Scroll to:

Erosion resistance of ZrBN protective coatings deposited by reactive pulsed magnetron sputtering

https://doi.org/10.17073/1997-308X-2024-5-37-43

Abstract

ZrBN coatings were deposited by reactive pulsed magnetron sputtering using a ZrB2 target while varying the pulse duration. The composition and structure of the coatings were studied using scanning and transmission electron microscopy, energy dispersive, optical emission and glow discharge Raman spectroscopy, as well as X-ray diffraction. Optical properties were studied by spectrophotometry. Erosion resistance was determined under laser exposure. All coatings were amorphous, had a dense, defect-free structure and a uniform distribution of elements throughout the thickness. According to Raman spectroscopy, the coatings contain B–N and Zr–N bonds. The coatings were characterized by high optical transmittance of 70–90 % in the wavelength range 450–1300 nm. The reflectivity of coatings was 9–26 %. The refractive index value increases from 1.7 to 3.0 as the wavelength increases from 200 to 1200 nm. The glass substrate is fragilely destroyed during erosion at a power of 20–60 W. All coatings successfully protect the glass substrate from erosive wear: the application of ZrBN coatings leads to a reduction in the width and depth of the erosion zone of the glass substrate by 1.3 and 4.5 times, respectively. The coating obtained at the optimal pulse duration has better erosion resistance, which may be due to its higher adhesive strength.

For citations:

Chertova A.D., Levanov A.V., Meshkov B.B., Levashov E.A., Kiryukhantsev-Korneev P.V. Erosion resistance of ZrBN protective coatings deposited by reactive pulsed magnetron sputtering. Powder Metallurgy аnd Functional Coatings (Izvestiya Vuzov. Poroshkovaya Metallurgiya i Funktsional'nye Pokrytiya). 2024;18(5):37-43. https://doi.org/10.17073/1997-308X-2024-5-37-43

Introduction

One of the current challenges in the operation of optical equipment components (such as lenses, prisms, mirrors, interferometers, etc.) is wear due to erosion, which significantly affects their service life. Therefore, the development of optical coatings is an important direction in the creation of new precision optical devices [1]. These coatings must not only exhibit high transmittance and good reflectivity but also enhanced erosion resistance [2].

To protect optical device components exposed to wear, oxide coatings such as ZrO2 , Ta2O5 , and others are commonly used. These coatings possess a wide transparent spectral range and high refractive indices [3; 4]. However, oxide coatings are characterized by relatively low hardness: 7 GPa for Nb2O5 [5], 8 GPa for TiO2 [6], 10 GPa for SiO2 [7], and 13 GPa for In2O3 [8]. They also show poor scratch resistance and have a high defect density in their structure, negatively impacting their wear resistance [9]. Recently, there has been growing interest in the study of transition metal nitrides, such as Ti, Zr, Cr, Nb, Mo, and Ta, which offer satisfactory optical properties combined with good wear resistance [10]. Comparative studies of TiN and TiAlN hard coatings have demonstrated that aluminum alloying enhances wear resistance under thermal stress conditions [11]. Among TiN, HfN, and ZrN coatings, zirconium nitride coatings exhibit superior optical properties [12]. Introducing boron into ZrN coatings can improve hardness, wear resistance, and optical characteristics.

Previously, we developed wear-resistant ZrBN coatings with high thermal stability and an optical transmittance of up to 90 % [13], which was associated with a high volume fraction of the BN phase. We established the influence of pulse frequency and duration during the deposition of ZrBN coatings using pulsed magnetron sputtering (PMS) on their structure, optical properties, hardness, elastic-plastic characteristics, and wear resistance under friction, sliding, and abrasive conditions [14; 15]. However, the protective properties of ZrBN coatings under erosion conditions require further investigation. It is important to note that ZrBN coatings serve as an excellent model composition, which can serve as the basis for developing more complex multicomponent structures based on advanced heterophase ceramics in the future [16].

