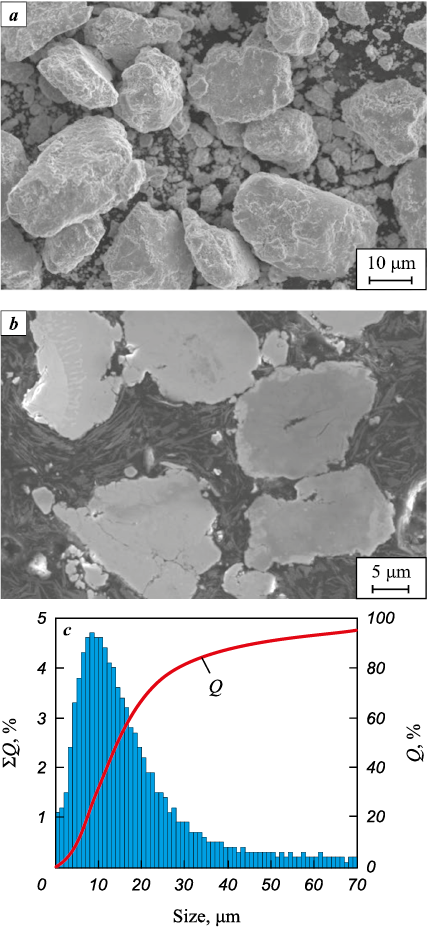

The SHS powder was characterized by the presence of irregularly shaped particles and consisted of γ-TiAl and α2-Ti3Al phases [15]. According to the structural studies (Fig. 1, a, b), it has a homogeneous microstructure, which is an important condition for obtaining high-quality spheroidized powder.

Fig. 1. Morphology (a), microstructure (b) and granulometric composition (c) |

As shown by laser diffraction analysis (Fig. 1, c), the powders have a unimodal distribution with a peak at ~10 μm. The quantile distribution of particles sizes D10 , D50 , and D90 of the powders was 24, 40, and 68 μm, respectively. Since separation in the air classifier is predominantly based on particle mass, some particles larger than 70 μm were included in the target fraction due to their irregular shape. The presence of a fraction smaller than 20 μm is explained by the developed surface of the particles and their mechanical interlocking. The physical and technological properties of the powders largely determine the parameters of their subsequent spheroidization in the thermal plasma stream, where a high degree (>95 %) of sphericity is required [28]. The initial SHS micropowders did not exhibit flowability, and their bulk density was 1.5 g/cm3.

Plasma spheroidization

Plasma spheroidization experiments were conducted with variations in the following parameters: plasma stream enthalpy, plasma-forming gas composition, and precursor powder feed rate. The main criteria for selecting the optimal plasma treatment mode for the powders were the degree of spheroidization and the minimization of the nanosized fraction in the processed powders. One significant parameter of plasma spheroidization, determining the energy contribution to the process and affecting the properties of the resulting product, is the plasma stream enthalpy value. The properties of the spheroidized product varied depending on this parameter within the range of 2 to 3.85 kW·h/m3, determined by the useful power level of the DC arc plasma torch, the composition, and the flow rate of the plasma-forming gas.

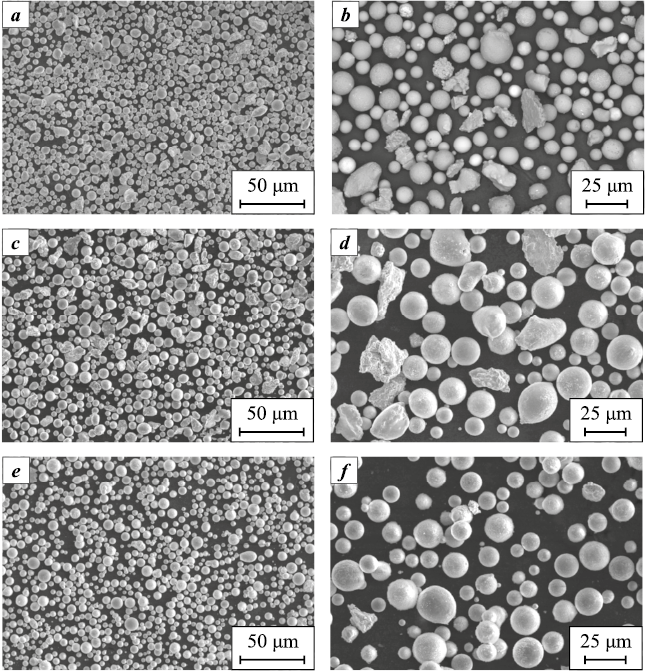

At the minimum enthalpy of the argon-hydrogen plasma stream Ipl = 2 kW·h/m3, the spheroidization degree of the product was ~73 %, which is low for powders intended for use in additive manufacturing processes (Fig. 2, a, b). Material evaporation with the formation of the nanosized fraction was practically absent, flowability was 57 s/50 g, and bulk density was 2.1 g/cm3.

