Scroll to:

Evaluation of the stress state in a cold-pressed seal briquette for a gas compressor unit

https://doi.org/10.17073/1997-308X-2025-1-23-29

Abstract

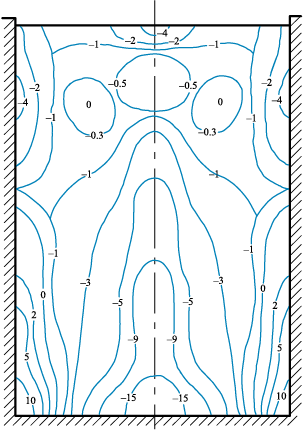

The finite element method is employed to analyze the distribution of residual stresses in axisymmetric preforms of a gas compressor seal at the final stage of compaction. A computational scheme is presented, based on the obtained data on equivalent stress isolines. The dependence of the stress-strain state on the contact conditions between the compact and the die during pressing is examined. The obtained data illustrate equivalent stress isolines (MPa) according to the Mirolyubov criterion. It was established that in various sections, the stress state approaches the critical limit, which may lead to visible fracture of the briquette and delamination of its lateral surface. This finding confirms the results of previous studies on obtaining high-density powder compacts via single-step cold pressing. When solving the problem of producing a high-density powder component, the initial input data included a previously known stress distribution in the compacted briquette. Such data can be obtained from widely established methodologies, particularly for cold pressing in rigid dies for components with complex geometries. The stress-strain state of the powder briquette was computed at the contact surface between the compact and the rigid die under high and infinite friction conditions. In certain regions, significant stress levels can provoke hidden or visible failure, such as rupture of the “terminal layer” or delamination of the lateral surface. The results of numerical investigations are also applicable to low-modulus powder materials compacted in massive dies. The described method for calculating residual stresses was developed using a specialized IBM software program and was utilized for stress state analysis of compacted preforms under elastic unloading conditions.

Keywords

For citations:

Jafarova A.A. Evaluation of the stress state in a cold-pressed seal briquette for a gas compressor unit. Powder Metallurgy аnd Functional Coatings (Izvestiya Vuzov. Poroshkovaya Metallurgiya i Funktsional'nye Pokrytiya). 2025;19(1):23-29. https://doi.org/10.17073/1997-308X-2025-1-23-29

Introduction

The production of parts and semi-finished products from metal and other powders in a closed mold through cold pressing of unsintered briquettes is accompanied by the formation of significant technological stresses. After the upper pressing punch is removed, the briquette in the die undergoes elastic “expansion” , which primarily occurs due to a sudden change in the stress-strain state of the “green” compact. As is well known, such tensile stresses can lead to the failure of an entire region or the upper layer of the compact [1; 2]. Based on literature data, it can be noted that the elastic springback behavior in pressed parts remains insufficiently studied [1–3]. In this regard, considering the aforementioned phenomenon, the development of a methodology for calculating the stress-strain state of compacted products is a relevant problem for predicting their strength. The quality of sintering is determined at the stage of the “green” compact, depending on various temperature regimes of cold pressing and heating conditions. Studies [4–6] have shown that during high-pressure compaction of iron-based mixtures, gas (air) evacuation from the compacted briquette becomes difficult.

The main objective of this study was to analyze the distribution of residual stresses at the final stage of cold pressing in axisymmetric powder preforms of a gas compressor seal.

Residual stress evaluation

The distribution of residual stresses in axisymmetric compacts of the seal was analyzed using the finite element method after punch removal. The analytical approach is significantly complicated by the physical nonlinearity of this problem. The proposed algorithm considers the stress state of the compact at the final stage of densification, along with the elastic relaxation of contact (including force and kinematic factors) and other conditions in the compacted briquettes. High tensile pressures arise, which, upon release of the compact from the die, lead to significant loosening and even fracture of the briquette. Therefore, in [7], a device and method were proposed to enhance air drainage from the pressing zone during high-pressure compaction of a powder mixture. Accordingly, obtaining high-density powder products requires knowledge of residual stress levels in different regions of the compact. This information serves as the basis for constructing a further technological chain for manufacturing high-density powder products of complex geometry.

