Scroll to:

Formation of wear-resistant coatings during electric arc surfacing with ultrasonic vibrations

https://doi.org/10.17073/1997-308X-2024-5-44-54

Abstract

The study focuses on investigating the influence of ultrasonic vibrations introduced into the crystallizing metal of the weld pool through filler wire during automated electric arc surfacing with flux-cored wire, on the formation characteristics of a wear-resistant coating made from the 280Cr14Mn6Ni6Mo3Ti2Nb2 alloy. The effect of ultrasonic vibrations on the structural-phase composition, hardness, and wear resistance of the surfaced coating is analyzed, particularly under normal and elevated temperatures up to 600 °C in conditions of exposure to a gas-abrasive flow. The failure pattern of the thin surface layers of the worn coatings is also studied. It was established that the microstructure of the coating consists of a carbide eutectic based on austenite, which possesses increased ductility and sufficiently high strength due to alloying with chromium and molybdenum. This ensures reliable retention of reinforcing phases represented by Мо2С, (Ti,Nb,Mo)xCy , and MexCy carbides. It is shown that under the influence of high-frequency acoustic vibrations, large primary MexCy carbides disappear from the alloy structure, the volume fraction of austenite increases by 25 %, and the proportion of MexCy-type carbides decreases. Additionally, a redistribution of alloying elements between the austenite and carbide phases is observed. The formation of a fine lamellar eutectic leads to changes in the wear mechanism of the alloy: hard solution layers dampen shear deformations caused by impacts of abrasive particles, while the plastic flow of the austenitic matrix forms a metallic binder around the broken carbide fragments, reducing the likelihood of their detachment. This results in an 18 % increase in the alloy’s resistance to high-temperature gas-abrasive wear, surpassing the performance of an international industrial counterpart.

Keywords

For citations:

Priyatkin D.V., Artem’ev A.A., Lysak V.I. Formation of wear-resistant coatings during electric arc surfacing with ultrasonic vibrations. Powder Metallurgy аnd Functional Coatings (Izvestiya Vuzov. Poroshkovaya Metallurgiya i Funktsional'nye Pokrytiya). 2024;18(5):44-54. https://doi.org/10.17073/1997-308X-2024-5-44-54

Introduction

Industrial equipment during operation is subjected to abrasive wear, which significantly reduces its service life by altering the size, shape, and condition of the working surfaces of parts [1; 2]. For instance, components of industrial fans, draft machines, solid-fuel boilers, and gas turbine units are exposed to abrasive particles carried by high-speed flows of heated gases. The need to replace wornout parts leads to substantial economic losses due to prolonged equipment downtime during repairs [2–4]. Extending the service life of parts can be achieved efficiently by strengthening their surface with wear-resistant alloys [4; 5].

One of the key kinematic parameters determining the nature and intensity of the wear surface destruction is the angle of its attack by the gas-abrasive flow [6; 7]. At small attack angles (20–30°) and temperatures up to 600 °C, typical for the operation of forced draft fans, the surface destruction mechanism is dominated by plastic displacement of the metal and microcutting, which leads to low wear resistance of ductile materials [8–10]. Under these conditions, alloys based on iron with a composite structure, consisting of both large and fine hard carbides distributed throughout a ductile matrix, are more preferable [11; 12].

The task of obtaining thick wear-resistant coatings on the surface of parts is most universally and effectively solved by electric arc surfacing with flux-cored wire [1; 13]. The use of flux-cored wire allows the production of coatings with virtually any chemical composition, providing them with the necessary operational properties [14; 15]. Dynamic exposure to ultrasonic vibrations (from 18 kHz) on the alloys crystallizing during the surfacing process is one of the known technological methods that allows altering their structural-phase composition, increasing wear resistance, reducing the likelihood of internal defects, and more [16–18]. These changes are caused by the formation of standing waves in the melt, characterized by alternating regions of compression and rarefaction. The generation of high energy densities in these regions manifests in secondary effects (cavitation, acoustic flows, radiation pressure, viscous friction forces), creating specific conditions for the crystallization of the metallic melt [19; 20]. These effects contribute to the intensification of physical and chemical processes: degassing, diffusion, metal structure dispersion, phase coagulation, and others [21; 22].

Among all known methods of transmitting ultrasonic vibrations (USV) to the crystallizing melt in the weld pool, using filler (waveguide) wire for this purpose is of the greatest practical interest [23]. In this case, it becomes possible to affect the melt near the crystallization front, where the acoustic treatment has the most noticeable effect. Using flux-cored wire as a waveguide allows for alloying, reinforcing, and modifying the surfaced metal with refractory particles, while the USV can contribute to their more uniform distribution within the melt [24; 25]. At the same time, it is necessary to note that the relationships between the influence of USV on the structure and properties of the surfaced wear-resistant alloys have not been fully explored in scientific and technical publications.