The aim of this study is to investigate the structure, optical properties, and erosion resistance of ZrBN coatings deposited by PMS.

Materials and methods

Zr–B–N coatings were deposited using reactive pulsed magnetron sputtering (PMS) with a ZrB2 target. The deposition was performed using a setup based on the UVN-2M vacuum system, the schematic of which is described in [17]. Nitrogen (99.999 % purity) was used as the working gas, with a pressure of 0.1–0.2 Pa.

The magnetron was powered by a Pinnacle Plus 5×5 unit (Advanced Energy, USA), with a power output of 1 kW, a current of 2 A, and a voltage in the range of 400–500 V. The frequency was set at 350 kHz, and the pulse durations were 0.4 μs (coating 1), 0.7 μs (coating 2), and 1.1 μs (coating 3). The sputtering process lasted for 40 min.

Colorless optical glass plates (K8) were used as substrates. Before coating deposition, the substrates were cleaned in an ultrasonic bath for 5 min in isopropyl alcohol. Ion cleaning of the substrates was performed using an Ar\(^+\) on beam from a slit-type ion source at an accelerating voltage of 2.5 kV for 20 min. The coating deposition time was 40 min.

The structural analysis of the coatings was conducted using scanning electron microscopy (SEM) and energy-dispersive spectroscopy (EDS) on a Hitachi S-3400N microscope equipped with a NORAN 7 Thermo system. Transmission electron microscopy (TEM) was performed on a JEM-2100 microscope (Jeol). Glow discharge optical emission spectrometry (GD-OES) was carried out using the PROFILER-2 system (Horiba Jobin Yvon) [18]. TEM samples were prepared by ion milling using a PIPS II dual-beam precision ion polishing system (Gatan Inc., USA). Raman spectra were obtained with a LabRam HR800 system (Horiba JY) equipped with a 514 nm green laser source. X-ray phase analysis (XRD) was conducted using CuKα radiation (λ = 0.154 nm) on a Phaser D2 diffractometer (Bruker). Optical properties were measured over a wavelength range of 380–1300 nm using a Photon-RT spectrophotometer.

The erosion resistance of the coatings was tested on a LaserPRO Spirit laboratory setup. The CO2 laser power was set at 20, 40, and 60 W. The length of the laser track and exposure time were 10 mm and 2 s, respectively. The tracks were examined using an Axiovert 25 optical microscope (Carl Zeiss) and a WYKO-NT1100 optical profilometer (Veeco).

Results and discussion

All elements in the coatings were uniformly distributed throughout their depth, with impurity levels (C and O) ranging from 0.7 to 1.8 at. %. The coatings, regardless of pulse duration, had a similar elemental composition, at. %: 14 ± 2 Zr, 46 ± 2 B, and 40 ± 2 N. The thickness and growth rate of the coatings were 1.3–1.5 μm and 32–39 nm/min, respectively. The Zr–B–N coatings exhibited a dense, homogeneous structure without the characteristic columnar elements typical of nitrogen-containing ion-plasma coatings [19].

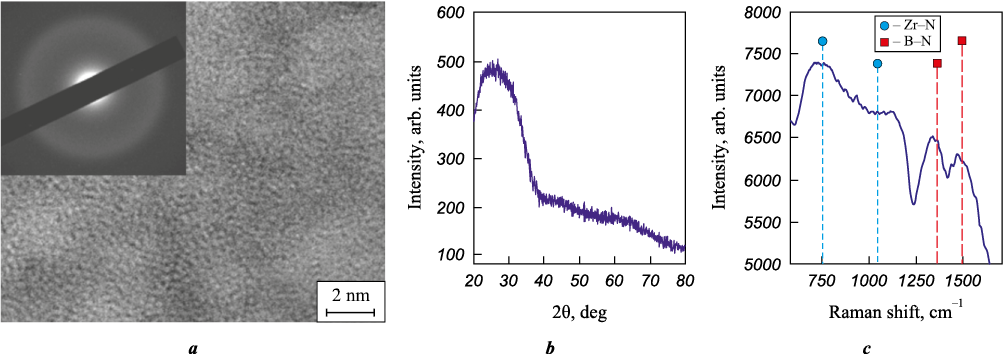

Fig. 1 shows a typical electron diffraction pattern, a bright-field image of the structure, an X-ray diffraction pattern, and a Raman scattering spectrum for coating 2.