During the elastic relaxation process, the stress state of the compact was determined by formulating a finite element problem using the finite element method, which includes:

– the variational Lagrange equation [8–10]:

| \[{\int_V {\delta \left\{ \varepsilon \right\}} ^T}\left\{ \sigma \right\}dv - \int_{{S_f}} \delta \left\{ u \right\}_{{S_f}}^T{\left\{ F \right\}_f}d{S_f} = 0;\] | (1) |

– the material equation accounting for initial stresses:

| \[\left\{ \sigma \right\} = \left| \begin{array}{l}{\sigma _\varphi }\\{\sigma _T}\\{\sigma _z}\\{\tau _{rz}}\end{array} \right| = \left[ B \right]\left\{ \varepsilon \right\} + \left\{ {{\sigma ^0}} \right\};\] | (2) |

| \[\left\{ \varepsilon \right\} = \left| \begin{array}{l}{\varepsilon _\varphi }\\{\varepsilon _r}\\{\varepsilon _z}\\{\gamma _{rz}}\end{array} \right| = \left[ L \right]\,\,\left\{ u \right\};\] | (3) |

where \(\left[ L \right] = \left| \begin{array}{l}\frac{1}{r}\,\,\,\,\,\,\,\,0\\\frac{\partial }{{\partial \,r}}\,\,\,\,\,0\\0\,\,\,\,\,\frac{\partial }{{\partial \,z}}\,\\\frac{\partial }{{\partial \,z}}\,\,\frac{\partial }{{\partial r}}\end{array} \right|\) is the differential operator;

– the displacement approximation equation within the element nodes is given by:

| \[\left\{ u \right\}\, = \,\left\{ \begin{array}{l}{u_r}\\{u_z}\end{array} \right\} = \left[ N \right]\left\{ x \right\}\, = \,\left[ N \right]\,\left\{ \begin{array}{l}{x_i}\\{x_j}\\{x_R}\end{array} \right\};\] | (4) |

– the contact conditions in the “compact–die” system, considering frictional forces at the contact surface:

| \[{\left\{ F \right\}_f} = f\left\{ {{\sigma _n}} \right\}\,{S_f}.\] | (5) |

The kinematic problem (contact condition), which refers to the necessary unilateral boundary conditions, is taken into account in the analysis and model construction [11]. For a rigid die, these conditions can be formulated as “impermeability conditions”:

| \[\begin{array}{c}{\left\{ {{u_r}} \right\}_{r = R}} = 0{\rm{ }}...{\rm{ }}{\left\{ {{\sigma _r}} \right\}_{r = R}} < 0,\\{\left\{ {{u_z}} \right\}_{z = 0}} = 0{\rm{ }}...{\rm{ }}{\left\{ {{\sigma _z}} \right\}_{z = 0}} < 0;\end{array}\] | (6) |

| \[\begin{array}{c}{\left\{ {{u_r}} \right\}_{r = R}} < 0{\rm{ }}...{\rm{ }}{\left\{ {{\sigma _r}} \right\}_{r = R}} > 0,\\{\left\{ {{u_z}} \right\}_{z = 0}} > 0{\rm{ }}...{\rm{ }}{\left\{ {{\sigma _z}} \right\}_{z = 0}} > 0.\end{array}\] | (7) |

In equations (1)–(7), the parameters are defined as follows: {σ}, {ε} – tensors of residual stresses and strains, respectively; \(\left\{ {{\sigma ^0}} \right\}\) – stress tensor in the compact at the final moment of densification; \({\left\{ u \right\}_{{S_f}}}\) – displacement vector of the element nodes on the friction surface (between the compact and the die at initial and final moments); [B], [N] – the elastic constant matrix of the compact material and the shape function of the finite element, determined based on [12]; {F}f – friction force acting on the uniform contact surface; {x} – displacement vector of the finite element nodes; f – friction coefficient; {σn}Sf – normal stresses at the “compact–die” contact surface; x, T, δ – operators of multiplication, transposition, and variation, respectively.

Considering equations (2)–(4), equation (1) can be rewritten in the standard form for the finite element method:

| \[\left[ K \right]\,\left\{ x \right\} = \,{\left\{ R \right\}_{{\sigma ^0}}} + {\left\{ R \right\}_f},\] | (8) |

where [K] is the global stiffness matrix [11]; \({\left\{ R \right\}_{{\sigma ^0}}} = \int {{{\left[ B \right]}^T}\{ {\sigma ^0}\} } \,\,dv\) is the nodal force vector arising from the presence of stresses \(\left\{ {{\sigma ^0}} \right\}\) in the compact; [B] = [L][N]; \({\left\{ R \right\}_f} = \int\limits_{{S_f}} {{{\left[ N \right]}^T}} {\left\{ F \right\}_f}d{S_f}\) is the nodal forces dependent on frictional forces.