The objective of this study is to investigate the influence of USV on the structural-phase composition and resistance to gas-abrasive wear at temperatures up to 600 °C of a coating made from the experimental alloy 280Cr14Mn6Ni6Mo3Ti2Nb2, surfaced by the electric arc method.

Materials and methods

During the formation of the wear-resistant coating by electric arc surfacing in a protective gas, an experimental flux-cored wire (FCW) with a diameter of 2.8 mm was used as the electrode. A strip of 08kp steel (low-carbon killed steel, ~0.08 % C) with a thickness of 0.25 mm was used as the sheath for the FCW, and the filler material of the wire consisted of metallic powders of chromium, nickel, molybdenum, niobium, titanium, iron, as well as graphite powder. The composition of the filler was calculated to achieve a eutectic structure in the surfaced alloy, featuring a tough and ductile austenitic matrix stabilized by carbon, nickel, and manganese, capable of securely retaining hard phases in the form of chromium, titanium, niobium, and molybdenum carbides [26].

A wear-resistant coating was formed in a single layer of 6–7 mm thickness on the surface of plates made of St3sp steel, with the following chemical composition (wt. %:

| C . . . . . . . . . . . 2.7–2.9 |

| Cr . . . . . . . . . . 13.5–15.0 |

| Ni . . . . . . . . . . 5.7–6.0 |

| Mn . . . . . . . . . 6.0–6.2 |

| Mo . . . . . . . . . . 3.0–3.14 |

| Nb . . . . . . . . . . 2.0–2.1 |

| Ti . . . . . . . . . . . 2.0–2.15 |

| Fe . . . . . . . . . . . balance |

To protect the molten metal from atmospheric exposure, gaseous argon was used. For comparison of the wear resistance of the experimental coating with industrial counterparts, samples from the 600Cr23B7Mo7Si2W2F alloy were produced by electric arc surfacing using covered Weartrode 65T electrodes (ESAB.

As the filler (waveguide) wire, a flux-cored wire with a diameter of 2 mm was used, made with a steel strip sheath 0.5 mm thick and filled with iron powder.

The chemical composition of the surfaced coating was determined using an optical emission spectrometer Oxford Instruments PMI-MASTER PRO. Metallographic studies were carried out using optical (Carl Zeiss Axiovert 40 MAT microscope) and electron microscopy (FEI Versa 3D scanning electron-ion microscope). Metallographic sections were prepared using a grinding machine MP-1B Time Group Inc.

X-ray microanalysis of the structural components of the coating and elemental mapping of the alloying elements on the surface of microsections was carried out using an energy-dispersive X-ray detector (Apollo X-SDD) mounted on a Versa 3D microscope. The volumetric fractions of the structural components in the coating were determined by analyzing the elemental distribution maps on the microsection surface using the Image J software, by calculating the area occupied by each component.

X-ray phase analysis of the surfaced coatings was performed using a “Bruker D8 Advance Eco” X-ray diffractometer with a vertical θ-θ goniometer. The samples were scanned using copper anode radiation (λ = 1.54060 Å) under the following conditions: X-ray tube voltage – 40 kV; filament current – 25 mA; exposure time – 1 s; scanning step – 0.02°. Phase identification in the coatings was carried out using Diffrac.EVA software equipped with the licensed “Powder Diffraction File-2” database (The International Center for Diffraction Data).

Hardness testing of the surfaced coating was conducted by the Rockwell method (scale C) using a “TN-500 Time Group Inc.” hardness tester.

The resistance of the surfaced coating to gas-abrasive wear at normal and elevated temperatures up to 600 °C was evaluated using an express testing method described in [27]. The coating sample, a plate measuring 40×16×3.5 mm, was heated by passing an electric current through it and subjected to a stream of heated compressed air mixed with abrasive particles of quartz sand with an average size of 260 µm. Stability of the testing temperature was ensured by controlling the sample temperature with a WR5/20 thermocouple, connected to an LA-20 USB analog-to-digital converter, which displayed the readings on a computer screen using “PowerGraph” software. The test parameters were as follows: test duration – 120 s, air pressure in the system – 3 atm, attack angle of the gas-abrasive stream on the sample surface – 30°.