Fig. 2. Morphology of powders after spheroidization at an argon-hydrogen plasma |

Increasing Ipl > 2 kW·h/m3 significantly raised the heat flow density to the surface of the processed powder particles, positively affecting the intensification of heating and melting particles, and consequently, increasing their spheroidization degree. However, a negative aspect of this process is the increased evaporation intensity of particles due to overheating, leading to a higher concentration of condensed nanoparticles in the spheroidized powder. Experiments showed that the maximum spheroidization degree was achieved at an argon-hydrogen plasma stream enthalpy of Ipl = 3.85 kW·h/m3. Changing its value from 2 to 3.85 kW·h/m3 increased the spheroidization degree from 73 to 96 %. The nanosized fraction content increased slightly (to 2.1 wt. %), flowability reached 38 s/50 g, and bulk density increased to 2.45 g/cm3.

Research found that processing the precursor powder in argon plasma produced a product with a spheroidization degree of 96 %. The presence of agglomerates and particles with satellites was noted (Fig. 3, b). To increase the spheroidization degree at a fixed electric arc power value, the heat transfer conditions in the “hot gas-particle” system must be changed. One possible solution is to increase the thermal conductivity of the gas medium by adding hydrogen to the plasma-forming gas. Using hydrogen-containing thermal plasma intensifies heat and mass transfer processes, reducing the heating time of processed particles, resulting in a spheroidization degree of up to 99 % (Fig. 3, a). It was also found that hydrogen-containing plasma creates conditions for partial reduction of the precursor powder, leading to a decrease in oxygen impurity concentration in the product.

Fig. 3. Morphology of powders after spheroidization in plasma stream: Ar–H2 (а, c), Ar (b, d) |

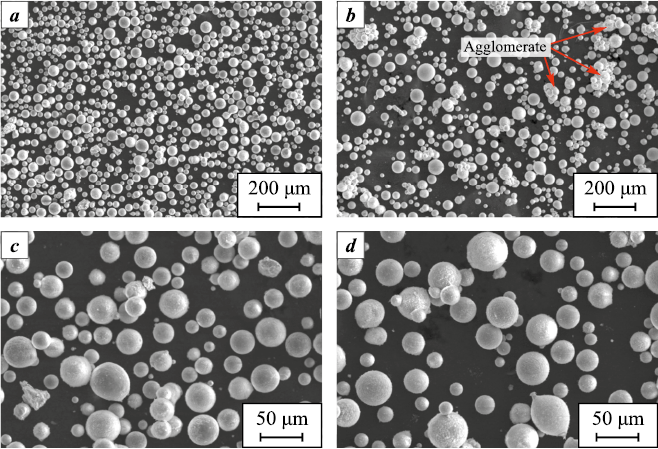

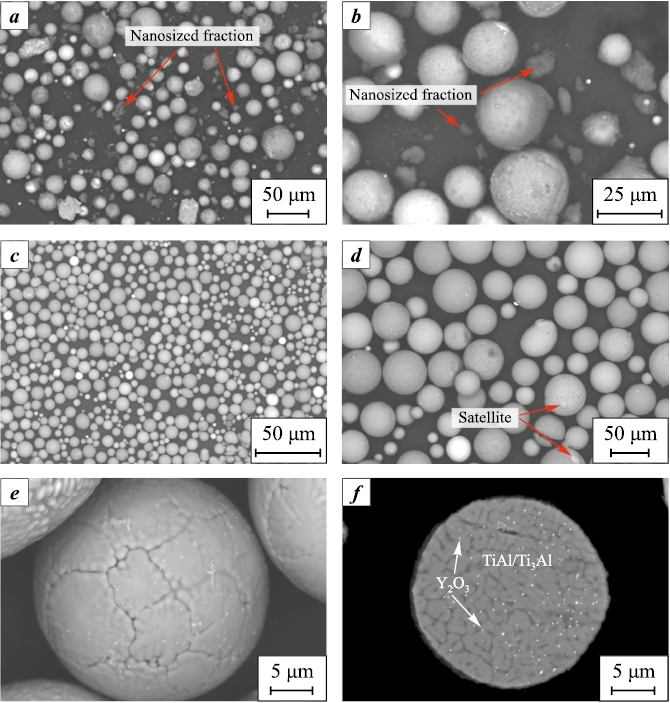

Increasing the precursor powder feed rate requires more thermal energy from the plasma stream to heat the material, reducing the spheroidization degree. Thus, increasing the precursor feed rate from 0.6 to 2.4 kg/h decreased the spheroidization degree to 88 %, while the nanosized fraction content decreased to 2.1 wt. %. The maximum spheroidization degree (96 %) at a minimal nanosized fraction content was achieved with a precursor feed rate of 1.2 kg/h. As previously shown, micropowders obtained by plasma spheroidization (Fig. 4, a, b) contain nano- and submicron-sized particles formed by partial evaporation of the processed material and subsequent vapor condensation during cooling of the high-temperature gas-dispersed flow. Particle content varied from 3 to 10 wt. %.