Fig. 1. BF TEM image, SAED (a), XRD pattern (b), and Raman spectra (c) for coating 2 |

The electron diffraction pattern (Fig. 1, a) shows a broad ring, indicating the presence of an amorphous phase. The X-ray diffraction pattern (Fig. 1, b) displays a halo in the 2θ = 20÷40° range, further confirming the amorphous nature of the coatings. Raman spectroscopy (Fig. 1, c) was used to clarify the phase composition of the coatings. The spectrum shows pronounced peaks at 1360 and 1490 cm\(^–\)1, which can be attributed to the BN phase [20]. In the 600–1200 cm\(^–\)1 wavelength range, peaks corresponding to the ZrN phase are observed.

Fig. 2, a and b present the spectral-angular dependencies of the transmittance (T) and reflectance (R) coefficients as a function of wavelength (λ) for coating 2. The T and R spectra exhibit an oscillatory character, which is associated with interference effects. The ZrBN coatings showed a transmittance of 70÷87 % in the 450–1300 nm wavelength range (Fig. 2, a). At the same time, the R values ranged from 9 to 26 %, depending on the wavelength. It is worth noting that the transmittance of ZrBN coatings is comparable to that of traditional oxide coatings such as Zr–O, Zr–Al–O, and ZrSiN nitride-based coatings (Т = 70÷90 %) [22; 23].

Fig. 2. Transmittance (a), reflection (b), and the refractive index (c) of coating 2 |

The interference nature of the transmittance and reflectance curves allowed the determination of the dispersion dependence of the refractive index (n) (Fig. 2, c). As the wavelength increased from 400 to 900 nm, the refractive index gradually decreased from 2.29 to 2.06, indicating strong absorption of visible light due to free electrons and weaker absorption of infrared radiation. It is worth noting that ZrN coatings exhibit weaker visible light absorption, with the refractive index increasing from 1.7 to 3.0 as the wavelength increases from 200 to 1200 nm [19].

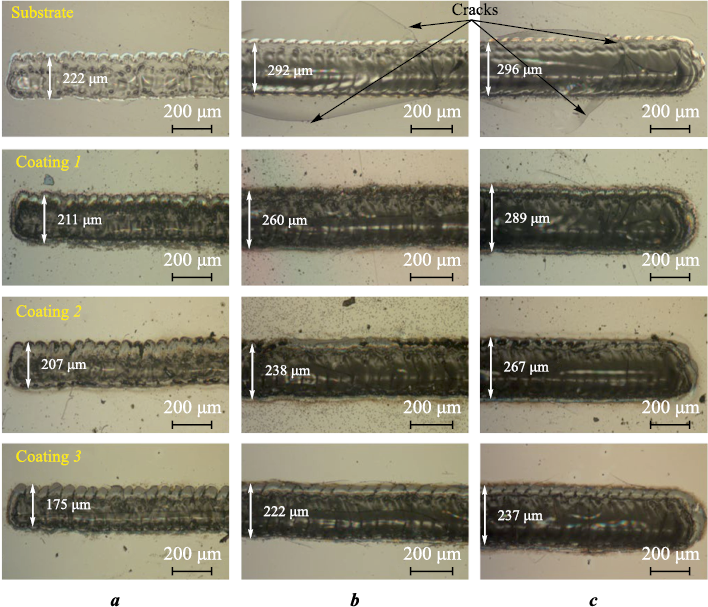

SEM images of the surface of the uncoated substrate and coatings 1–3 after erosion exposure at 20 W power are shown in Fig. 3, a. The track width for the uncoated substrate was 222 μm. The application of coatings 1, 2, and 3 reduced the track width by 5, 7, and 21 %, respectively. At increased powers of 40 and 60 W (Figs. 3, b and c), the uncoated substrate exhibited crack formation and chipping along the track boundaries, whereas no cracks or delamination were observed in the coatings tested under the same conditions. Coating 3 had the smallest track width, measuring 222 and 237 μm at powers of 40 and 60 W, respectively, while the substrate had values of 292 and 296 μm (Fig. 3).