The wear resistance criterion was the specific wear rate (ξ, g/kg), calculated using the formula

ξ = ∆m/∆ma ,

where Δm is the mass loss of the tested sample, g; mа is the mass of abrasive used during the test, kg. The mass loss of the samples was measured with an accuracy of 0.0001 g using “Shinko Denshi VIBRA HT-124RCE” analytical scales.

The plastic deformation characteristics of the thin surface layers of worn coatings were studied using an electron-ion microscope, by preparing microsections of the surface through ion etching, with a platinum layer applied beforehand.

Technique for forming surfaced coatings

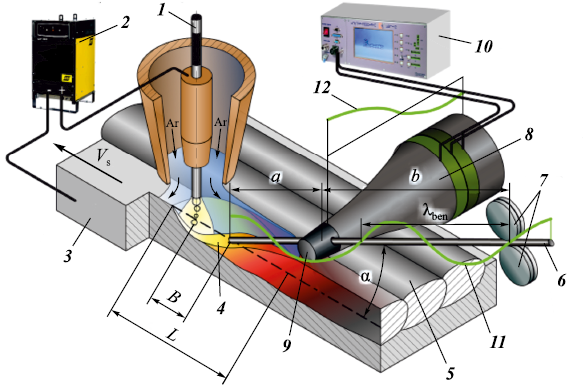

Electric arc surfacing of the coating (Fig. 1) using the experimental flux-cored wire (FCW) was performed with the “A2 Mini Master” (ESAB) welding machine, equipped with a device for introducing ultrasonic vibrations (USV) into the weld pool via a waveguide wire.

Fig. 1. Schematic diagram of the formation of the surfaced coating with the influence of USV |

In the electro-neutral waveguide wire, which is constantly immersed in the weld pool and fed into it at a constant speed, bending vibrations with a frequency of 20.6 kHz are generated by an ultrasonic piezoelectric transducer performing longitudinal vibrations. The wire melts due to the heat generated in the welding reaction zone and also from the heat generated within the wire itself as it transmits the USV [28]. To achieve the maximum vibration amplitude at the end of the waveguide wire in the weld pool, its extension (a) must be a multiple of half the wavelength of the bending waves (λben ), and the rollers of the feeding mechanism must contact the wire at a vibration node at a distance (b) from the end of the transducer (Fig. 1). This helps reduce energy losses during the surfacing process, as the system becomes acoustically closed.

The power source for the ultrasonic transducer was the ultrasonic generator UZG 4-2, manufactured by Ultra-resonance (Ekaterinburg). The electrical power consumed by the transducer during surfacing was 200 W. Amplitude and frequency of acoustic vibrations were monitored using non-contact laser vibrometry with the “Polytec VibroFlex Neo” vibrometer.

Surfacing was performed on steel plates measuring 200×150×12 mm with an overlap of weld beads equal to 30 % of their width. To prevent cracks in the surfaced coating, the plates were preheated to a temperature of 300 ± 20 °C and allowed to cool slowly after surfacing. The pre-surfacing temperature was monitored using a TEKHNOAS S-20.4 infrared pyrometer.

The welding current source (direct current, electrode positive) was the thyristor rectifier ESAB LAF 1001. The technological and acoustic parameters of the surfacing process (see Table) were selected experimentally to ensure the formation of a well-shaped, defect-free surfaced coating with minimal penetration into the base metal. The main parameters of the surfacing process with and without ultrasonic vibrations did not differ.

Surfacing process parameters

|

The distance (B) between the electrode wire and the filler wire, which depends on the length of the weld pool (L), is one of the most important technological parameters of this process. It affects the quality of the surfaced coating formation, the uniform melting of the filler wire, and the stability of the ultrasonic treatment of the weld pool. When using waveguide FCW with a diameter of 2 mm and a feed rate of 28–29 m/h into the weld pool, the distance B should be within 0.37–0.57 of the pool length L [28]. Introducing the wire into the pool beyond the upper limit of this range results in defects in the surfaced coating, while introducing it too close to the electric arc makes ultrasonic treatment impossible, as the waveguide wire melts above the weld pool.

Introducing the wire into the weld pool at a 30° angle to the surfaced surface ensures complete melting of the wire over a wide range of feed speeds.