Fig. 4. Morphology of TNM-B1 + 1 % Y2O3 alloy powder after treatment in Ar–H2 plasma |

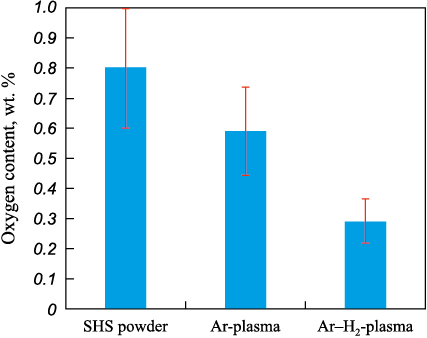

A suitable spheroidized powder for SLM technology was obtained with an Ar–H2 plasma stream enthalpy with 3.7 vol. % hydrogen, corresponding to Ipl = 3.8 kW·h/m3. Partial evaporation of the precursor led to the appearance of a nanosized fraction Mnf = 7 wt. %, and the spheroidization degree reached 99 % (Fig. 4, c–e). The spherical particles exhibited a homogeneous globular TiAl/Ti3Al structure with Y2O3 nanoparticles at grain boundaries (Fig. 4, f). The flowability of the resulting powders was 29 s/50 g, and bulk density increased to 2.5 g/cm3. D10 , D50 , and D90 parameter values were 17, 29, and 50 μm, respectively, within a particle size range of 10 to 79 μm. It should be noted that processing the powder in argon plasma reduces oxygen impurities from 0.8 to 0.6 wt. %, while hydrogen-containing thermal plasma treatment, along with removing the nanosized fraction, reduces oxygen impurities to 0.3 wt. % (Fig. 5) and halves nitrogen impurities. Hydrogen content remained at 0.0025 wt. %.

Fig. 5. Impurity oxygen content in the starting SHS powder |

Selective laser melting

The obtained powder was used to optimize the SLM modes on the SLM-260 setup (SLM Solutions, Germany). The optimal ranges of the main parameters of laser synthesis were selected, considering the minimum volumetric energy density (VED) required to melt a powder layer of a given thickness, using the following formula:

\[VED = \frac{P}{{vhtd}},\]

where P is the laser power, W; v is the scanning speed, mm/s; h is the hatch spacing, mm; t is the powder layer thickness, mm; d is the laser beam diameter, mm.

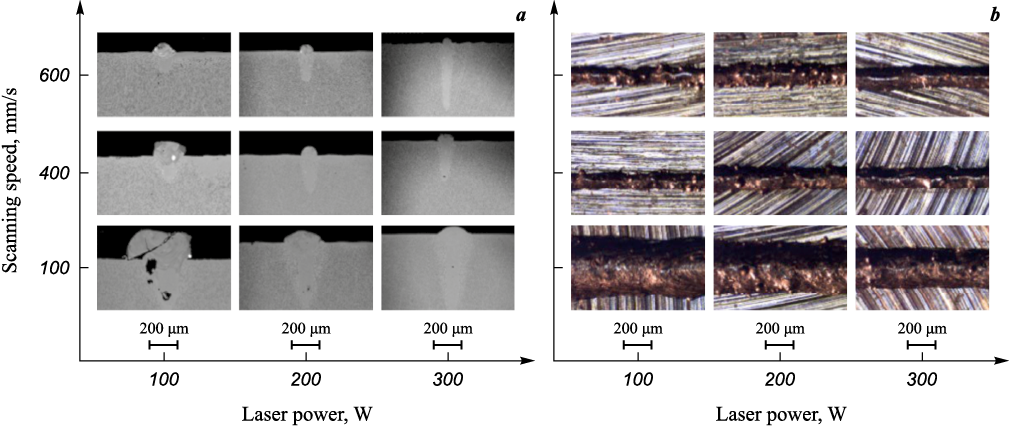

The optimization of SLM modes using the spherical TNM-B1 + Y2O3 powder involved creating single tracks and evaluating the depth of melt and the presence of defects. The results of laser processing of single tracks revealed several patterns (Fig. 6). Low scanning speeds (v < 200 mm/s) lead to a significant increase in the depth of melt for single tracks (up to 500 μm) regardless of the applied power, while high values of v caused significant track widening. In volumetric printing, this leads to multiple remelts of adjacent tracks, and creates conditions for the formation of excessive stress and subsequent cracking of the material.

Fig. 6. SEM images of cross-section of tracks (a), and their surface images |

Increasing the scanning speed from 200 to 600 mm/s reduced the number of unmelted particles on the track surface, and the track width became more uniform, ranging from 110 to 160 μm. Tracks obtained at higher scanning speeds had a smooth and uniform surface with a low number of defects. The optimal microstructure of the tracks was obtained at v = 500÷600 mm/s, and simultaneously increasing the laser power required v > 900 mm/s, corresponding to a volumetric energy density range of VED = 40÷110 J/mm3. Further variation of power and scanning speed for creating bulk samples was conducted within the established VED range.