Thus, the problem formulated in equations (1)–(7) is reduced to solving the system of linear algebraic equations (8), considering the displacement of finite element nodes [13].

However, due to the uncertainty of vector {R}f , the problem is generally nonlinear. Therefore, an iterative method is proposed, based on sequential solutions of classical elasticity theory with friction force corrections and validation of constraints (6) and (7) at a specific stage.

At the first step, the nodal force vector \({\left\{ R \right\}_{{\sigma ^0}}}\) and the friction force {R}f are applied to the element nodes, using the normal stress distribution in the zone \(\left\{ {{\sigma ^0}} \right\}\). Solving equation (8) yields the components {x}, {σ}, {g} of the stress-strain state of the compact, corresponding to the removal of the upper punch under the influence of frictional forces initially acting on the briquette surface [14]. By adjusting the friction force vector {σ}1 to match the updated normal stresses, the procedure is repeated until the desired accuracy is achieved. Furthermore, as numerical experiment indicates, it is advisable to verify connectivity conditions, while the “impermeability” conditions (6) and (7) remain satisfied throughout the solution process. Ultimately, after removing the externally applied pressing forces from the initial stress state \(\left\{ {{\sigma ^0}} \right\}\), the residual stress distribution and strain state of the compact are obtained [15].

In solving the stated problem, the input data consisted of a previously known stress distribution in the compacted briquette. Such data can be obtained from several widely established methodologies, particularly for cold pressing in rigid dies [16; 17]. A similar approach was applied in our study.

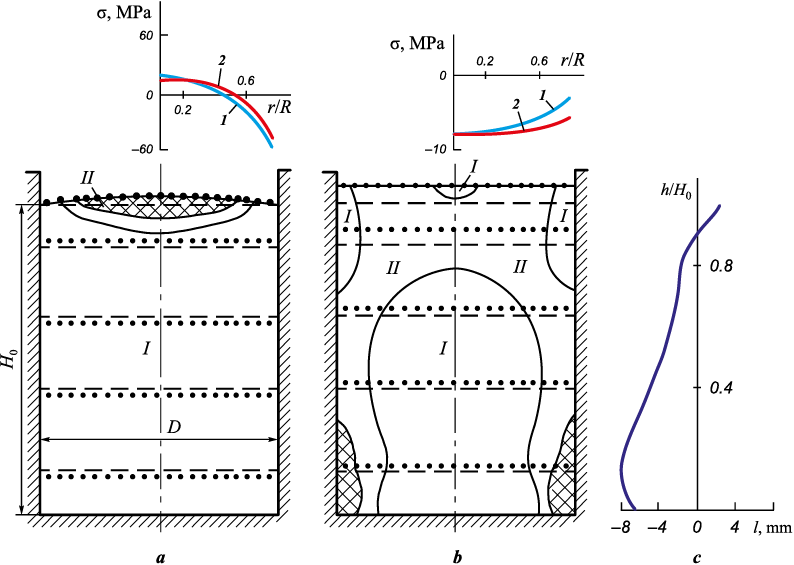

For example, for H0 /D = 1.5, where H0 is the height of the compressed cylinder and D is its diameter (Fig. 1), the stress-strain state of a proportionally cylindrical seal for a gas compressor unit was investigated [18]. The semi-finished product was obtained by pressing an iron-based composite powder containing 2 wt. % graphite powder under a maximum pressure of Р = 1000 using a punch.

Fig. 1. Calculation scheme |

The friction coefficient was determined from the following relationship

| \[f = A + B\sigma _0^{\rm{c}},\] | (9) |

where А and В are material constants, and \(\sigma _0^{\rm{c}}\) is the mean pressure in the elements of the contact layer.

In the calculations, the average values of the material’s elastic constants were used for the entire volume of the compact: Young’s modulus Е = 4 GPa and Poisson’s ratio v = 0,4.

The discretization of the axisymmetric preform was performed using circular elements of triangular cross-section. The finite element mesh was refined in regions with the highest stress concentrations, specifically on the lateral surface and the free end of the compact [19].

A stress-strain state analysis was conducted for different force conditions at the “compact–rigid die” contact interface (Fig. 2, a, b): for high-friction conditions, where the axial displacement of points on the compact’s contact surface was restricted, i.e. \({\left\{ {{u_x}} \right\}_{{S_f}}} = 0\) and for friction defined by equation (5), where \({\left\{ {{u_x}} \right\}_{{S_f}}}\) is infinite.