Results and discussion

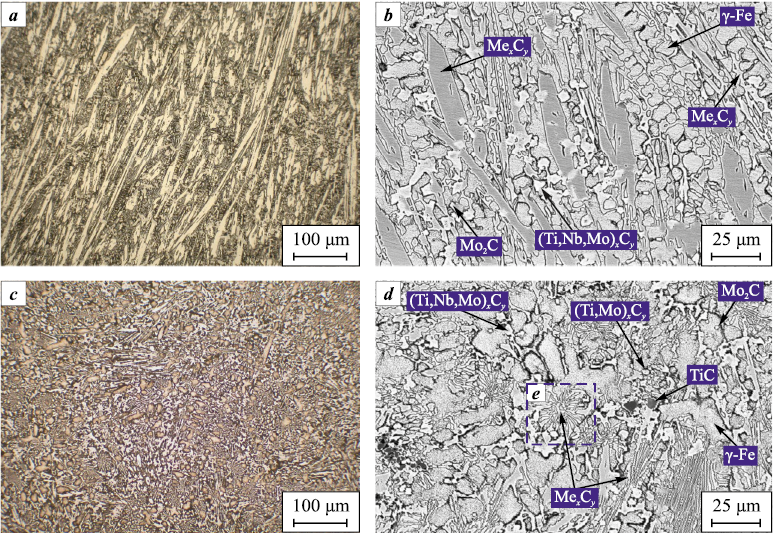

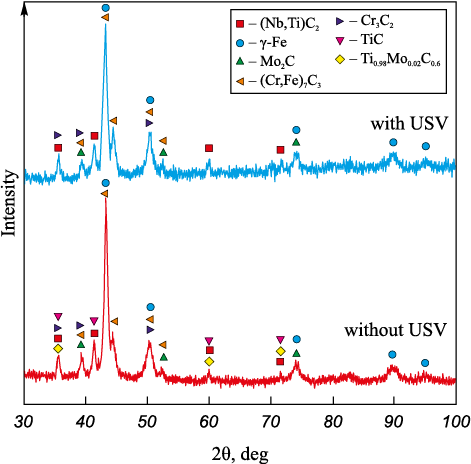

It was experimentally established that the influence of USV during the surfacing of the 280Cr14Mn6Ni6Mo3Ti2Nb2 alloy coating leads to significant structural changes (Fig. 2). The microstructure of the coating formed without acoustic treatment of the crystallizing alloy is hypereutectic, with large primary carbides of needle-like and plate-like shapes (Fig. 2, a, b). Combined X-ray microanalysis and X-ray phase analysis of the coatings showed that the solid solution of the carbide eutectic consists of alloyed γ-Fe, and the majority of the strengthening phase is represented by Me7C3 and Me3C2 carbides, where Me is chromium, iron, manganese, and molybdenum (Fig. 3). The structure also contains relatively uniformly distributed fine solid phases, represented by complex carbides (Ti,Nb,Mo)xCy and monocarbides Мо2С with an average particle size of 3.5 µm and 1.6 µm, respectively. No defects such as cracks, delamination from the base metal, pores, etc., were detected in the surfaced coating.

Fig. 2. Microstructure of the coating surfaced without USV (а, b) and with USV (c, d):

Fig. 3. Results of X-ray phase analysis of coatings surfaced |

The influence of high-frequency acoustic vibrations leads to the disappearance of large primary MexCy carbide crystals in the coating structure and some dispersion of the austenite-carbide eutectic (Fig. 2, c, d). This is accompanied by the appearance of characteristic “rosettes” consisting of plate-like carbides separated by layers of solid solution. In addition to the (Ti,Nb,Mo)xCy and Мо2С carbides, a small amount of (Ti,Mo)xCy and TiC carbides also appears in the alloy.

It has been established that high-frequency vibrations of the filler wire lead to its additional heating. This helps to reduce the “chilling” effect of the weld pool, which manifests in classical surfacing processes with “cold” filler by reducing its length. In the studied process, with a wire feed rate of 28–29 m/h, the pool length decreases by no more than 4 %. At the same time, the proportion of filler metal in the surfaced coating is very small, amounting to 1.0–1.2 wt. %. Thus, the changes in the structure of the studied alloy are related specifically to the influence of acoustic vibrations on the crystallization process, rather than to supercooling of the weld pool or changes in its chemical composition.

The mechanism of microstructure transformation in the surfaced coating under the influence of USV is as follows. In the absence of acoustic vibrations, large primary MexСy carbides crystallize from the weld pool, with an austenite-carbide eutectic forming between them. When high-frequency acoustic vibrations are induced in the melt, the crystallization process occurs under the mechanical action of shock waves generated by cavitation in the melt, which destroy the growing carbide crystals. The resulting carbide fragments are carried by acoustic flows along the crystallization front and act as additional nucleation centers for further crystallization. The formation of strengthening phases on these fragments in the melt may be facilitated by reduced surface tension at the interphase boundaries under the influence of USV.