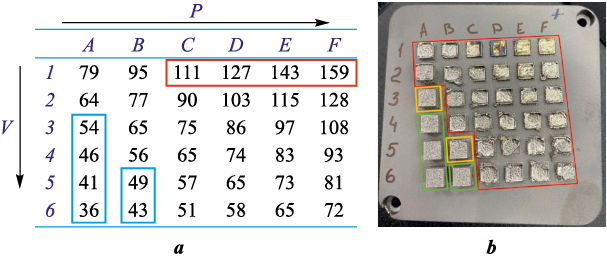

Fig. 7, a shows the matrix of volumetric energy density values and a platform with bulk samples. Power variation was conducted within 70–115 W, and scanning speeds in the range of 500–1000 mm/s. Samples can be divided into three groups based on characteristic defects. In Fig. 7, b, samples with warping during construction are highlighted in red, those with contour delamination in yellow, and defect-free samples in green.

Fig. 7. SLM modes and platform with constructed samples |

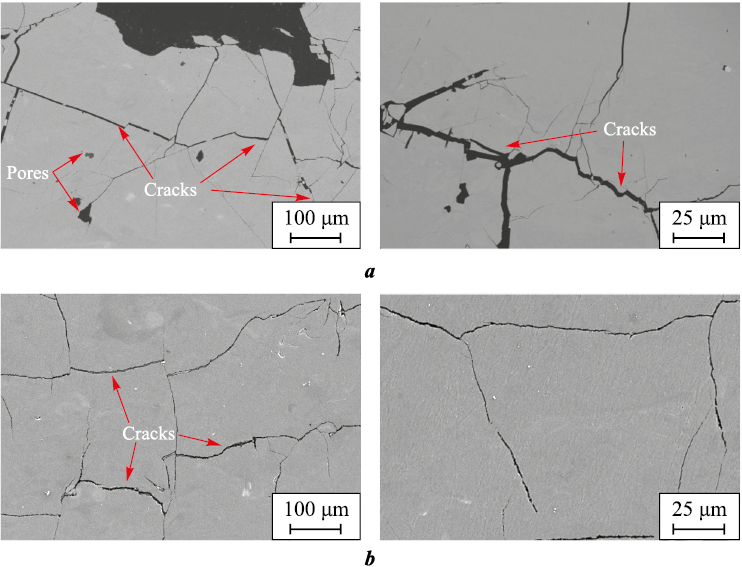

For most construction modes, especially at high laser energy density (160 J/mm3), complete sample construction was not achieved. This was due to insufficient heat transfer and melt overheating, leading to warping, as well as the formation of cavities and cracks. Visual control of the SLM process for each subsequent printed layer required stopping printing for some modes due to pronounced warping of the growing samples. These modes, characterized by low laser power (70 W), ensured the formation of a dense microstructure with a uniform distribution of alloying elements. However, microcracks were present in the samples (Fig. 8, a), formed due to internal stress from strong temperature gradients.

Fig. 8. Microstructures of bulk SLM samples obtained during the optimization |

As seen in Fig. 8, b, reducing the volumetric energy density to 50 J/mm3 and simultaneously lowering the laser power and scanning speed prevented melt pool overheating and suppressed the formation of most microcracks in the sample structures. A small number of submicron pores (<3 vol. %) were noted in these samples’ structures, formed by argon entrapment in the melt pool.