Fig. 2. Dependence of the stress-strain state of the compact on contact conditions with the die |

Fig. 2 illustrates the “natural” shape of the preform after unloading. The dashed lines represent certain sections of the compact before unloading, while the dotted lines indicate the positions of the finite element nodes of the same sections after punch removal.

The calculations show that stress redistribution is often accompanied by the development of internal tensile stresses [20]. For example, in the zone I elements, we have σ1 > 0, while in the shaded zone II – σ1 > 0, σ0 > 0, (see Fig. 2, a), where σ1 is the highest stress in the rz-plane, and σ0 is the mean normal stress (I – compression zone).

In the elements of the surface layer, both radial stress (σT ) and circumferential stress (σφ ) were positive. Curves 1, 2 in Fig. 2 represent variations in these stresses along the free end surface of the seal. The stress state of the briquette is characterized by a well-developed σ1 > 0 zone under unloading conditions close to real scenarios, by stress concentration σ1 > 0, σ0 > 0, in the closed “corners” of the compact, and by the occurrence of tensile stresses σφ in the lateral layer of the open end (Fig. 2, c).

To assess the strength of the compact after elastic unloading, the Mirolyubov criterion is used in the following form [21]:

| \[{\sigma _e} = \frac{{3(1 - \lambda )}}{2}{\sigma _0} + \frac{{1 + \lambda }}{2}{\sigma _i},\] | (10) |

where σi is the stress intensity, and \(\lambda = \sigma _d^p/\sigma _d^s\), \(\sigma _d^s\) are the boundary stresses under simple tension and compression conditions.

Fig. 3 shows the distribution of residual equivalent stresses σe under unloading conditions at λ = 0.15 [22]. The highest stress concentration in the compact occurs in the bottom volume after punch removal: tensile stresses develop in the wall layers, while compressive stresses dominate in the central region.

Fig. 3. Isolines of equivalent stresses according |

In these regions, the stress state is close to the critical limit and may lead to either hidden or visible failure, such as rupture of the “terminal layer” or delamination of the lateral surface [23].

It should be noted that the results of the numerical investigations are also applicable to low-modulus powder materials compacted in massive dies.

Conclusion

The finite element analysis established the stress-strain state of the compact at the final stage of cold pressing. This problem was reduced to solving a system of linear algebraic equations while accounting for the displacement of finite element nodes. It was revealed that the highest stress concentration in the compact occurs in the bottom volume after punch removal, with tensile stresses in the wall layers and compressive stresses in the central part of the compact.

References

1. Griqoriev S.N., Dmitriev A.M., Korobova N.V., Fedorov S.V. A cold-pressing method combining axial and shear flow of powder compaction to produce high-density iron parts. Technologies. 2019;7(4):70. https://doi.org/10.3390/technologies7040070

2. Dmitriev A.M., Korobova N.V., Badalyan A.Z. Development and research of formation technologies on specialized presses with subsequent sintering of high-density details from iron-based powders. Journal of Mining Institute. 2019;236:216–228. https://doi.org/10.31897/PMI.2019.2.216

3. Ferreira S.C., Conde A., Arenas M.A., Rocha L.A., Velhinho A. Anodization mechanism on SiC nanoparticle reinforced al matrix composites produced by power metallurgy. Materials. 2014;7(12):8151–8167. https://doi.org/10.3390/ma7128151

4. Chauhan S., Verma V., Prakash U., Tewari P.C., Khanduja D. Studies on induction hardening of powder-metallurgy-processed Fe–Cr/Mo alloys. International Journal of Minerals Metallurgy and Materials. 2017;24(8):918–925. https://doi.org/10.1007/s12613-017-1478-2

5. Mamedov A.T., Mamedov V.A. Phenomenological approach to the plastic deformation of metallic powders in confined cavity. News of ANAS: Science and Innovation Series. 2012;1(9):67–72.