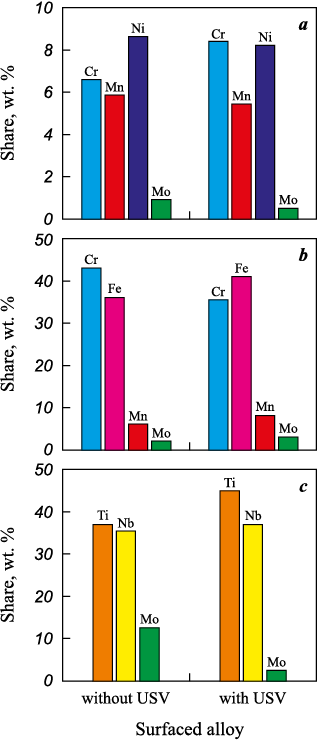

The change in the crystallization kinetics of the surfaced alloy due to acoustic treatment leads to a 25 % increase in the volume fraction of austenite (Fig. 4), while the content of MexСy carbides decreases proportionally, and the content of fine carbides (Ti,Nb,Mo)xСy and Mo2C changes insignificantly

Fig. 4. Volume fraction of structural components in the surfaced alloy with and without USV |

The change in the volume fraction of structural components in the surfaced alloy is accompanied by a redistribution of alloying elements between them (Fig. 5), which affects their mechanical properties. It was found that the molybdenum content in austenite decreases by a factor of two, while the chromium content increases by 20 %, which may improve the heat resistance of the alloy matrix. This is accompanied by a proportional decrease in the chromium content in MexCy carbides and an increase in the content of iron, manganese, and molybdenum, which may reduce their microhardness. The molybdenum content in (Ti,Nb,Mo)xCy carbides decreases almost fivefold, while the Ti/Nb ratio (in at. %) increases from 1.05 to 1.2, which, according to [29], may improve the microhardness of these carbides.

Fig. 5. Chemical composition of austenite (a), |

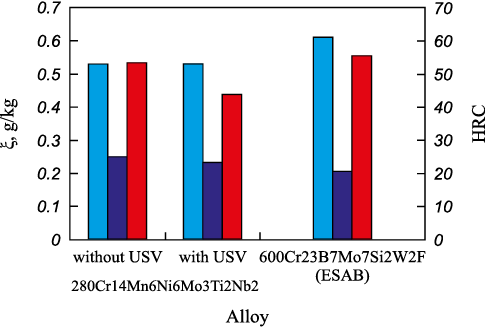

It has been established that the structural changes in the surfaced coating caused by USV do not affect its hardness, but they result in an average 18 % increase in its resistance to high-temperature gas-abrasive wear (Fig. 6). The wear resistance of the experimental alloy 280Cr14Mn6Ni6Mo3Ti2Nb2, modified by USV, exceeds that of the more heavily alloyed industrial counterpart 600Cr23B7Mo7Si2W2F (ESAB) by 26 %. The high wear resistance of the developed coating is due to the formation of a composite structure, combining a strong and ductile nickel-manganese austenitic matrix, alloyed with chromium and molybdenum, and a strengthening phase in the form of plate-like MexCy carbides and ultra-hard fine carbides (Ti,Nb,Mo)xCy and Мо2С.