Post-processing and mechanical testing

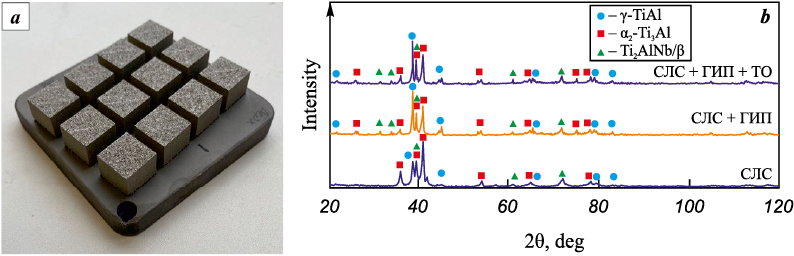

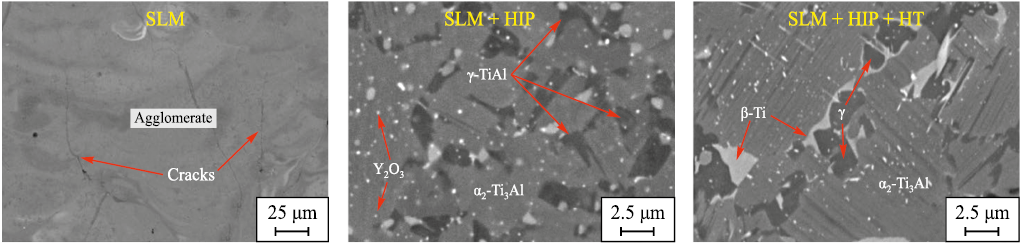

The obtained samples of the TNM-B1 + Y2O3 alloy with optimal structure under mode A5 (Fig. 9, a) were subjected to HIP and heat treatment. X-ray diffraction patterns were recorded after three types of treatment (SLM, SLM + HIP, and SLM + HIP + HT) and phase identification was conducted (Fig. 9, b). The TNM-B1 + Y2O3 alloy obtained by SLM predominantly contained the α2-Ti3Al phase (60 wt. %). Its concentration was 3–4 times higher than the equilibrium [14]. Phase formation processes in alloys similar to TNM-B1 + Y2O3 are primarily controlled by the cooling rate. High cooling rates typical of SLM suppress the eutectoid reaction α → α2 + γ, resulting in an excess of the α2-Ti3Al [11].

Fig. 9. Bulk samples of the TNM-B1 + Y2O3 alloy obtained by SLM (a) |

HIP treatment brought the SLM TNM-B1 + Y2O3 alloy to an equilibrium state by transforming metastable α2-Ti3Al into γ-TiAl. As seen from the diffraction spectra of the SLM samples (Fig. 10), the intensity of the tetragonal γ-TiAl phase peaks significantly increased after HIP. The γ-TiAl : α2-Ti3Al ratio in them was 75:20. It should be noted that both the SLM and HIP samples contained 5–7 % β-Ti phase, which was not previously observed in this alloy obtained by HIP technology from SHS powders [15]. The SLM method for consolidation involves higher temperatures and material transition to the liquid phase, with crystallization starting with the formation of primary β-Ti crystals according to the Ti–Al phase diagram. These β-Ti phase grains remain in the alloy after SLM and HIP (Fig. 10).

Fig. 10. Microstructures of the TNM-B1 + Y2O3 alloy after various types of treatment |

Heat treatment (HT) did not lead to significant changes in phase composition (Fig. 9, b): the γ-TiAl : α2-Ti3Al ratio remained 75:20. At this stage, heating above the eutectoid transformation temperature α → α2 + γ was carried out. As a result of slow cooling, equiaxed α-phase grains decomposed into colonies of γ-TiAl: α2-Ti3Al lamellae (Fig. 10).

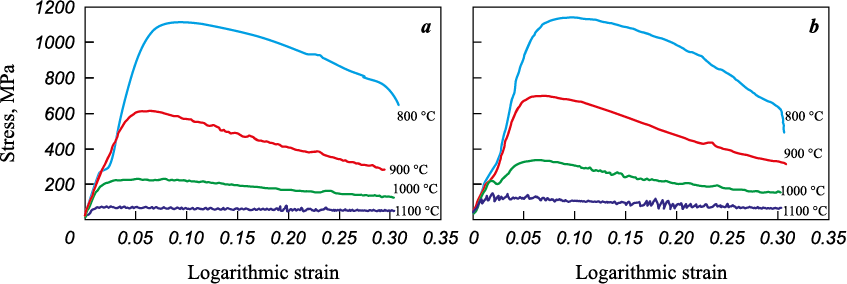

Structural and phase changes in SLM samples occurring during HIP and HT undoubtedly affect the properties of the TNM-B1 + Y2O3 alloy. Fig. 11 shows deformation diagrams in the “true stress – logarithmic strain” coordinates for samples obtained under SLM mode A5, SLM + HIP, and SLM + HIP + HT. The porosity of the samples after HIP and HIP + HT did not exceed 1%. It was found that the obtained properties strongly depend on the test temperature. All deformation curves exhibit a pronounced maximum corresponding to the compressive strength and indicating the deformation hardening of the samples. All curves have a second section where deformation increases as stress decreases. This effect is explained by dynamic recrystallization or dynamic recovery and relaxation of crystal lattice defects.

Fig. 11. Deformation diagrams under uniaxial compression in the coordinates |

Mechanical properties (elastic modulus E, yield strength σ0.2 , ultimate compressive strength σu ) of the TNM-B1 + Y2O3 alloy after HIP and HIP + HT were determined using deformation diagrams (in the elastoplastic transition region). The σ0.2 values of the obtained samples at 800 °C are comparable to those of cast TNM-B1 alloys (σ0.2 = 400÷530 MPa), and the σu value increased by 150–200 MPa compared to cast alloys (σu = 880÷1000 MPa), due to the finer grain structure [29; 30] (see Table).

Mechanical properties of TNM-B1 + Y2O3 alloy

| |||||||||||||||||||||||||||||||||||||||||||||||

HT of the TNM-B1 + Y2O3 alloy samples after SLM + HIP increases σu by 20–100 MPa due to the formation of a lamellar microstructure. The strengthening effect is more noticeable at high test temperatures (900 to 1100 °С).