Fig. 3. SEM-images of tracks after erosion test for uncoated substrate |

Thus, the application of coating 3 reduced the track width by 1.3 times compared to the uncoated glass substrate.

The tracks after erosion exposure were also analyzed using optical profilometry, with the most prominent results shown in Fig. 4. The two-dimensional profiles reveal that the uncoated glass substrate is unevenly damaged. More intense material degradation occurs at the final moment of scanning (Fig. 4, a, marked by an arrow). This effect may be due to the increased brittleness, low thermal stability, and low thermal conductivity of the glass substrate. The maximum depth at the center of the track was ~9 μm (Fig. 4, a).

Fig. 4. 3D and 2D track profiles after erosion test for uncoated substrate (a) and coating 3 (b) |

For the ZrBN coatings, as exemplified by sample 3 (Fig. 4, b), no brittle fracture was observed, and the track was uniform.

The maximum track depth at the center for all coatings was around 2 μm, which is 4.5 times lower than the values obtained for the uncoated glass substrate.

Thus, all coatings successfully protect the glass substrate from erosion. Coating 3 demonstrated the best resistance, likely due to its higher crack resistance and adhesion strength [15].

Conclusion

Amorphous ZrBN coatings with a thickness of 1.3–1.5 μm were deposited using pulsed magnetron sputtering with varying pulse durations. The coatings exhibited a dense, homogeneous structure. The transmittance and reflectance coefficients in the 450–1300 nm wavelength range were 70–87 % and 9–26 %, respectively. The refractive index ranged from 2.29 to 2.06 in the λ = 400–900 nm range. Erosion resistance tests revealed that the glass substrate cracked and degraded significantly during the experiments. However, the application of ZrBN coatings prevented substrate cracking and reduced the width and depth of the erosion zone by 1.3 and 4.5 times, respectively.

References

1. Hu C., Guo K., Li Y., Gu Z., Quan J., Zhang S., Zheng W. Optical coatings of durability based on transition metal nitrides. Thin Solid Films. 2019;688:137339. https://doi.org/10.1016/j.tsf.2019.05.058

2. Mishra S.K., Kumar V., Tiwari S.K., Mishra T., Angula G., Adhikari S. Development and degradation behavior of protective multilayer coatings for aluminum reflectors for solar thermal applications. Thin Solid Films. 2016;619:202–207. https://doi.org/10.1016/j.tsf.2016.10.067

3. Zhu Y., Ma M., Zhang P., Cai W., Li D., Xu C. Preparation of sol-gel ZrO2 films with high laser-induced damage threshold under high temperature. Optics Express. 2019;27(26):37568–37578. https://doi.org/10.1364/OE.27.037568

4. Zhang P., Lin D., Zhu Y., Cai W., Li D., Xu C. In-situ high temperature laser-induced damage of sol-gel Ta2O5 films with different dual additives. Thin Solid Films. 2020;693:137723. https://doi.org/10.1016/j.tsf.2019.137723

5. Mazur M., Szymańska M., Kaczmarek D., Kalisz M., Wojcieszak D., Domaradzki J., Placido F. Determination of optical and mechanical properties of Nb2O5 thin films for solar cells application. Applied Surface Science. 2014;301:63–69. https://doi.org/10.1016/j.apsusc.2014.01.144

6. Krishna D.S.R., Sun Y., Chen Z. Magnetron sputtered TiO2 films on a stainless steel substrate: selective rutile phase formation and its tribological and anti-corrosion performance. Thin Solid Films. 2011;519(15):4860–4864. https://doi.org/10.1016/j.tsf.2011.01.042