Fig. 6. Hardness (HRC) and specific wear (ξ) |

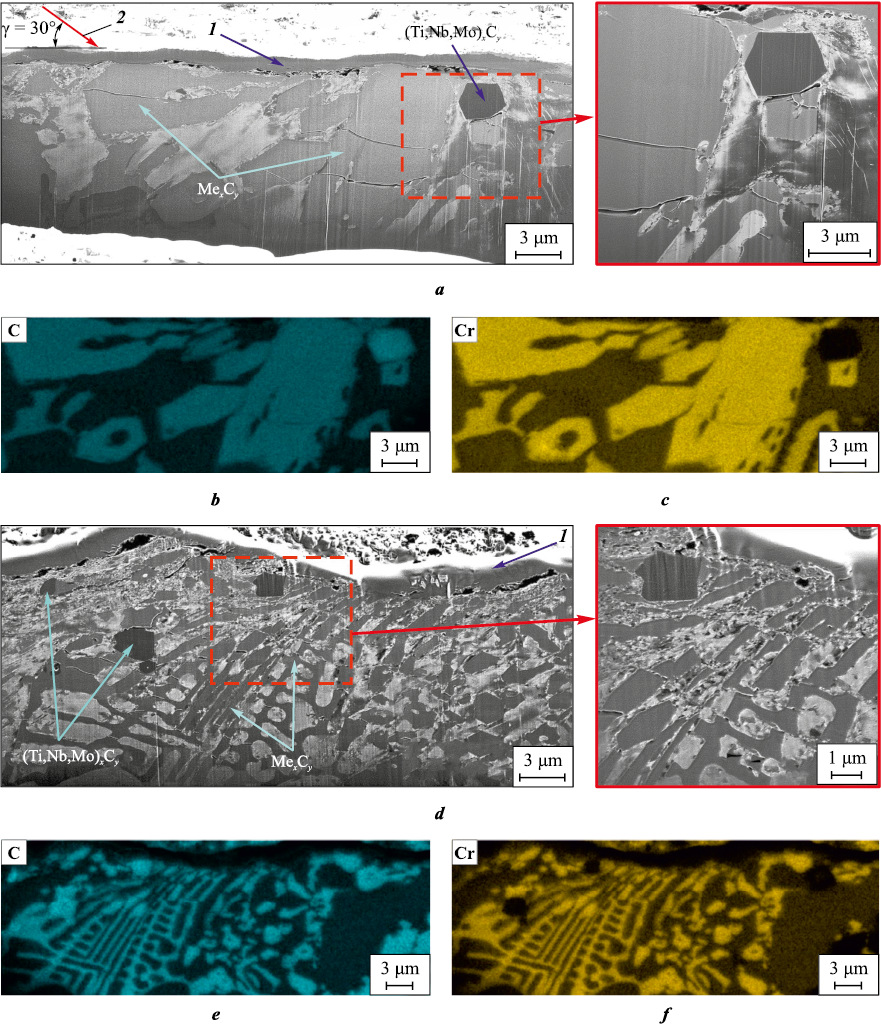

It was revealed (Fig. 7) that, as a result of the high-temperature gas-abrasive flow, a deformed layer forms on the surface of the coatings, which can be identified in cross-sections of worn samples obtained by ion etching. Under the impact of abrasive particles, partial destruction of large plate-like MexCy carbides occurs, accompanied by the formation of cracks that open in the direction of the gas-abrasive flow (Fig. 7, a–c). Smaller and more durable (Ti,Nb,Mo)xCy carbides, with their compact shape, shift together with the matrix material without fracturing, limiting its plastic deformation and reducing the coating’s wear rate. The primary wear mechanism appears to be the chipping of relatively large MexCy carbide fragments followed by the shearing of microvolumes of austenite.

Fig. 7. Cross sections of the surface layer of coatings surfaced without USV (a) |

The study of the cross-section of the worn coating surfaced with USV showed (Fig. 7, d) that the processes of intense plastic deformation in the alloy extend to a depth of about 10 µm. Under the impact of abrasive particles, thin MexCy carbide plates crack, and the fragments shift in the direction of impact. At the same time, the solid solution layers dampen shear deformations, and the plastic flow of the austenitic matrix forms a metallic binder around the resulting carbide fragments, reducing the likelihood of their chipping. This is likely also facilitated by the increase in the austenite volume in the structure of the modified coating, as well as the enhancement of its heat resistance due to the increased chromium content.

Conclusions

1. It has been established that ultrasonic treatment of the weld pool during electric arc surfacing affects the crystallization processes of the wear-resistant coating, contributing to the reduction in volume fraction and refinement of primary and eutectic MexCy carbides, increasing the volume of the austenitic matrix by 25 %, and leading to the appearance of (Ti,Mo)xCy and TiC carbides in the structure. This is accompanied by the redistribution of alloying elements between the strengthening phases and the austenite, which affects their mechanical properties. The chromium content in austenite increases by 20 %, while it decreases in MexCy carbides. Meanwhile, the concentrations of molybdenum and manganese in austenite decrease, while they increase in MexCy carbides. Additionally, the titanium content increases in (Ti,Nb,Mo)xCy carbides, and the molybdenum content decreases significantly.

2. The structural changes in the coating caused by USV lead to an 18 % increase in its resistance to gas-abrasive wear at 600 °C, exceeding the performance of international industrial counterparts. This is explained by the formation of a fine lamellar carbide eutectic reinforced with ultra-hard (Ti,Nb,Mo)xCy carbides, which limits the intense plastic deformation of the alloy during wear, confining it to a depth of 10 µm. The negative effect of MexCy carbide cracking under the impact of abrasive particles is mitigated by the increased volume and heat resistance of the austenite, whose plastic flow forms a metallic binder around the carbide fragments, reducing the likelihood of their chipping.