Conclusions

1. Powders of the 10–65 μm fraction with a high degree of particle spheroidization (up to 99 %) were obtained from SHS powders of the TNM-B1 + Y2O3 alloy. The influence of particle processing parameters in thermal plasma generated by a DC plasma torch was studied. It was found that this leads to significant changes in particle morphology and the production of a product with a high degree of spheroidization ranging from 88 to 97 %, depending on plasma stream enthalpy, plasma-forming gas composition, and precursor feed rate. At the maximum spheroidization degree, partial precursor evaporation was noted, leading to the formation of up to 7 wt. % of the nanosized fraction.

2. It was established that using hydrogen-containing thermal plasma increases the spheroidization degree of the product up to 99 %. At the same time, increasing the precursor feed rate from 0.6 to 2.4 kg/h decreases the spheroidization degree from 97 to 88 %. When processing powder in hydrogen-containing thermal plasma, the impurity oxygen concentration decreases from 0.8 to 0.13 wt. %, nitrogen impurities are halved, and hydrogen concentration decreases by an order of magnitude.

3. Experiments to optimize the SLM process identified regimes that allow building preforms with minimal defects and residual porosity. The best samples were obtained at a volumetric laser energy density of 40–50 J/mm3 (laser power around 60 W) and a scanning speed above 900 mm/s.

4. The influence of post-processing (HIP and HT) on the structure, phase composition, and mechanical properties of SLM samples from the TNM-B1 + Y2O3 alloy was studied. After HIP, the samples had nearly zero porosity with complete healing of structural defects, and additional thermal treatment ensured the transformation of the alloy’s equiaxed structure into a lamellar one.

5. Thermomechanical tests under uniaxial compression in the temperature range of 800 to 1100 °C revealed that the alloy with a lamellar structure in the SLM + HIP + HT state has increased strength values by 80–100 MPa. The best samples had the following properties at t = 800 °C: E = 115.2 GPa, σ0.2 = 528 MPa, σu = 1148 MPa, and at 1100 °C: E = 48.2 GPa, σ0.2 = 98 MPa, σu = 149 MPa.

References

1. Liu B., Liu Yo. Powder metallurgy titanium aluminide alloys. Titanium powder Metallurgy. Science, Technology and Applications. 2015;27:515–531. https://doi.org/10.1016/B978-0-12-800054-0.00027-7

2. Gupta R.K., Pant B. Titanium aluminides. Intermetallic matrix composites. Properties and Applications. 2018;4:71–93. https://doi.org/10.1016/B978-0-85709-346-2.00004-2

3. Niu H.Z., Chen X.J., Chen Y.F., Zhao S., Liu G.H., Zhang D.L. Microstructural stability, phase transformation and mechanical properties of a fully-lamellar microstructure of a Mo-modified high-Nb γ-TiAl alloy. Materials Science and Engineering: A. 2020;784:139313. https://doi.org/10.1016/j.msea.2020.139313

4. Kartavykh A.V., Tcherdyntsev V.V., Gorshenkov M.V., Kaloshkin S.D. Microstructure engineering of TiAl-based refractory intermetallics within power-down directional solidification process. Journal of Alloys and Compounds. 2014;586:180–183. https://doi.org/10.1016/j.jallcom.2012.10.175

5. Rittinghaus S.K., Zielinski J. Influence of process conditions on the local solidification and microstructure during laser metal deposition of an intermetallic TiAl alloy (GE4822). Metallurgical and Materials Transactions: A. 2021;52(3):1106–1116. https://doi.org/10.1007/s11661-021-06139-2

6. Zhang S.Z., Zhang C.J., Du Z.X., Hou Z.P., Lin P., Kong F.T., Chen Y.Y. Deformation behavior of high Nb containing TiAl based alloy in α + γ two phase field region. Materials & Design. 2016;90:225–229. https://doi.org/10.1016/j.matdes.2015.10.080

7. Nazarova T.I., Imayev V.M., Imayev R.M., Fecht H.J. Study of microstructure and mechanical properties of Ti–45Al–(Fe,Nb) (at.%) alloys. Intermetallics. 2017;82: 26–31. https://doi.org/10.1016/j.intermet.2016.11.009

8. Knörlein J., Franke M.M., Schloffer M., Berger T., Körner C. Microstructure and mechanical properties of additively manufactured γ-TiAl with dual microstructure. Intermetallics. 2023;161:107978. https://doi.org/10.1016/j.intermet.2023.107978

9. Imayev V., Gaisin R., Rudskoy A., Nazarova T., Shaimardanov R., Imayev R. Extraordinary superplastic properties of hot worked Ti–45Al–8Nb–0.2C alloy. Journal of Alloys and Compounds. 2016; 663:217–224. https://doi.org/10.1016/j.jallcom.2015.11.228