7. Mazur M., Wojcieszak D., Kaczmarek D., Domaradzki J., Song S., Gibson D., Placido F., Mazur P., Kalisz M., Poniedzialek A. Functional photocatalytically active and scratch resistant antireflective coating based on TiO2 and SiO2 . Applied Surface Science. 2016;380:165–171. https://doi.org/10.1016/j.apsusc.2016.01.226

8. Yang L., Zhu J., Bai J., Zhu Y., Dai B., Yu H., Jia Z., Han J. Plasma exposure inducing crystallization of indium oxide film with improved electrical and mechanical properties at room temperature. Journal of Materials Science. 2014;49:5955–5960. https://doi.org/10.1007/S10853-014-8314-0

9. Fryauf D.M., Phillips A.C., Kobayashi N.P. Corrosion barriers for silver-based telescope mirrors: comparative study of plasma-enhanced atomic layer deposition and reactive evaporation of aluminum oxide. Journal of Astronomical Telescopes, Instruments, and Systems. 2015;1(4):044002. https://doi.org/10.1117/1.JATIS.1.4.044002

10. Gaković B.M., Trtica M., Nenadović T., Gredić T. Transversely excited atmospheric CO2 laser-induced damage of TiN and (Ti,Al)N coatings. Applied Surface Science. 1999;143(1-4):78–84. https://doi.org/10.1016/S0169-4332(98)00903-9

11. Jafari M., Rogström L., Andersson J.M., Birch J., Gibmeier J., Jöesaar M.J., Kiefer D., Odén M. Thermal degradation of TiN and TiAlN coatings during rapid laser treatment. Surface and Coatings Technology. 2021;422:127517. https://doi.org/10.1016/j.surfcoat.2021.127517

12. Patsalas P. Zirconium nitride: A viable candidate for photonics and plasmonics? Thin Solid Films. 2019;688:137438. https://doi.org/10.1016/j.tsf.2019.137438

13. Kiryukhantsev-Korneev P.V., Sytchenko A.D., Kozlova N.S., Zabelina E.V., Skryleva E.A., Kaplansky Y.Y., Vakhrushev R.A., Levashov E.A. Structure and properties of protective amorphous ZrBN coating. Surface and Coatings Technology. 2022;448:128849. https://doi.org/10.1016/j.surfcoat.2022.128849

14. Kiryukhantsev-Korneev P.V., Levashov E.A. Transparency effect in Zr−B−N coatings obtained by magnetron sputtering of ZrB2 target. Technical Physics Letters. 2020;46(2):179–181. https://doi.org/10.1134/S1063785020020224

15. Kiryukhantsev-Korneev P.V., Sytchenko A.D., Levashov E.A. The effect of pulse duration on the structure and mechanical, tribotechnical, and optical characteristics of Zr–B–N coatings obtained by the PMS method. Protection of Metals and Physical Chemistry of Surfaces. 2021;57(6):1222–1230. https://doi.org/10.1134/S2070205121060125

16. Houska J., Steidl P., Vlcek J., Martan J. Thermal, mechanical and electrical properties of hard B4C, BCN, ZrBC and ZrBCN ceramics. Ceramics International. 2016; 42(3):4361-4369. https://doi.org/10.1016/j.ceramint.2015.11.115

17. Kiryukhantsev-Korneev P.V., Sytchenko A.D., Sviridova T.A., Sidorenko D.A., Andreev N.V., Klechkovskaya V.V., Polčak J., Levashov E.A., Effects of doping with Zr and Hf on the structure and properties of Mo–Si–B coatings obtained by magnetron sputtering of composite targets. Surface and Coatings Technology. 2022;442: 128141. https://doi.org/10.1016/j.surfcoat.2022.128141