References

1. Sokolov G.N., Lysak V.I. Surfacing of wear-resistant alloys on press dies and tools for hot deformation of steels. Volgograd: Politekhnik, 2005. 284 p. (In Russ.).

2. Pawar S., Jha A.K., Mukhopadhyay G. Effect of different carbides on the wear resistance of Fe-based hardfacing alloys. International Journal of Refractory Metals and Hard Materials. 2019;78:288–295. https://doi.org/10.1016/j.ijrmhm.2018.10.014

3. Jindal C., Sidhu B.S., Kumar P., Sidhu H.S. Performance of hardfaced/heat treated materials under solid particle erosion: A systematic literature review. Materials Today: Proceedings. 2022;50(5):629–639. https://doi.org/10.1016/j.matpr.2021.03.441

4. Kleis I., Kulu P. Solid particle erosion: occurrence, prediction and control. London: Springer, 2008. 206 p. https://doi.org/10.1016/10.1007/978-1-84800-029-2

5. Fortini A., Suman A., Zanini N. An experimental and numerical study of the solid particle erosion damage in an industrial cement large-sized fan. Engineering Failure Analysis. 2023;146:107058. https://doi.org/10.1016/j.engfailanal.2023.107058

6. Roy M. Elevated temperature erosive wear of metallic materials. Journal of Physics D: Applied Physics. 2006;39(6): 101–124. https://doi.org/10.1088/0022-3727/39/6/R01

7. Ricardo G.A.N., Sommerfeld M. Comprehensive Euler/Lagrange modelling including particle erosion for confined gas-solid flows. Particuology. 2024; 84:209–235. https://doi.org/10.1016/j.partic.2023.06.010

8. Zhou L., Li T., Liu Z., Ma H., Xu C., Dong Y., Zhao Y. An impact energy erosion model with an energy allocation rule for the discrete element method. Wear. 2024;540–541: 205233. https://doi.org/10.1016/j.wear.2023.205233

9. Tarodiya R., Levy A. Surface erosion due to particle-surface interactions – A review. Powder Technology. 2021;387:527–559. https://doi.org/10.1016/j.powtec.2021.04.055

10. Krupicz B., Tarasiuk W., Barsukov V.G., Sviridenok A.I. Experimental evaluation of the influence of mechanical properties of contacting materials on gas abrasive wear of steels in sandblasting systems. Journal of Friction and Wear. 2020; 41(1):5–11. https://doi.org/10.3103/S1068366620010110

11. Priyatkin D.V., Artem’ev A.A., Lysak V.I., Loiko P.V. Analysis of hardfacing alloys for work in conditions of gas-abrasive wear at elevated temperatures. Izvestiya Volgogradskogo gosudarstvennogo tekhnicheskogo universiteta. 2020; 10(245):49–55. (In Russ.). https://doi.org/10.35211/1990-5297-2020-10-245-49-55

12. Qin Z., He D., Ma L., He C., Wu X., Wang, G. Influence of Ni additions on microstructure, non-magnetic properties, and wear resistance of Fe–Mn–Cr alloy deposited by metal-cored arc welding. Welding in the World. 2024; 68:699–714. https://doi.org/10.1007/s40194-024-01694-9

13. Chernyshov G.G., Kobernik N.V., Orlik A.G., Chernyshova T.A. The influence of the structure of the deposited coatings on the resistance to abrasive wear. Fizika i khimiya obrabotki materialov. 2011;(5):44–50. (In Russ.).

14. Eremin E.N., Losev A.S., Borodikhin S.A., Matalasova A.E., Ponomarev I.A. Powder wire for surfacing corrosion-resistant and wear-resistant steel. Vestnik mashinostroeniya. 2018;(7):66–68. (In Russ.).

15. Saraev Yu.N., Lebedev V.A., Novikov S.V. Analysis of existing methods for controlling the structure of the weld metal. Russian Internet Journal of Industrial Engineering. 2016;4(1):16–26. (In Russ.).

16. Fan Z., Bai K., Chen C. The application of ultrasound in Joining: Principles, processes and properties. Journal of Manufacturing Processes. 2023;101:269–299. https://doi.org/10.1016/j.jmapro.2023.05.094

17. Mohsan A.U.H., Zhang M., Wang D., Zhao S., Wang Y., Chen C., Zhang J. State-of-the-art review on the Ultrasonic Vibration Assisted Laser Cladding (UVALC). Journal of Manufacturing Processes. 2023;107:422–446. https://doi.org/10.1016/j.jmapro.2023.10.066