10. Taguchi K., Ayada M., Ishihara K.N., Shingu P.H. Near-net shape processing of TiAl intermetallic compounds via pseudoHIP-SHS route. Intermetallics. 1995;3(2):91–98. https://doi.org/10.1016/0966-9795(95)92673-N

11. Busurina M.L., Umarov L.M., Kovalev I.D., Sachkova N.V., Busurin S.M., Vadchenko S.G., Sychev A.E. Features of structure and phase formation in the Ti–Al–Nb system in the thermal explosion mode. Combustion, Explosion and Shock Waves. 2016;52(6):659–664. https://doi.org/10.15372/FGV20160605

12. Ismaeel A., Wang C. Effect of Nb additions on microstructure and properties of γ-TiAl based alloys fabricated by selective laser melting. Transactions of Nonferrous Metals Society of China. 2019;29(5):1007–1016. https://doi.org/10.1016/S1003-6326(19)65009-0

13. Glenn E.B., Ebrahimi F., Manuel M.V. High temperature deformation of Ti–Al–Nb–Cr–Mo alloy with ultrafine microstructure. Intermetallics. 2014;49:132–137. https://doi.org/10.1016/j.intermet.2014.01.013

14. Loginov P.A., Kaplanskii Y.Y., Markov G.M., Patsera E.I., Vorotilo K.V., Korotitskiy A.V., Shvyndina N.V., Levashov E.A. Structural and mechanical properties of Ti–Al–Nb–Mo–B alloy produced from the SHS powder subjected to high-energy ball milling. Materials Science and Engineering: A. 2021;814:141153. https://doi.org/10.1016/j.msea.2021.141153

15. Loginov P.A., Markov G.M., Korotitskiy A.V., Levashov E.A. Compressive creep behavior of powder metallurgy manufactured Y2O3-reinforced TNM-B1 TiAl alloy with equiaxed and lamellar microstructure. Materials Characterization. 2023;205:113367. https://doi.org/10.1016/j.matchar.2023.113367

16. Polozov I., Razumov N., Makhmutov T., Silin A., Kim A., Popovich A. Synthesis of titanium orthorhombic alloy spherical powders by mechanical alloying and plasma spheroidization processes. Materials Letters. 2019;256:126615. https://doi.org/10.1016/j.matlet.2019.126615

17. Tong B., Lu X., Liu C.C., Wang L.N., Qu X.H. Fabrication of micro-fine spherical high Nb containing TiAl alloy powder based on reaction synthesis and RF plasma spheroidization. Powder Technology. 2015;283:9–15. https://doi.org/10.1016/j.powtec.2015.04.062

18. Yang W., Li M., Su S., Xiao S., Chen Y. Effects of carbon addition on the microstructure and mechanical property of in-situ reinforced TiAl matrix composite powders produced by plasma rotating electrode process. Journal of Materials Research and Technology. 2023;27:5204–5218. https://doi.org/10.1016/j.jmrt.2023.10.318

19. Polozov I., Sufiiarov V., Kantyukov A., Razumov N., Goncharov I., Makhmutov T., Silin A., Kim A., Starikov K., Shamshurin A. Microstructure, densification, and mechanical properties of titanium intermetallic alloy manufactured by laser powder bed fusion additive manufacturing with high-temperature preheating using gas atomized and mechanically alloyed plasma spheroidized powder. Additive Manufacturing. 2020;34:101374. https://doi.org/10.1016/J.ADDMA.2020.101374

20. Tsvetkov Y.V., Samokhin A.V., Alekseev N.V., Fadeev A.A., Sinaiskii M.A., Levashov E.A., Kaplanskii Y.Y. Plasma spheroidization of micropowders of a heat-resistant alloy based on nickel monoaluminide. Doklady Chemistry. 2018; 483:312–317. https://doi.org/10.1134/S0012500818120030

21. Sista K.S., Moon A.P., Sinha G.R., Pirjade B.M., Dwarapudi S. Spherical metal powders through RF plasma spherodization. Powder Technology. 2022;400:117225. https://doi.org/10.1016/j.powtec.2022.117225

22. Li Q., Zhang L., Wei D., Ren S., Qu X. Porous Nb-Ti based alloy produced from plasma spheroidized powder. Results in Physics. 2017; 7:1289–1298. https://doi.org/10.1016/j.rinp.2017.03.026

23. Sheng Y.W., Guo Z.M., Hao J.J. Yang D.H. Effect of spheroidization of Ti–6Al–4V powder on characteristics and rheological behaviors of gelcasting slurry. Procedia Engineering. 2012;36:299–306. https://doi.org/10.1016/j.proeng.2012.03.044

24. Kenel C., Leinenbach C. Influence of Nb and Mo on microstructure formation of rapidly solidified ternary Ti–Al–(Nb, Mo) alloys. Intermetallics. 2016;69:82–89. https://doi.org/10.1016/j.intermet.2015.10.018