18. Kiryukhantsev-Korneev P.V. Elemental analysis of coatings by high-frequency glow discharge optical emission spectroscopy. Protection of Metals and Physical Chemistry of Surfaces. 2012;48(5):585–590. https://doi.org/10.1134/S207020511205005X

19. Pilloud D., Dehlinger A.S., Pierson J.F., Roman A., Pichon L. Reactively sputtered zirconium nitride coatings: structural, mechanical, optical and electrical characteristics. Surface and Coatings Technology. 2003; 174–175:338–344. https://doi.org/10.1016/S0257-8972(03)00613-3

20. Chang J., Zhang H., Cao J. Ultrahigh sensitive and selective triethylamine sensor based on h-BN modified MoO3 nanowires. Advanced Powder Technology. 2022;33(2): 103432. https://doi.org/10.1016/j.apt.2022.103432

21. Rizzo А., Valerini D., Capodieci L., Mirenghi L., Di Benedetto F., Protopapa M.L. Reactive bipolar pulsed dual magnetron sputtering of ZrN films: the effect of duty cycle. Applied Surface Science. 2018;427(A):994–1002. https://doi.org/10.1016/j.apsusc.2017.08.032

22. Musil J., Sklenka J., Cerstvy R. Transparent Zr–Al–O oxide coatings with enhanced resistance to cracking. Surface and Coatings Technology. 2012;206(8-9):2105–2109. https://doi.org/10.1016/j.surfcoat.2011.09.035

23. Pilloud D. Influence of the silicon concentration on the optical and electrical properties of reactively sputtered Zr–Si–N nanocomposite coatings. Materials Science and Engineering: B. 2006;131(1-3):36–39. https://doi.org/10.1016/j.mseb.2006.03.017

About the Authors

A. D. ChertovaRussian Federation

Alina D. Chertova – Cand. Sci. (Eng.), Junior Research Scientist of the Laboratory “In situ Diagnostics of Structural Transformations” of Scientific-Educational Center of Self-Propagating High-Temperature Synthesis (SHS-Center) MISIS–ISMAN, National University of Science and Technology “MISIS” (NUST “MISIS”)

1 Bld, 4 Leninskiy Prosp., Moscow 119049, Russia

A. V. Levanov

Russian Federation

Alexander V. Levanov – Cand. Sci. (Chem.), Associate Professor of the Department of Chemistry

4 Bld, 27 Lomonosovskiy Prosp., Moscow 119991, Russia

B. B. Meshkov

Russian Federation

Boris B. Meshkov – Cand. Sci. (Eng.), Head of the Optical Coatings Laboratory

5 Bld, 29 Krzhizhanovckiy Str., Moscow 117218, Russia

E. A. Levashov

Russian Federation

Evgeniy A. Levashov – Dr. Sci. (Eng.), Prof., Acad. of the Russian Academy of Natural Science, Head of the Department of Powder Metallurgy and Functional Coatings (PM&FC) NUST “MISIS”, Director of SHS-Center of MISIS–ISMAN

1 Bld, 4 Leninskiy Prosp., Moscow 119049, Russia

Ph. V. Kiryukhantsev-Korneev

Russian Federation

Philipp V. Kiryukhantsev-Korneev – Dr. Sci. (Eng.), Professor of the Department of PM&FC of NUST “MISIS”, Head of the Laboratory «In situ Diagnostics of Structural Transformations” of SHS-Center of MISIS–ISMAN

1 Bld, 4 Leninskiy Prosp., Moscow 119049, Russia

Review

For citations:

Chertova A.D., Levanov A.V., Meshkov B.B., Levashov E.A., Kiryukhantsev-Korneev P.V. Erosion resistance of ZrBN protective coatings deposited by reactive pulsed magnetron sputtering. Powder Metallurgy аnd Functional Coatings (Izvestiya Vuzov. Poroshkovaya Metallurgiya i Funktsional'nye Pokrytiya). 2024;18(5):37-43. https://doi.org/10.17073/1997-308X-2024-5-37-43

JATS XML