6. Dmitriev A.M., Korobova N.V. A study of advanced processes for large-scale production of parts from powder steels. Metal Science and Heat Treatment. 2018; 60(7):457–463. https://doi.org/10.1007/s11041-018-0301-7

7. Jafarova A.A. Compaction of elastoplastic iron batch in pressing. Russian Engineering Research. 2023;43(9): 1095–1100. https://doi.org/10.3103/S1068798X23090101

8. Montes J.M., Cuevas F.G., Cintas J., Torres Y. Powder compaction law for cold die pressing. Journal Granular Matter. 2010;12(6):617–627. https://doi.org/10.1007/s10035-010-0203-x

9. Xu C., Liu F., Huang L., Jiang L. Dependence of creep performance and microstructure evolution on solution cooling rate in a polycrystalline superalloy. Metals. 2018;8(1):4. https://doi.org/10.3390/met8010004

10. Mammadov A., Mammadov V. Comparative analysis of diffusion metallization coatings applied on steel parts. Metallurgical and Materials Engineering. 2023; 29(4):43–54. https://doi.org/10.56801/MME1020

11. Justino J.G., Alves M.K., Klein A.N., Al-Qureshi H.A. Constutive model for the elastic-plastic analysis of porous sintered materials. International Journal of Machine Tools Manufacture. 2004;44(14):1471–1479. https://doi.org/10.1016/j.ijmachtools.2004.05.006

12. Al-Qureshi H.A., Galiotto A., Klein A.N. On the mechanics of cold die compaction for powder metallurgy. Journal of Materials Processing Technology. 2005;166(1): 135–143. https://doi.org/10.1016/j.jmatprotec.2004.08.009

13. Mamedov A.T., Rustamova S.M. Influence of intermediate sintering temperature on the properties of powder materials. Vestnik mashinostroeniya. 2018;(2):48–51. (In Russ.).

14. Bogatov A.A. Residual stresses and metal facture. In: Innovative technologies in metallurgy and mechanical engineering: Proceedings of the 6th Intern. youth scientific and practical conferences (Ekaterinburg, 29 October – 1 November, 2012). Ekaterinburg: Publ. Ural. University, 2013. P. 95–101. (In Russ.). https://elar.urfu.ru/handle/10995/33248

15. Gnuchii Yu.B. To the solution of contact problems of the theory of elasticity and plasticity. Problemy prochnosti. 2012;(12):99–104. (In Russ.).

16. Generalov M.B., Stepanova A.R. Study of the compaction process of powder materials in a blind matrix. BMSTU Journal of Mechanical Engineering. 1988;(11):110–114. (In Russ.).

17. Radomyselsky I.D., Pechentkovsky E.L. Influence of the pressing tool on the density distribution in metal-ceramic materials such as bushings. Powder Metallurgy. 1970;(4):13–19. (In Russ.).

18. Dvilis E.S., Chartpuk P., Khasanov O.L., Sokolov V.M., Eshetov B.A. Analytical and model optimization of kinematic schemes of uniformly dense pressing of powder materials. Bulletin of the Tomsk Polytechnic University. 2013;323(2):49–55. (In Russ.).

19. Koshlyakov N.S., Gliner E.B., Smirnov M.M. Partial differential equations of mathematical physics. Moscow: Vysshaya Shkola, 1970, 710 p. (In Russ.).

20. Zenkevich O.K. Finite element method in technology. Moscow: Mir, 1975. P. 426–428. (In Russ.).

21. Pozdnev A.A., Nyashin Yu.I., Trusov V.P. Residual stresses: theory and applications. Moscow: Nauka, 1982. Р. 94–97. (In Russ.).

22. Moskvitin V.V. Resistance of viscoelastic materials. Moscow: Nauka, 2002. P. 76–79. (In Russ.).

23. Kalinnikov A.E., Vakhrushev A.V., Kurguzkin M.G. Durability and creep of a multi-resistance composite under plane stress conditions. In: Abstracts of the 5th All-Union Conference on mechanics of polymer and composite materials. Riga: Zinatne, 2003. Р. 77–80. (In Russ.).

About the Author

A. A. JafarovaAzerbaijan

Afet Arif Jafarova – Cand. Sci. (Eng.), Associate Professor of the Department “Chemical technology, processing and ecology”

25 H. Javid Prosp., Baku, AZ 1073, Azerbaijan

Review

For citations:

Jafarova A.A. Evaluation of the stress state in a cold-pressed seal briquette for a gas compressor unit. Powder Metallurgy аnd Functional Coatings (Izvestiya Vuzov. Poroshkovaya Metallurgiya i Funktsional'nye Pokrytiya). 2025;19(1):23-29. https://doi.org/10.17073/1997-308X-2025-1-23-29

JATS XML