18. Zhang K., Gao G., Zhao C., Wang Y., Wang Y., Li, J. Review of the design of power ultrasonic generator for piezoelectric transducer. Ultrasonics Sonochemistry. 2023;96:106438. https://doi.org/10.1016/j.ultsonch.2023.106438

19. Chang L., Yanpeng Y., Zhaotai L., Xin H., Tenghui J. Differential analysis of the influence mechanism of ultrasonic vibrations on laser cladding. CIRP Journal of Manufacturing Science and Technology. 2022;38:16–37. https://doi.org/10.1016/j.cirpj.2022.03.009

20. Kudina A.V., Kurash V.V., Redin I.V., Khrolenok V.V. Obtaining wear-resistant metal coatings by electric arc surfacing with a melting electrode when exposed to ultrasound. Agropanorama. 2013;3(97):34–38. (In Russ.).

21. Minin S.I., Trofimov A.I., Trofimov M.A. The technology of thermal welding of the circulation piping of NPPS containing the influence of ultrasound. Izvestiya vuzov. Yadernaya energetika. 2016;(4):5–11. (In Russ.). https://doi.org/10.26583/npe.2016.4.01

22. Priyatkin D.V., Artem’ev A.A., Sokolov G.N., Lysak V.I., Odnogulov R.M., Loiko P.V. Аnalysis of the methods of introducing the ultrasonic vibrations in the weld pool in the process of arc surface and development devices for its implementation. Izvestiya Volgogradskogo gosudarstvennogo tekhnicheskogo universiteta. 2019;4(227):68–75. (In Russ.).

23. Wang Y., Yu C., Lu H., Chen J. Research status and future perspectives on ultrasonic arc welding technique. Journal of Manufacturing Processes. 2020;58:936–954. https://doi.org/10.1016/j.jmapro.2020.09.005

24. Fattahi M., Ghaheri A., Arabian N., Amirkhanlu F., Moayedi H. Applying the ultrasonic vibration during TIG welding as a promising approach for the development of nanoparticle dispersion strengthened aluminum weldments. Journal of Materials Processing Technology. 2020;282:116672. https://doi.org/10.1016/j.jmatprotec.2020.116672

25. Priyatkin D.V., Artemyev A.A., Lysak V.I. Investigation of the surfaced metal of the Fe–Cr–Ni–Mn–Mo–Ti–Nb–C system for operation under high-temperature gas-abrasive wear. Voprosy Materialovedeniya. 2022;3(111):17–28. (In Russ.). https://doi.org/10.22349/1994-6716-2022-111-3-17-28

26. Artem’ev A.A., Sokolov G.N., Zorin I.V., Lysak V.I., Rykov M.A., Krutenko A.V., Shnipko M.V. Method of tested weld metal for gas-abrasive wearing. Izvestiya Volgogradskogo gosudarstvennogo tekhnicheskogo universiteta. 2018;3(213):112–116. (In Russ.).

27. Priyatkin D.V., Artemyev A.A., Lysak V.I., Tsyganok S.N. Electric arc cladding of wear-resistant alloys with ultrasonic action on the weld pool. Svarka i diagnostika. 2023;(5):20–26. (In Russ.).

28. Sun S., Fu H., Ping X., Guo X., Lin J., Lei Y., Zhou J. Formation mechanism and mechanical properties of titanium-doped NbC reinforced Ni-based composite coatings. Applied Surface Science. 2019;476:914–927. https://doi.org/10.1016/j.apsusc.2019.01.171

About the Authors

D. V. PriyatkinRussian Federation

Dmitriy V. Priyatkin – Cand. Sci. (Eng.), Senior Lecturer, Department of Equipment and Welding Production

28 Lenin Prosp., Volgograd 400005, Russia

A. A. Artem’ev

Russian Federation

Aleksandr A. Artem’ev – Cand. Sci. (Eng.), Associate Professor, Department of Equipment and Welding Production

28 Lenin Prosp., Volgograd 400005, Russia

V. I. Lysak

Russian Federation

Vladimir I. Lysak – Dr. Sci. (Eng.), Professor, Academician of the Russian Academy of Sciences, Head of the Department of Equipment and Welding Production, Scientific Director

28 Lenin Prosp., Volgograd 400005, Russia

Review

For citations:

Priyatkin D.V., Artem’ev A.A., Lysak V.I. Formation of wear-resistant coatings during electric arc surfacing with ultrasonic vibrations. Powder Metallurgy аnd Functional Coatings (Izvestiya Vuzov. Poroshkovaya Metallurgiya i Funktsional'nye Pokrytiya). 2024;18(5):44-54. https://doi.org/10.17073/1997-308X-2024-5-44-54

JATS XML