25. Zhang S.Z., Song Z.W., Han J.C., Zhang C.J., Lin P., Zhu D.D., Kong F.T., Chen Y.Y. Effect of 2–6 at.% Mo addition on microstructural evolution of Ti–44Al alloy. Journal of Materials Science & Technology. 2018;34(7):1196–1204. https://doi.org/10.1016/j.jmst.2017.10.012

26. Zhou Y.H., Li W.P., Zhang L., Zhou S.Y., Jia X., Wang D.W., Yan M. Selective laser melting of Ti–22Al–25Nb intermetallic: Significant effects of hatch distance on microstructural features and mechanical properties. Journal of Materials Processing Technology. 2020;276:116398. https://doi.org/10.1016/j.jmatprotec.2019.116398

27. Polozov I., Gracheva A., Popovich A. Processing, microstructure, and mechanical properties of laser additive manufactured Ti2AlNb-based alloy with carbon, boron, and yttrium microalloying. Metals. 2022;12(8):1304. https://doi.org/10.3390/met12081304

28. Samokhin A.V., Fadeev A.A., Kirpichev D.E., Alekseev N.V., Berestenko V.I., Astashov A.G., Zavertyaev I.D. Plasma installation for spheroidization of metal powders in a thermal plasma flow. RF Patent № RU2756327C1 (RF). 2021.

29. Yang G., Xu X., Sun T., Xu S., Gui W., Zeng J., Mu Y., Liang Y., Lin J. A refined fully lamellar TiAl alloy extruded at α-phase region: Microstructure and mechanical properties. Materials Science and Engineering: A. 2023;888:145804. https://doi.org/10.1016/j.msea.2023.145804

30. Weisheit A., Rittinghaus S.K., Dutta A., Majumdar J.D. Studies on the effect of composition and pre-heating on microstructure and mechanical properties of direct laser clad titanium aluminide. Optics and Lasers in Engineering. 2020:131:106041. https://doi.org/10.1016/j.optlaseng.2020.106041

About the Authors

G. M. MarkovRussian Federation

Georgy M. Markov – Junior Research Scientist of the Laboratory “In situ Diagnostics of Structural Transformations” of ScientificEducational Center of Self Propagating High Temperature Synthesis (SHS-Center) of MISIS–ISMAN

4 Bld. 1 Leninskiy Prosp., Moscow 119049, Russia

A. A. Fadeev

Russian Federation

Andrey A. Fadeev – Cand. Sci. (Eng.), Senior Research Scientist of the Laboratory “Plasma Processes in Metallurgy and Materials Processing“ of Baikov Institute of Metallurgy and Materials Science of RAS; Scientific Project Engineer of NUST MISIS

4 Bld. 1 Leninskiy Prosp., Moscow 119049, Russia

49 Leninskiу Prosp., Moscow 119334, Russia

A. A. Skirpichnikova

Russian Federation

Anastasia A. Skirpichnikova – Research Assistant of SHS-Center of MISIS–ISMAN

4 Bld. 1 Leninskiy Prosp., Moscow 119049, Russia

P. A. Loginov

Russian Federation

Pavel A. Loginov – Cand. Sci. (Eng.), Senior Lecturer of the Department of Powder Metallurgy and Functional Coatings (PM&FC) of NUST MISIS; Senior Research Scientist of the Laboratory “In situ Diagnostics of Structural Transformations” of SHS-Center of MISIS–ISMAN

4 Bld. 1 Leninskiy Prosp., Moscow 119049, Russia

M. G. Khomutov

Russian Federation

Maxim G. Khomutov – Cand. Sci. (Eng.), Senior Research Scientist of the Laboratory of hybrid additive technologies

4 Bld. 1 Leninskiy Prosp., Moscow 119049, Russia

A. V. Samokhin

Russian Federation

Andrey V. Samokhin – Cand. Sci. (Eng.), Lead Research Scientist, Head of the Laboratory “Plasma Processes in Metallurgy and Materials Processing“

49 Leninskiу Prosp., Moscow 119334, Russia

E. A. Levashov

Russian Federation

Evgeny A. Levashov – Dr. Sci. (Eng.), Prof., Academic of the Russian Academy of Natural Science, Head of the Department of PM&FC of NUST MISIS; Head of SHS-Center of MISIS–ISMAN

4 Bld. 1 Leninskiy Prosp., Moscow 119049, Russia

Review

For citations:

Markov G.M., Fadeev A.A., Skirpichnikova A.A., Loginov P.A., Khomutov M.G., Samokhin A.V., Levashov E.A. Structural characteristics and mechanical properties of heat-resistant TNM-B1 alloy obtained by selective laser melting from SHS powder spheroidized in thermal plasma. Powder Metallurgy аnd Functional Coatings (Izvestiya Vuzov. Poroshkovaya Metallurgiya i Funktsional'nye Pokrytiya). 2024;18(4):69-82. https://doi.org/10.17073/1997-308X-2024-4-69-82